Oval reel for producing wound capacitor unit core and wound capacitor unit core

A capacitor unit, elliptical technology, applied in the field of elliptical reels and winding capacitor unit cores, can solve the problems of reduced mechanical strength of reels, unsatisfactory dielectric strength and toughness, S-shaped distortion, etc., to eliminate wrinkles and Effect of twisting, best capacitor performance, and reduced dielectric damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing:

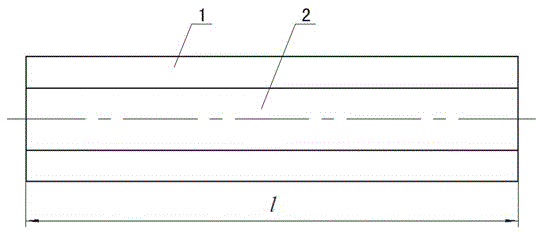

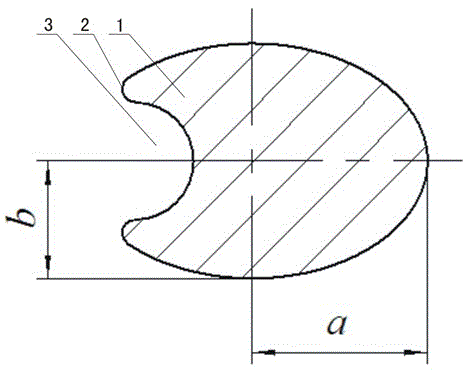

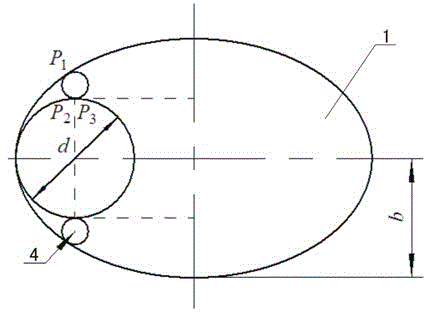

[0026] Such as figure 1 with figure 2 As shown, the radial cross-section of the elliptical reel 1 for producing wound capacitor unit cores according to the present invention is elliptical, and one of the end surface openings of its elliptical major axis forms a guide for installing and exporting (see Figure 4 The guide groove 3 coaxial with the elliptical reel of the export sign 6); the radial section of the guide groove 3 is a circle with an outer opening and its diameter is the same as the length of the radial section ellipse minor axis of the elliptical reel 1, The center of the radial section circle of the guide groove 3 is located on the radial section ellipse major axis of the oval reel 1, the distance between the center of the radial section circle of the guide groove 3 and the virtual ellipse major axis endpoint of the open end of the oval reel 1 The distance i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com