Method for reducing generation of nitrophenol in preparation process of nitroanisole

A technology of nitroanisole and nitrophenol, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of shortening reaction time, increasing the difficulty of wastewater treatment, reducing three wastes and improving selection performance, cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

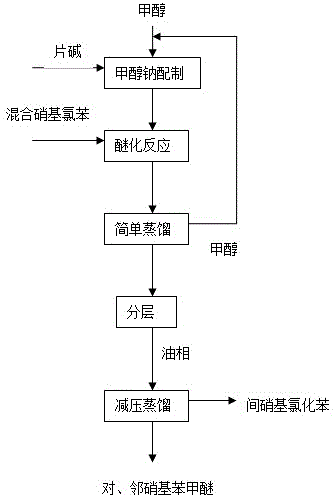

Image

Examples

Embodiment 1

[0024] 1. Sodium methoxide preparation process

[0025] Add 22 grams of flaky caustic soda and 240 milliliters of methanol into the sodium methoxide preparation pot, stir evenly, the temperature of the preparation pot rises naturally, stir when the temperature no longer rises, react for 0.5 to 2 hours, and then cool down.

[0026] 2. Nitrochlorophenyl etherification process

[0027] Add 116 grams of meta-oil and sodium methoxide solution in a methanol preparation pot to a stainless steel autoclave, control the pressure at 0.5-0.6 MPa, and control the temperature at 70-150°C, react for 2-3 hours, then keep warm for about 2 hours, and pass through distillation , washing to obtain the mixture of m-nitrochlorobenzene, o-nitroanisole and p-nitroanisole.

Embodiment 2

[0029] Below in conjunction with specific embodiment (comparative example) the present invention is described in detail:

[0030] Add 116 grams of meta-oil, 22 grams of flaky caustic soda and 240 milliliters of methanol into a stainless steel autoclave, stir to raise the temperature, control the pressure at 0.5-0.6 MPa, and control the temperature at 70-150 ° C, react for 2-3 hours, and then keep warm After about 2 hours, a mixture of m-nitroanisole, o-nitroanisole and p-nitroanisole was obtained by distillation and washing.

[0031] Conclusion: adopt the content of nitrophenol in the nitroanisole produced by the present invention to be below 200ppm, and the content of nitrophenol in the nitroanisole produced in embodiment 2 is as high as 0.1-0.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com