A kind of ge-sn-s chalcogenide glass and preparation method thereof

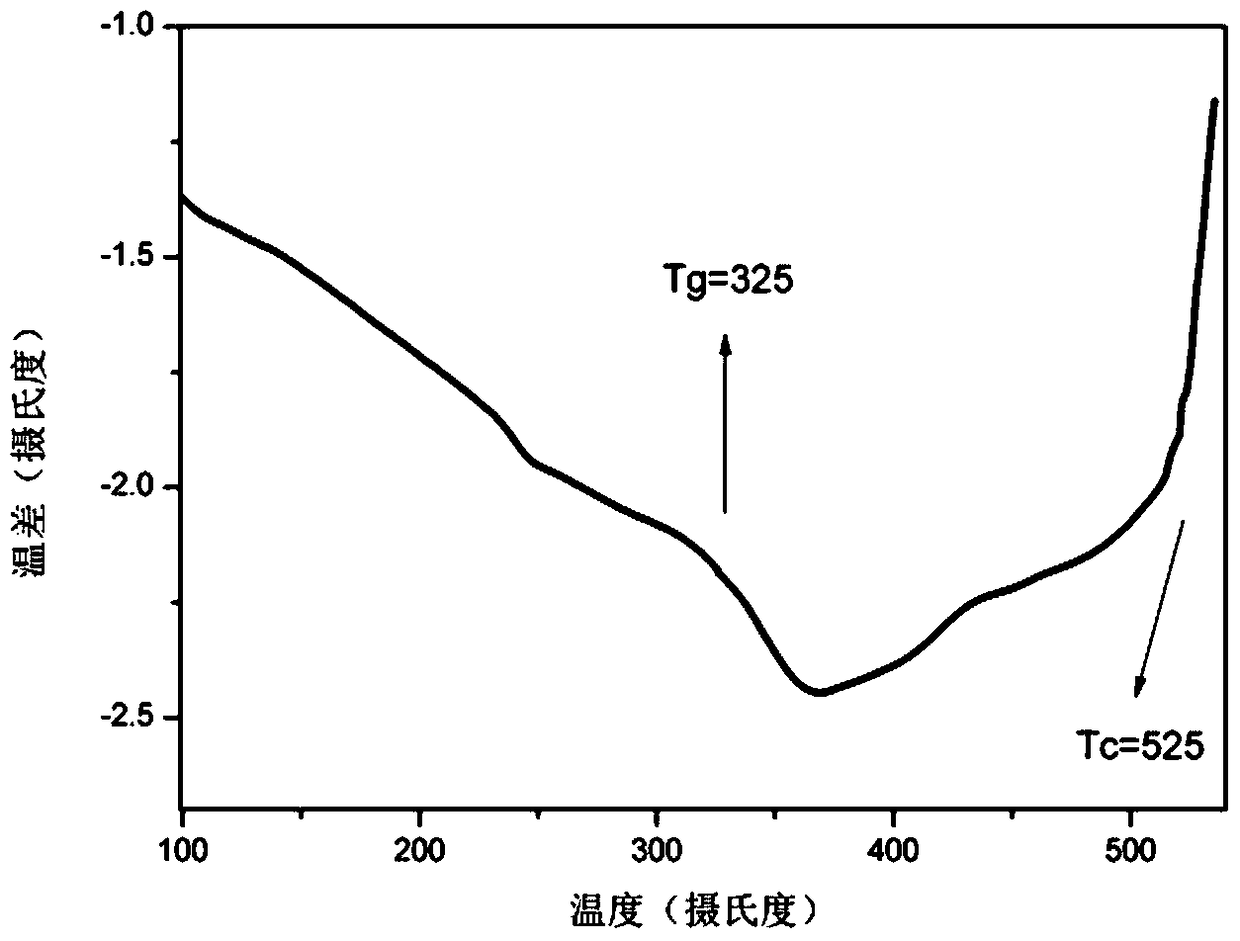

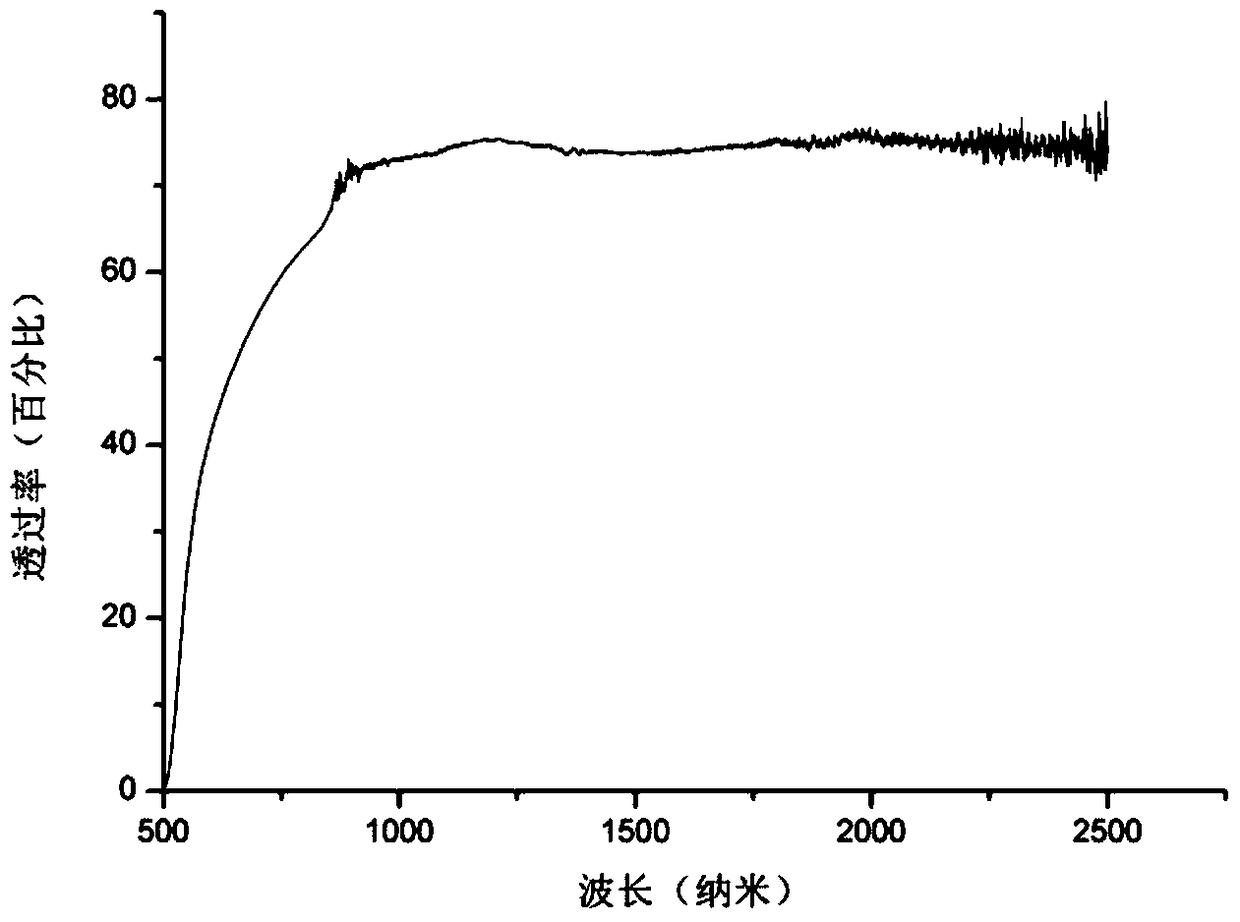

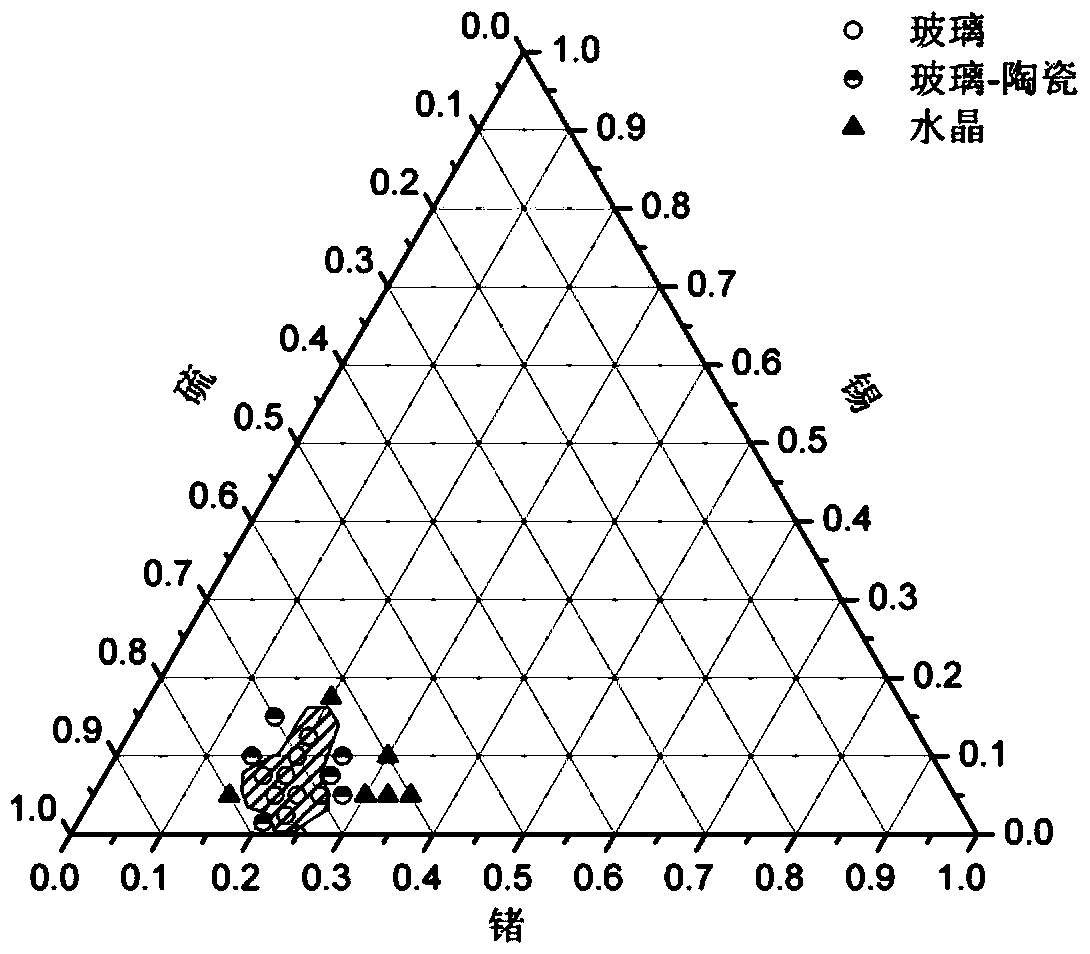

A technology of chalcogenide glass and ge-sn-s, which is applied in the field of chalcogenide glass, can solve the problems that have not been systematically studied, and achieve good mid- and far-infrared transmittance, good near-infrared transmittance, thermal performance and Good physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The composition formula of the Ge-Sn-S chalcogenide glass of Example 1 is Ge 20 sn 5 S 75 , the preparation process is as follows: use elemental germanium, elemental tin and elemental sulfur with a purity of more than 99.999%, weigh them according to the proportion and mix them uniformly, then put the mixed raw materials into a quartz tube, and evacuate to 10 -6 Pa, and then package the raw material in a sealed quartz tube; put the quartz tube packaged with the raw material into a heating furnace for high-temperature melting, the heating temperature is 850°C, and the heating time is 25h, and the quartz tube is continuously melted at the same time. Shake, after heating, get the melt in the quartz tube, then immerse the quartz tube in distilled water at 10°C to quench the encapsulated melt, take it out immediately after the wall is removed, and get Ge-Sn-S chalcogenide glass in the quartz tube The semi-finished product of Ge-Sn-S chalcogenide glass is annealed together ...

Embodiment 2

[0021] The compositional formula of the Ge-Sn-S chalcogenide glass of Example 2 is Ge 20 sn 10 S 70 , the preparation process is as follows: use elemental germanium, elemental tin and elemental sulfur with a purity of more than 99.999%, weigh them according to the proportion and mix them uniformly, then put the mixed raw materials into a quartz tube, and evacuate to 10 -4 Pa, then package the raw material in a sealed quartz tube; put the quartz tube packaged with the raw material into a heating furnace for high-temperature melting, the heating temperature is 890 ° C, the heating time is 18 hours, and the quartz tube is continuously melted at the same time. Shake, after heating, get the melt in the quartz tube, then immerse the quartz tube in distilled water at 25°C to quench the encapsulated melt, take it out immediately after the wall is removed, and get Ge-Sn-S chalcogenide glass in the quartz tube The semi-finished product of Ge-Sn-S chalcogenide glass is annealed togethe...

Embodiment 3

[0022] The composition formula of the Ge-Sn-S chalcogenide glass of Example 3 is Ge 22.5 sn 2.5 S 75, the preparation process is as follows: use elemental germanium, elemental tin and elemental sulfur with a purity of more than 99.999%, weigh them according to the proportion and mix them uniformly, then put the mixed raw materials into a quartz tube, and evacuate to 10 -6 Pa, then package the raw material in a sealed quartz tube; put the quartz tube packaged with the raw material into a heating furnace for high-temperature melting, the heating temperature is 860 ° C, and the heating time is 24 hours, and the quartz tube is continuously melted at the same time. Shake, after heating, get the melt in the quartz tube, then immerse the quartz tube in distilled water at 5°C to quench the encapsulated melt, take it out immediately after the wall is removed, and get Ge-Sn-S chalcogenide glass in the quartz tube The semi-finished product of Ge-Sn-S chalcogenide glass is annealed toge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com