Pre-separating and high-purity three-outlet extracting method

An extraction method and three-outlet technology, applied in the field of solvent extraction and separation of rare earth technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] After the rare earth chloride solution of Baotou light rare earth mine is grouped by Nd / Sm, the outlet water phase La-Nd mixed rare earth is the raw material of this example, and the rare earth concentration of the rare earth chloride feed solution is 1.5mol L -1 , pH﹦2~3, the rare earth distribution is as follows:

[0029] element La 2 o 3 CeO 2 PR 6 o 11 Nd 2 o 3 SM 2 o 3 W% 26.3 52.1 6.8 14.8 ﹤0.01

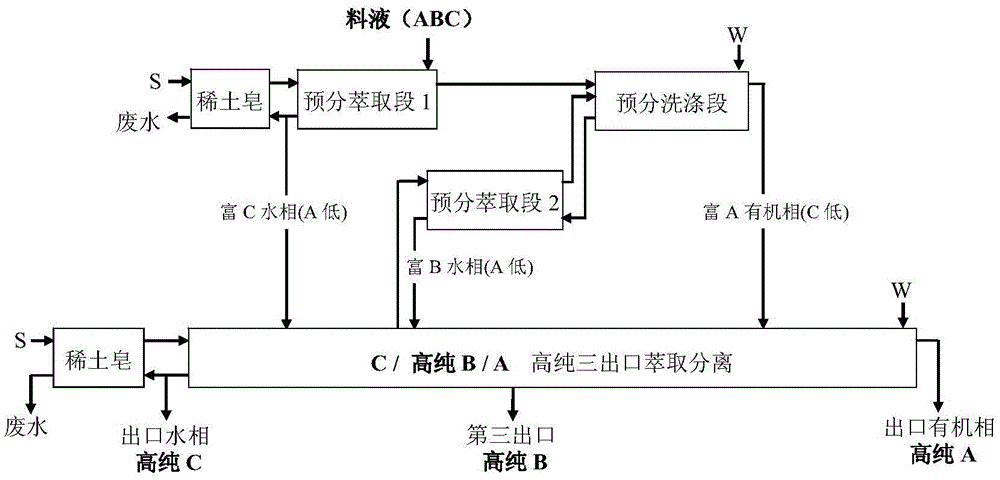

[0030] The organic phase is extracted by the extractant P 507 (2-ethylhexyl phosphate mono-2-ethylhexyl ester) and diluent kerosene, P in the organic phase 507 The concentration is 1.5mol L -1 , P 507 Saponification concentration is 0.56mol L -1 . With a kind of pre-separation high-purity three-outlet extraction method of the present invention, described embodiment 1——use the pre-separation high-purity three-outlet extraction method to separate the La-Nd mixed rare earths of light rare earth ore, and carry out extraction...

Embodiment 2

[0035] Sichuan bastnaesite was grouped by Nd / Sm to obtain La-Nd mixed rare earth chloride solution, which was used as the raw material of this example, and its rare earth concentration was 1.4mol L -1 , pH﹦2~3, the rare earth distribution is as follows:

[0036] element La 2 o 3 CeO 2 PR 6 o 11 Nd 2 o 3 SM 2 o 3 W% 40.52 46.83 3.56 9.09 ﹤0.01

[0037] The organic phase is extracted by the extractant P 507 (2-ethylhexyl phosphate mono-2-ethylhexyl ester) and diluent kerosene, P in the organic phase 507 The concentration is 1.5mol L -1 , P 507 The saponification concentration is 0.54mol L -1 . With a kind of pre-separation high-purity three-outlet extraction method of the present invention, described embodiment 1——use the pre-separation high-purity three-outlet extraction method to separate the La-Nd mixed rare earths of light rare earth ore, and carry out extraction and separation. The process flow used is shown in the appendix...

Embodiment 3

[0042] The GdTbDy enrichment produced from low yttrium ion adsorption type rare earth ore is used as raw material, and the rare earth concentration of the rare earth chloride solution is 1.2mol L -1 , pH≈3, the rare earth distribution is as follows:

[0043] element Gd 2 o 3 Tb 4 o 7 Dy 2 o 3 Ho 2 o 3 ∑ W% 40.9 12.8 46 0.26 99.96

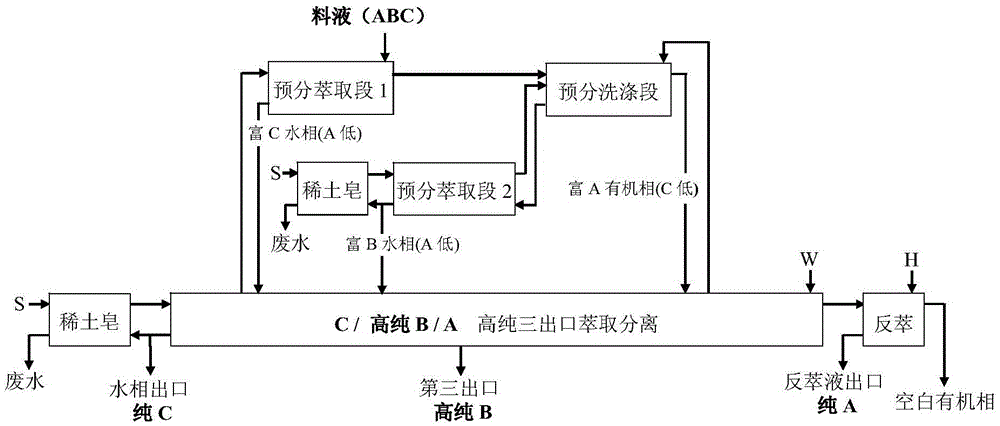

[0044] The organic phase is extracted by the extractant P 507 (2-ethylhexyl phosphate mono-2-ethylhexyl ester) and diluent kerosene, P in the organic phase 507 The concentration is 1.5mol L -1 , P 507 Saponification concentration is 0.56mol L -1 . With a kind of pre-separation high-purity three-outlet extraction method of the present invention, described embodiment 2---separate GdTbDy enrichment by pre-separation high-purity three-outlet extraction method, carry out extraction and separation, and the process flow used is shown in the appendix figure 2 shown. Due to the Tb in the GdTbDy enrichment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com