Ultrasonic-assisted electrostatic spinning apparatus

An ultrasonic and electrospinning technology, applied in textiles and papermaking, filament/thread forming, feeding solution to spinnerets, etc., can solve problems such as reducing the viscosity of electrospinning solution and melt, reducing fiber diameter, etc., to achieve The effect of expanding the concentration range of electrospinning, increasing crystallinity, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

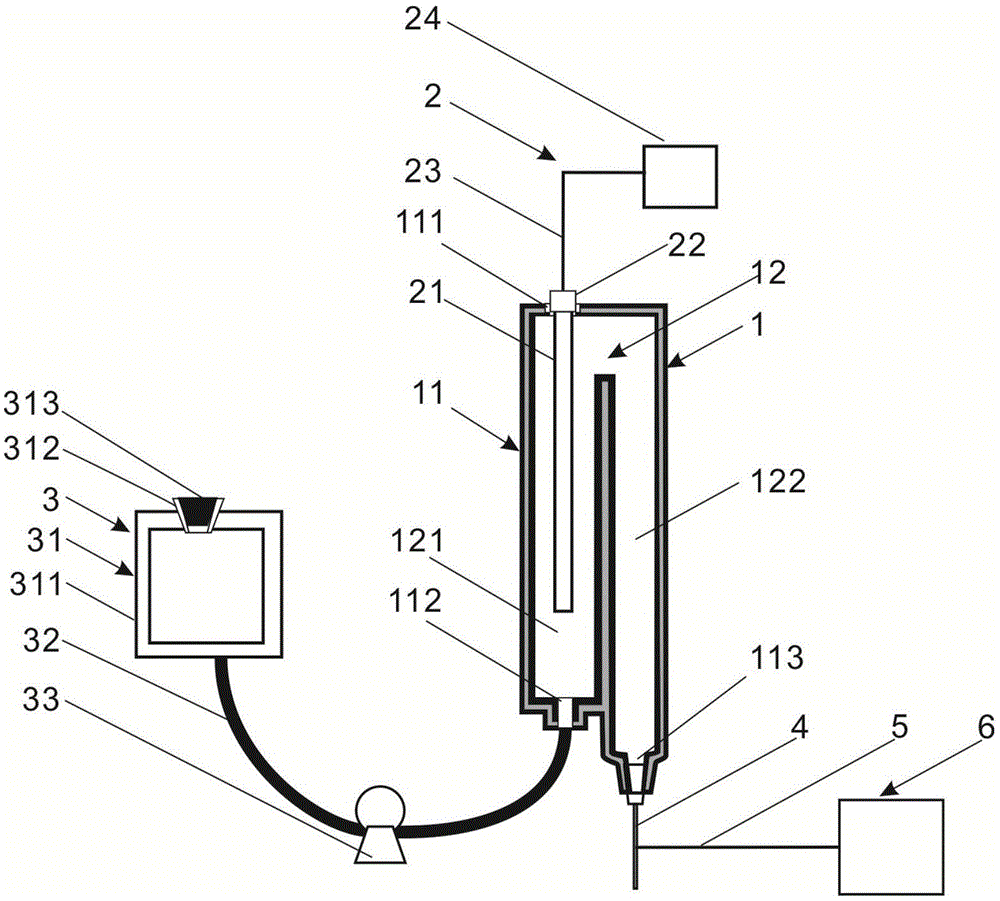

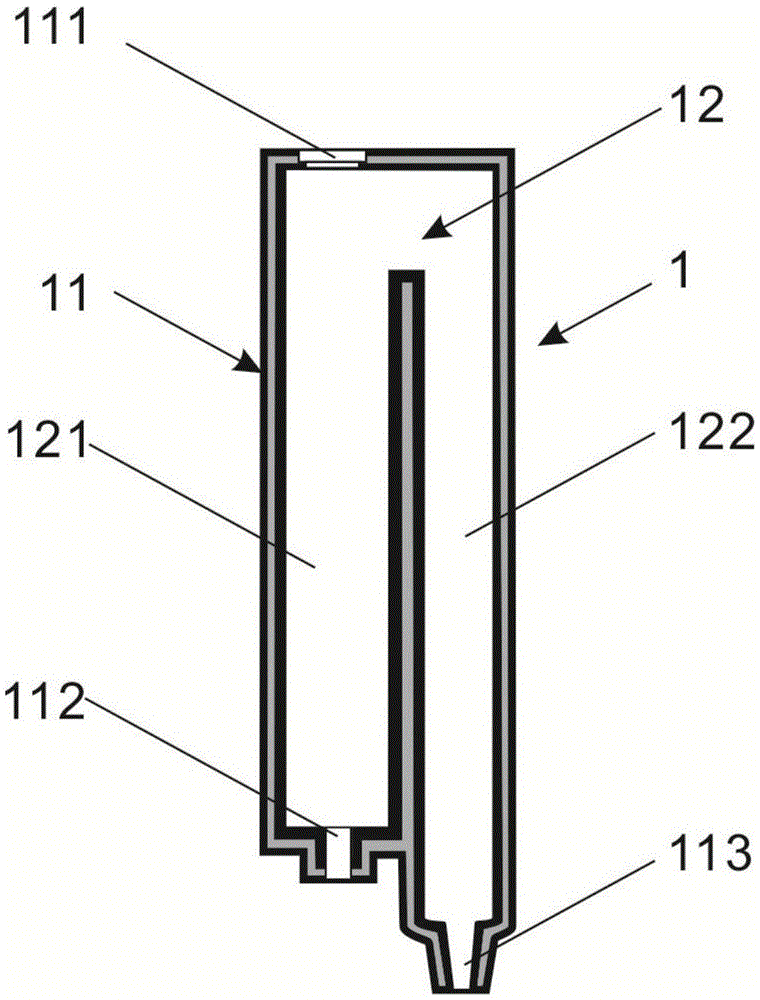

[0027] exist figure 1 In the process, the spinning solution is added into the casing (311) of the liquid storage tank (31) through the feeding port (312) on the upper part of the liquid storage tank (31) of the liquid supply device (3), and then in the liquid supply pump (33) Under the action of the liquid supply pipe (32), it is pumped into the machine cavity of the spinning machine main body (1) from the box body (311) through the liquid supply port (112) at the bottom of the main body (11) of the spinning machine main body (1). (12) vibrating cavity (121); probe into the machine chamber (12) of spinning machine main body (1) from the ultrasonic vibrating device probe (111) on the main body (11) top of spinning machine main body (1) The horn (21) of the ultrasonic vibrating device (2) of the vibrating chamber (121) and the transducer (22) connected to it start to vibrate under the control of the ultrasonic controller (24) connected to it by the cable (23). The spinning solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com