Quantitative forecasting method based on shock wave type impact wear rate speed index

A technology of velocity index and prediction method, applied in the field of quantitative prediction of impact wear rate velocity index, can solve the problems of inability to carry out structural optimization, large numerical prediction error of erosion wear rate, etc., to achieve the effect of optimizing design and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with drawings and embodiments.

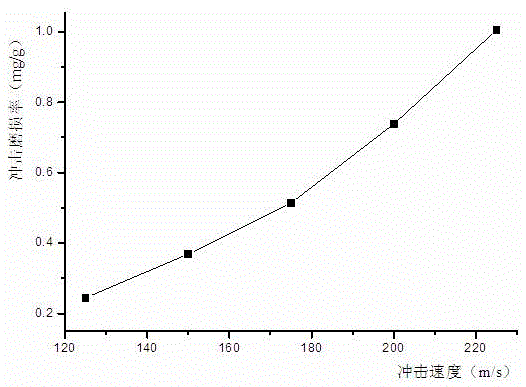

[0032] A shock wave type quantitative prediction method of impact wear rate velocity index includes two parts, one is a drawing method of impact wear rate curve, and the other is a prediction method of impact wear rate velocity index.

[0033] 1) The drawing method of the impact wear rate curve comprises the following steps:

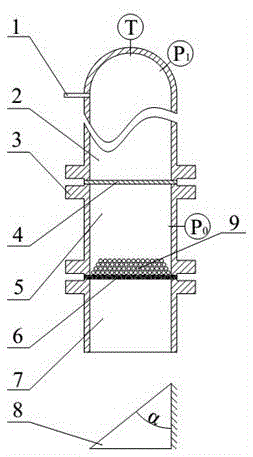

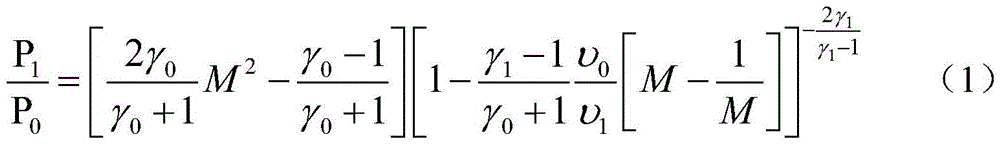

[0034] Step 1.1) According to figure 1 The schematic diagram of the experiment is shown, and the experimental device is installed. Among them, the high-pressure pipe section 2 and the low-pressure pipe section 5 are separated by a non-metallic diaphragm 4, and then connected and fixed by clamp flange 3; the low-pressure pipe section 5 and the particle acceleration section 7 are separated by tin foil 6, and then passed The flange is compressed and fixed, wherein the tin foil 6 is placed with a group of particles 9 . The high-pressure gas cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com