Indium tin oxide (ITO) glass based microbial fuel cell capable of real-time sampling and fabrication method of microbial fuel cell

A real-time sampling and fuel cell technology, applied in biochemical fuel cells, sustainable manufacturing/processing, climate sustainability, etc., can solve the problems of high production cost, time-consuming, complicated production process, etc., to achieve the benefit of processing, Maintain the effect of long-term operation and convenient sampling and analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

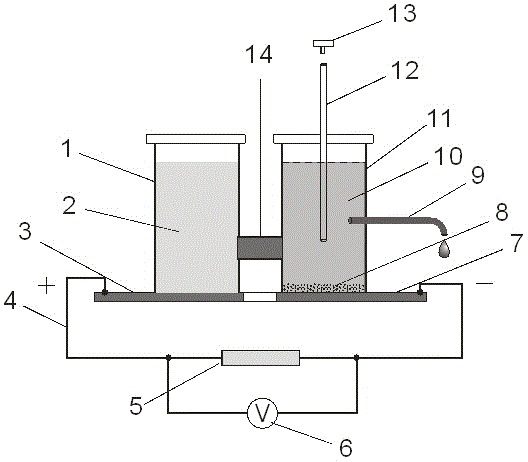

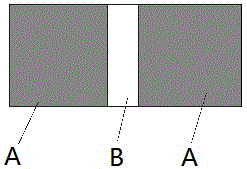

[0028] like figure 1 As shown, a microbial fuel cell based on ITO glass can be sampled in real time, including a cathode chamber 1 equipped with a catholyte 2 and an anode chamber 11 equipped with an anolyte 10, and a salt bridge is connected between the cathode chamber 1 and the anode chamber 11 14. The bottoms of the cathode chamber 1 and the anode chamber 11 are respectively fixed on both sides of the upper surface of the substrate. The substrate is a glass plate with insulating glass in the middle and ITO conductive glass on both sides. One side of the substrate has an ITO conductive layer Set as the cathode plate 3 at the bottom of the cathode chamber 1, one side of the substrate ITO conductive layer is set as the anode plate 7 at the bottom of the anode c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com