Flat-shaped black tea processing method

A processing method, the technology of flat black tea, which is applied in the field of tea processing, can solve the problems of lack of shape and flat black tea, and achieve the effect of rich ingredients, good quality, and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

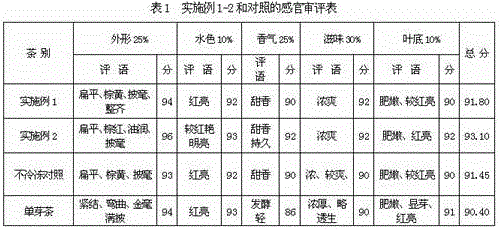

Examples

Embodiment 1

[0023] 1) Selection of raw materials for fresh leaves: choose Yunnan large-leaf species; picking standard: single bud; the length of a single bud is required to be 3cm-4cm, fresh, without damage, with fat and neat bud heads, and high enzyme activity;

[0024] 2) Spread the raw materials in step 1) on the withering rack, the withering thickness is 2cm-3cm, the ambient temperature is controlled at 22°C-30°C, the ambient humidity is controlled at 60%-70%, the withering time is 5h-6h, and it is turned once during the period , until the water content of the withered leaves drops to 71% to 73%, it is advisable to lose part of the grass gas;

[0025] 3) Transfer the raw materials in step 2) into a freezer at -30°C to -20°C for quick freezing for 4h to 5h, and the thickness of the leaves is 2cm to 3cm;

[0026] 4) Transfer the raw materials in step 3) into the green shaker to crush the bud and leaf cells. The speed of the shaker is 55-60 rpm, and the shaker time is 3h-4h;

[0027] 5)...

Embodiment 2

[0032] 1) Selection of raw materials for fresh leaves: choose Yunnan large-leaf species; picking standard: single bud; the length of a single bud is required to be 3cm-4cm, fresh, without damage, with fat and neat bud heads, and high enzyme activity;

[0033] 2) Spread the raw materials in step 1) on the withering rack, the withering thickness is 2cm-3cm, the ambient temperature is controlled at 22°C-30°C, the ambient humidity is controlled at 60%-70%, the withering time is 2h-4h, and it is turned once during the period , until the water content of the withered leaves drops to 73% to 75%, it is advisable to lose part of the grass gas;

[0034] 3) Transfer the raw materials in step 2) into a freezer at -30°C to -20°C for quick freezing for 4h to 5h, and the thickness of the leaves is 2cm to 3cm;

[0035] 4) Transfer the raw materials in step 3) into the green shaker to crush the bud and leaf cells. The speed of the shaker is 55-60 rpm, and the shaker time is 3h-5h;

[0036] 5)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com