A kind of polishing agent for 3D printing products and its preparation method and polishing method

A 3D printing and polishing agent technology, which is applied in the direction of polishing composition, chemical instruments and methods, etc., can solve the problems of not being able to achieve high gloss, high equipment cost, and limited product size, and achieve unlimited product size and high polishing uniformity , fast polishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

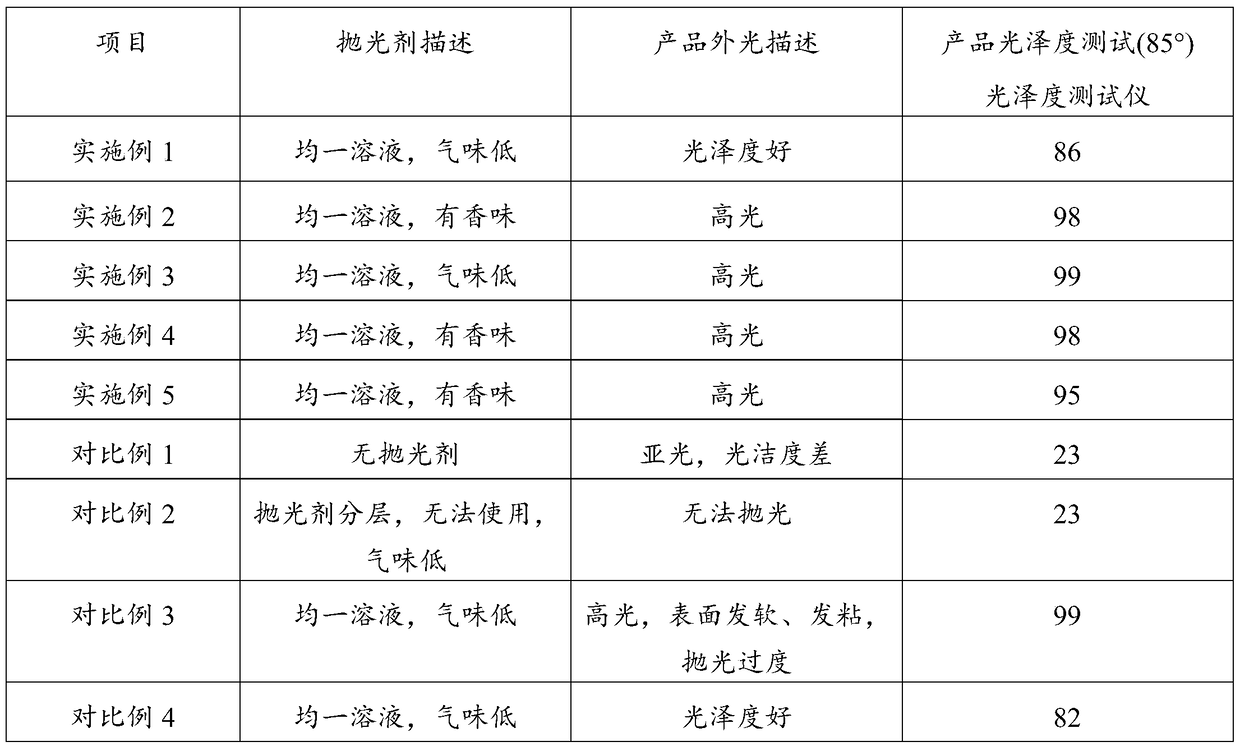

Embodiment 1

[0028] Preparation of polishing agent for FDM 3D printing PS products:

[0029] Step S11: Add 100 g of diethylene glycol tert-butyl ether into 100 g of water, mix and dissolve evenly, and obtain a mixed solution;

[0030] Step S12: Mix and dissolve 1 g of ethylene glycol tert-butyl ether carbonate with the above mixed solution to obtain a polishing agent for 3D printing products.

[0031] Polishing method:

[0032] Step S13: immerse the 3D printed product in the polishing agent to realize dissolution polishing, and the polishing time is 4 hours;

[0033] Step S14: washing and removing the polishing agent on the product surface with water;

[0034]Step S15: drying the product from which the polishing agent has been removed, at a baking temperature of 60°C.

Embodiment 2

[0036] Preparation of polishing agent for FDM 3D printing PMMA products:

[0037] Step S21: Add 1g of absolute ethanol and 2g of rose essence into 1g of water, mix and dissolve evenly, and obtain a mixed solution;

[0038] Step S22: Mix and dissolve 100g of propylene glycol diacetate, 20g of flame retardant BDP and the above mixed solution evenly to obtain a polishing agent for 3D printing products.

[0039] Polishing method:

[0040] Step S23: Shower the polishing agent on the surface of the 3D printed product, stop showering after full contact, and perform dissolving and polishing, and the polishing time is 5s;

[0041] Step S24: washing and removing the polishing agent on the product surface with water;

[0042] Step S25: drying the product from which the polishing agent has been removed, at a baking temperature of 70°C.

Embodiment 3

[0044] Preparation of polishing agent for FDM 3D printing ABS products:

[0045] Step S31: Add 30 g of diethylene glycol ether and 0.5 g of peony essence into 60 g of water, mix and dissolve evenly, and obtain a mixed solution;

[0046] Step S32: Mix and dissolve 30g of ethyl lactate, 2g of flame retardant RDP and the above mixed solution evenly to obtain a polishing agent for 3D printing products.

[0047] Polishing method:

[0048] Step S33: Spray the polishing agent on the surface of the 3D printed product, stop the mist spraying after sufficient contact, and perform dissolution polishing for 1 minute;

[0049] Step S34: washing and removing the polishing agent on the product surface with water;

[0050] Step S35: drying the product from which the polishing agent has been removed, and air-drying naturally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com