Landfill leachate treatment technology

A technology for landfill leachate and treatment process, applied in the field of landfill leachate treatment technology, can solve the problems of high cost, high continuous operation cost, troublesome leachate proper disposal, etc., and achieves improved biodegradability, comprehensive investment and low operating costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

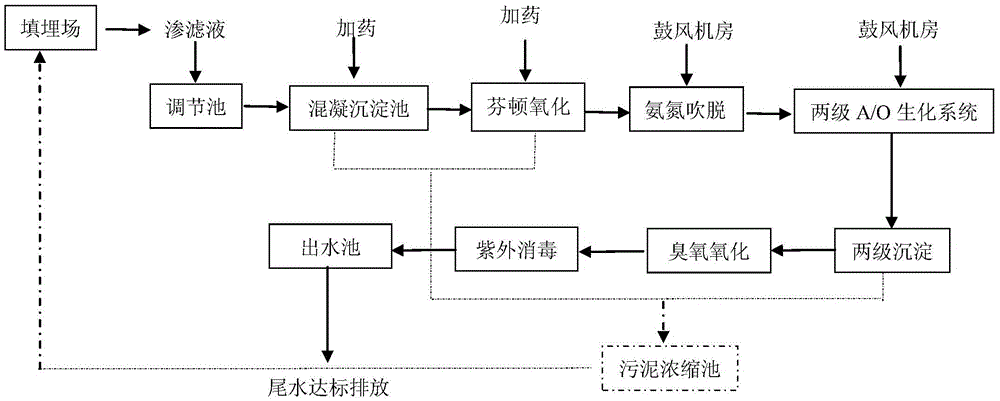

[0024] Such as figure 1 As shown, the present embodiment provides a landfill leachate treatment process, which includes the following steps in turn:

[0025] (1) The landfill leachate flows into the adjustment tank, and the biochemical sludge is mixed in the adjustment tank and stirred to degrade a considerable part of COD;

[0026] (2) The wastewater from the adjustment tank is pumped into the coagulation and sedimentation equipment. Firstly, the wastewater is adjusted to PH4.0, and then coagulant is added to mix and precipitate; a considerable part of pollutants such as COD, SS, heavy metals and chroma are removed.

[0027] (3) The coagulation and sedimentation effluent flows into the Fenton oxidation equipment, and the organic pollutants in the wastewater are catalyzed and oxidized by the Fenton reagent. The refractory organic matter in the wastewa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com