Photocatalyst formaldehyde-buster internal wall paint and preparation method thereof

A photocatalyst and aldehyde-cleaning technology, applied in the field of coatings, can solve problems such as dispersion uniformity, adsorption saturation photocatalyst light energy dependence defects, etc., to achieve the effect of strengthening ability, realizing stability and eliminating odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

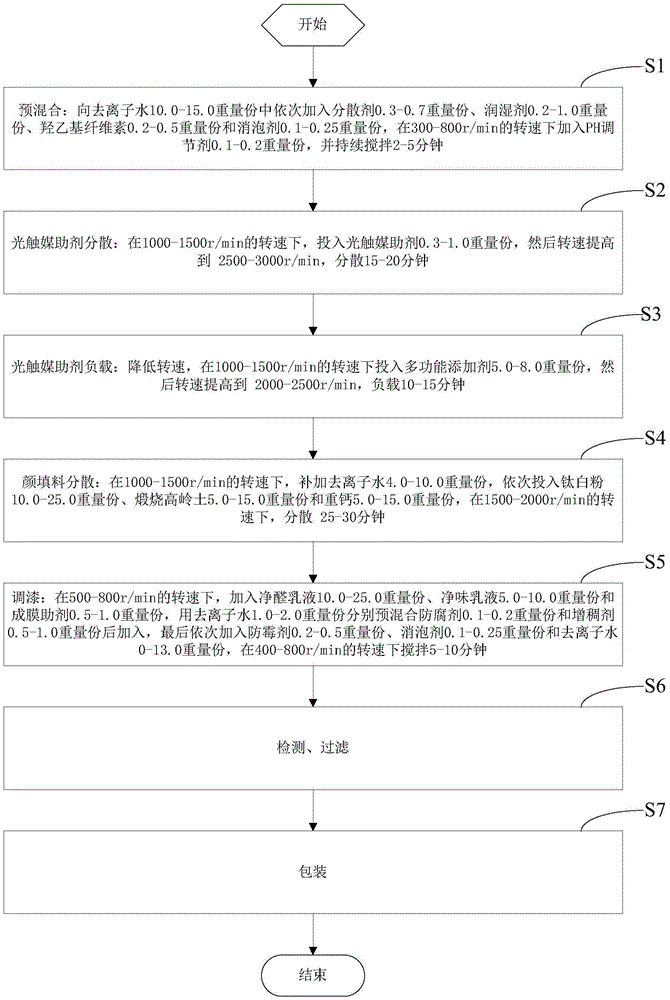

Method used

Image

Examples

Embodiment Construction

[0024] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

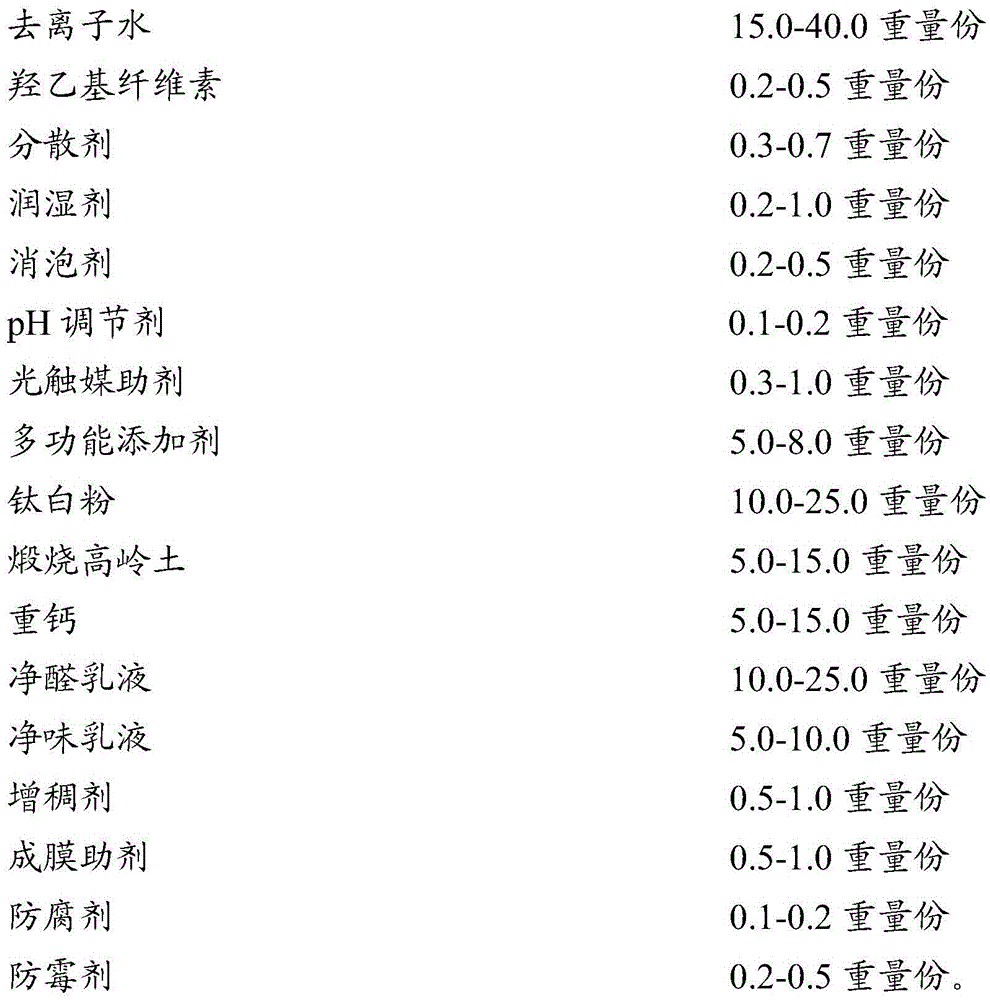

[0025] A kind of photocatalyst net aldehyde interior wall finish paint is provided in the embodiment of the present invention, comprising:

[0026]

[0027] In the present embodiment, the above-mentioned photocatalyst additives include anatase nano-titanium dioxide with a specific surface area of 50m 2 / g, average particle size 21nm, preferably AEROXIDETiO2P25 or HombikatUV100.

[0028] In the present embodiment, above-mentioned multifunctional additive comprises bamboo charcoal particle, structural type universal filler and porous calcined diatomite, the weight ratio of the three is: bamboo charcoal particle: porous calcined diatomite: structural type universal filler=1 :2:5. The specific surface area of the above-mentioned bamboo carbon particles is 300m 2 / g, the maximum particle size is 1.5 μm, the porou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| minimum film forming temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com