Preparation method of high-light transmittance and self-cleaning polycarbonate sheet

A polycarbonate, self-cleaning technology, applied in the field of materials, can solve problems such as difficult coating, affecting the light transmittance of the sheet, fluorine atom poisoning, etc., achieve good compatibility, improve self-cleaning, high light transmittance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

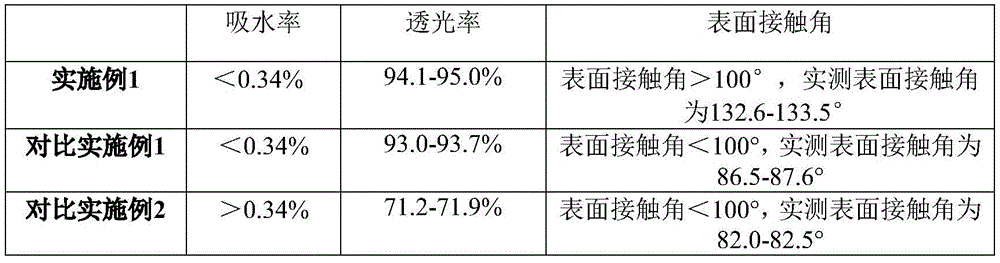

Embodiment 1

[0019] A high-transmittance self-cleaning polycarbonate sheet, made of a polycarbonate substrate and a self-cleaning film, the surface of the self-cleaning film has a micro-nano structure, prepared by coating the self-cleaning film on the polycarbonate substrate A highly light-transmitting self-cleaning polycarbonate sheet is obtained, wherein the polycarbonate substrate is a pure polycarbonate sheet with a thickness of 0.5 cm or 1 cm or 2 cm.

[0020] The preparation method of the highly light-transmitting self-cleaning polycarbonate sheet comprises the following steps:

[0021] Polycarbonate (molecular weight of 80,000-20,000) with a mass ratio of 2:1 or 3.5:1 or 5:1 and hydrophobic nano-silica (particle size of 20-40nm, the mass ratio is 3:1) Hydrophilic fumed silica and hexamethyldisilazane are prepared by alkylation reaction) into tetrahydrofuran (the mass ratio of tetrahydrofuran to polycarbonate is 1:2), ultrasonically or stirred for 30 minutes to form a mixed solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com