Method for preparing mono-dispersed N-doped ordered mesoporous carbon spheres with particle size of 100-800 nm at high yield in single-pass mode

A monodisperse, nitrogen-doped technology, applied in the preparation/purification of carbon, nanotechnology for materials and surface science, nanotechnology, etc., can solve problems such as unfavorable large-scale production, complex synthesis steps, low single yield, etc. problems, to achieve the effect of saving solvent consumption, simple and easy preparation method, and good monodispersity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

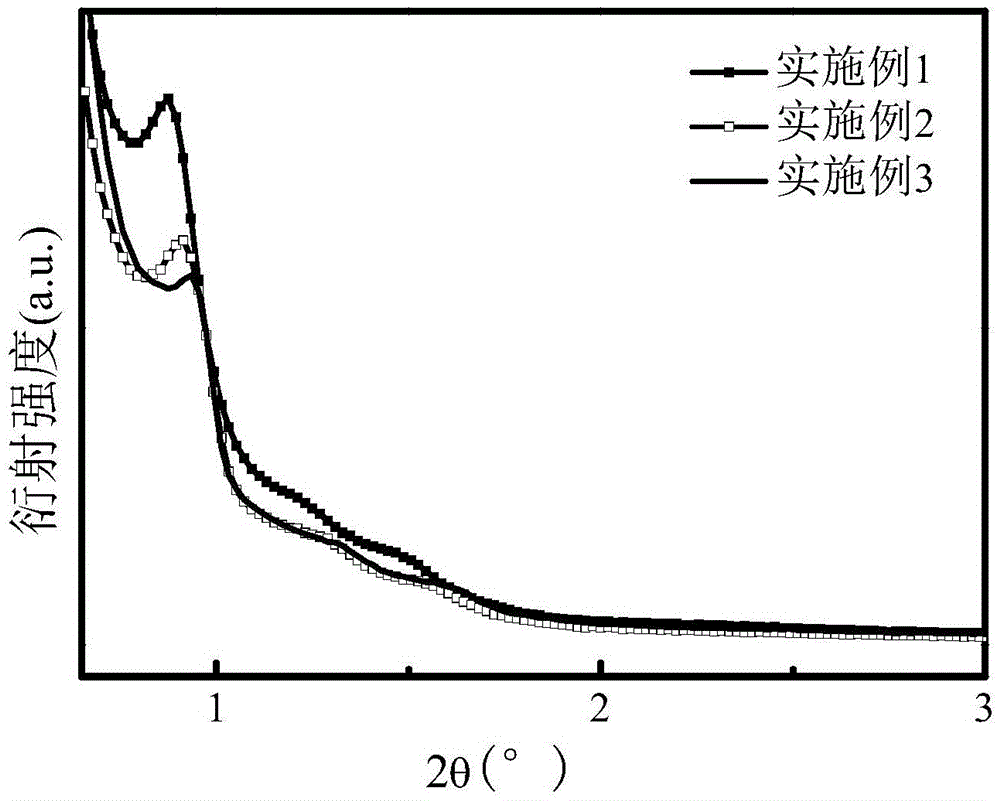

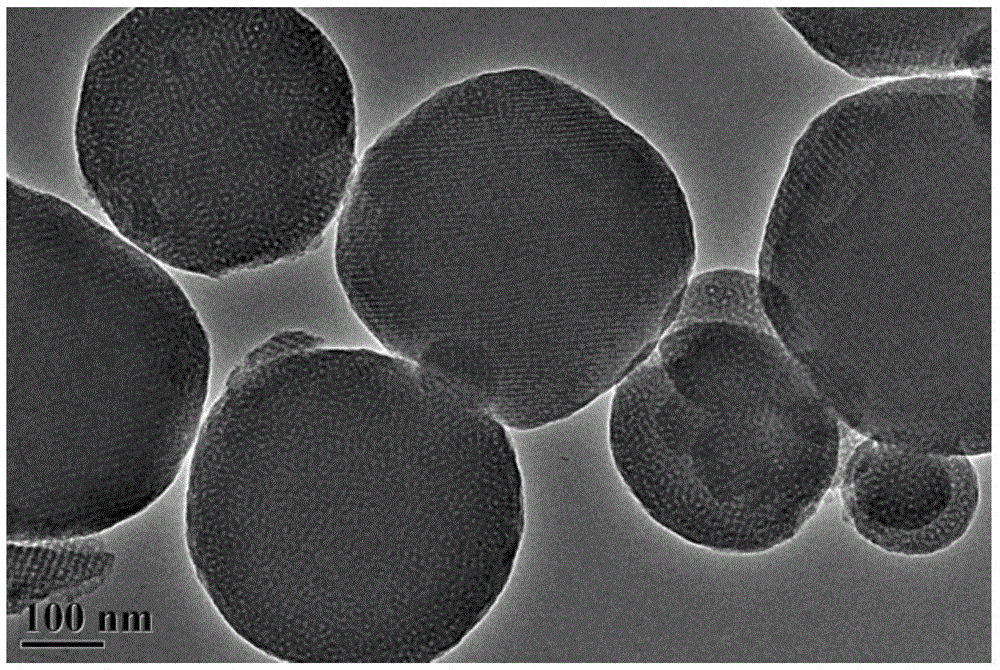

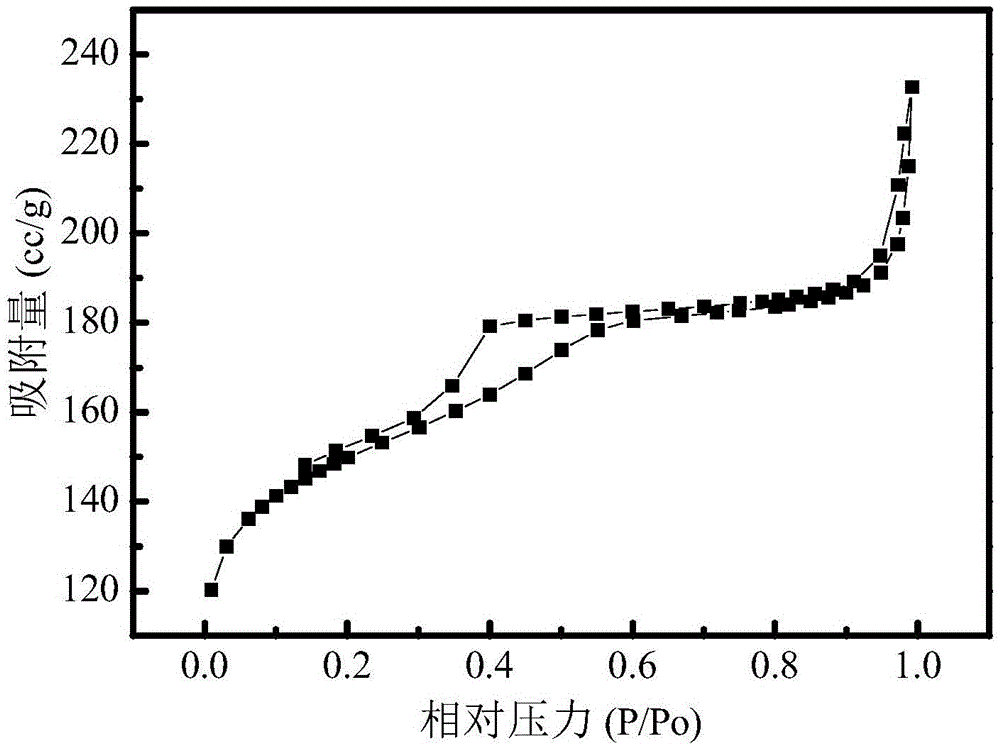

[0027] Add F127 in the mixed solution of 416mL water and 104mL dehydrated alcohol, stir until F127 dissolves completely, the concentration of F127 in the gained solution is 4.6mmol / L; Add 16.70g (150mmol) 3-aminophenol, 10.62 g (75mmol) hexamethylenetetramine and 7.43mL (192.40mmol) ammonia water (mass fraction is 27%), the control stirring speed is 1080 rev / min, after stirring at room temperature for 60 minutes, 72 ℃ of stirring reaction 24 hours, the reaction The product was separated by centrifugation, washed three times with deionized water and absolute ethanol successively, and the obtained solid was dried at 60°C for 10 hours, and then dried under N 2 Under the atmosphere, the temperature was raised to 350°C, kept for 1 hour, and then the temperature was raised to 600°C for carbonization for 3 hours, and ground to obtain 6.5g of monodisperse nitrogen-doped ordered mesoporous carbon spheres with a particle size distribution of 100-400nm.

[0028] The obtained product adop...

Embodiment 2

[0037] Add F127 to the mixed solution of 416mL water and 104mL absolute ethanol, stir until F127 dissolves completely, the concentration of F127 in the gained solution is 4.6mmol / L; Then add 22.27g (200mmol) 3-aminophenol, 14.16 g (100mmol) hexamethylenetetramine and 7.43mL (192.40mmol) ammonia water (mass fraction is 27%), the control stirring speed is 1080 rpm, after stirring at room temperature for 60 minutes, 72 ℃ stirring reaction for 24 hours, the reaction The product was separated by centrifugation, washed three times with deionized water and absolute ethanol successively, and the obtained solid was dried at 60°C for 10 hours, and then dried under N 2 Under the atmosphere, the temperature was raised to 350°C, kept for 1 hour, then heated to 600°C for carbonization for 3 hours, and ground to obtain 10.5g of monodisperse nitrogen-doped ordered mesoporous carbon spheres with a particle size distribution of 100-800nm (see Figure 8 ).

Embodiment 3

[0039] Add F127 to the mixed solution of 416mL water and 104mL absolute ethanol, stir until F127 dissolves completely, the concentration of F127 in the gained solution is 4.6mmol / L; Then add 33.41g (300mmol) 3-aminophenol, 21.24 g (150mmol) hexamethylenetetramine and 7.43mL (192.40mmol) ammonia water (mass fraction is 27%), the control stirring speed is 1080 rev / min, after stirring at room temperature for 60 minutes, 72 ℃ stirring reaction for 24 hours, the reaction The product was separated by centrifugation, washed three times with deionized water and absolute ethanol successively, and the obtained solid was dried at 60°C for 10 hours, and then dried under N 2 Under the atmosphere, the temperature was raised to 350°C, kept for 1 hour, then heated to 600°C for carbonization for 3 hours, and ground to obtain 20.0g of monodisperse nitrogen-doped ordered mesoporous carbon spheres with a particle size distribution of 100-800nm (see Figure 9 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com