A mechanical anode steel claw structure for prebaked aluminum electrolytic cell

An aluminum electrolytic cell and anode steel claw technology, which is applied to the field of aluminum electrolytic anode steel claw, can solve the problems of time-consuming and laborious carbon block replacement process, large contact voltage drop on the connection surface, and reduced electrolysis efficiency, so as to reduce heat loss and save heat energy. , the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

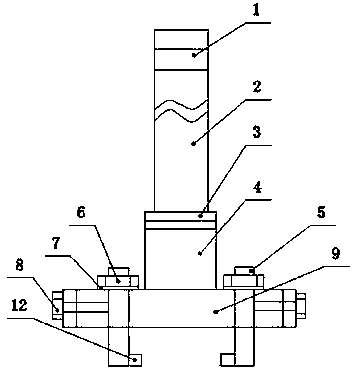

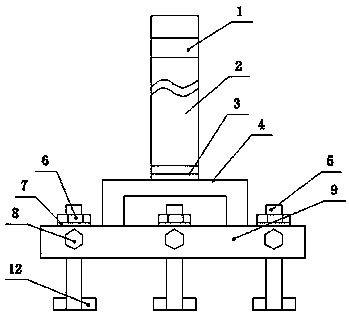

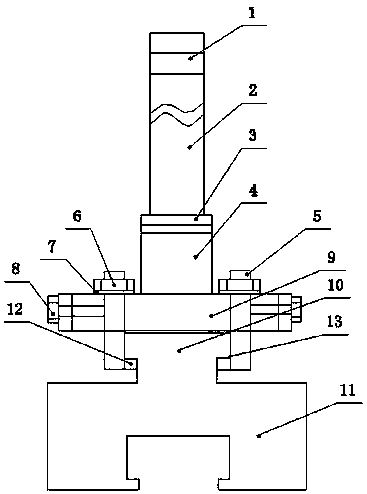

[0023] Embodiment: a kind of mechanical type anode steel claw structure that prebaked aluminum electrolyzer is used, as attached Figure 1-2 As shown, a mechanical steel claw bottom plate 9 is included, and an anode carbon block connection device is provided below the mechanical steel claw bottom plate 9; an anode aluminum guide rod 2 is connected above the mechanical steel claw bottom plate 9.

[0024] A mechanical steel claw bridge foot 4 is provided between the mechanical steel claw bottom plate 9 and the anode aluminum guide rod 2 , and the mechanical steel claw bridge foot 4 is connected to the anode aluminum guide rod 2 through an aluminum-steel explosive welding composite plate 3 .

[0025] The anode carbon block connection device includes movable grooves arranged on both sides of the mechanical steel claw bottom plate 9, the movable groove is provided with mechanical steel claw T-shaped fastening bolts 5, and the mechanical steel claw T-shaped fastening bolts 5 The bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com