SCR catalyst for purifying diesel engine exhaust pollutant and preparation method thereof

A technology for SCR catalysts and pollutants, which is applied in the field of diesel engine exhaust pollutant purification SCR catalysts and its preparation, can solve the problems of low particle removal efficiency, achieve the effects of easy operation, simple preparation method, and improved removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

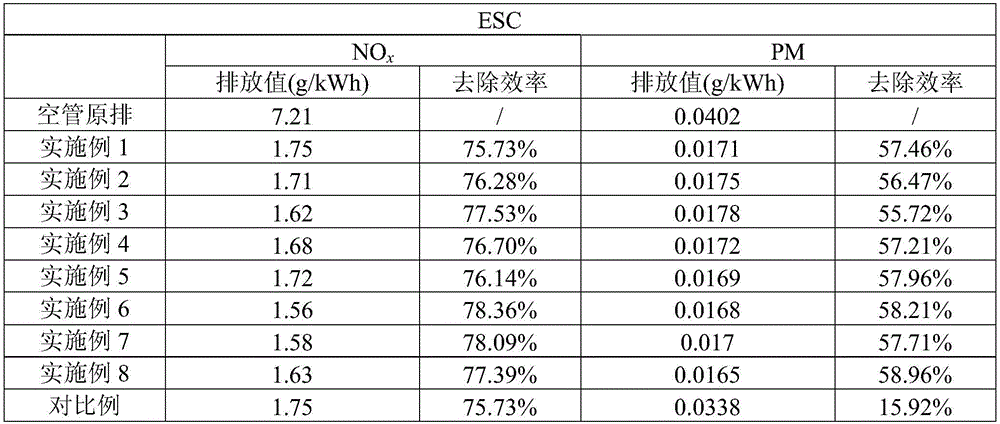

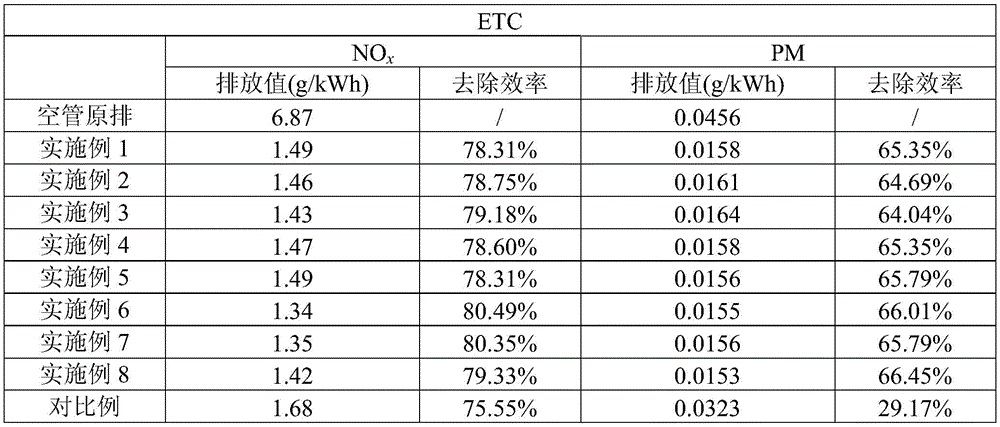

Examples

Embodiment 1

[0028] The catalyst uses 300-mesh cordierite honeycomb ceramics as the carrier, and the size is 1 piece of cylinder with diameter 190.5mm*height 101.6mm (front stage) + 1 piece of cylinder with diameter 190.5mm*height 152.4mm (second stage), with a total volume of 7.22L . A catalytic coating is coated on the surface of the channel of the cordierite honeycomb ceramic carrier. The catalytic coating uses vanadium-cerium-manganese composite oxide as the active component; beta-type silicon-aluminum molecular sieve material as the auxiliary agent; titanium-tungsten-silicon composite oxide as the loading material. At the same time, silicon oxide is used as a binder to enhance the adhesion between the catalytic coating and the carrier.

[0029] The content of each component in the catalytic coating is calculated by mass ratio as active component: auxiliary agent: supporting material is 1:3:15. Among them, the mass ratio of each component in the active component is vanadium pentoxide...

Embodiment 2

[0037] The catalyst uses 300-mesh cordierite honeycomb ceramics as the carrier, and the size is 1 piece of cylinder with diameter 190.5mm*height 101.6mm (front stage) + 1 piece of cylinder with diameter 190.5mm*height 152.4mm (second stage), with a total volume of 7.22L . A catalytic coating is coated on the surface of the channel of the cordierite honeycomb ceramic carrier. The catalytic coating uses vanadium-cerium-manganese composite oxide as the active component; beta-type silicon-aluminum molecular sieve material as the auxiliary agent; titanium-tungsten-silicon composite oxide as the loading material. At the same time, silicon oxide is used as a binder to enhance the adhesion between the catalytic coating and the carrier.

[0038] The content of each component in the catalytic coating is calculated by mass ratio as active component: auxiliary agent: supporting material is 2:2:15. Among them, the mass ratio of each component in the active component is vanadium pentoxide...

Embodiment 3

[0046] The catalyst uses 300-mesh cordierite honeycomb ceramics as the carrier, and the size is 1 piece of cylinder with diameter 190.5mm*height 101.6mm (front stage) + 1 piece of cylinder with diameter 190.5mm*height 152.4mm (second stage), with a total volume of 7.22L . A catalytic coating is coated on the surface of the channel of the cordierite honeycomb ceramic carrier. The catalytic coating uses vanadium-cerium-manganese composite oxide as the active component; beta-type silicon-aluminum molecular sieve material as the auxiliary agent; titanium-tungsten-silicon composite oxide as the loading material. At the same time, silicon oxide is used as a binder to enhance the adhesion between the catalytic coating and the carrier.

[0047] The content of each component in the catalytic coating is calculated by mass ratio as active component: auxiliary agent: supporting material is 3:1:15. Among them, the mass ratio of each component in the active component is vanadium pentoxide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com