Titanium-based composite armor and manufacturing method thereof

A technology of titanium-based composite materials and manufacturing methods, applied in the direction of armor, armor plate structure, chemical instruments and methods, etc., can solve problems such as insufficient toughness, decreased ability of armor materials to resist multiple bullets, and inability to prepare armor layers with complex structures , to achieve the effect of improving the anti-ballistic effect and improving the ability to resist multiple strikes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment provides a titanium-based composite material armor, which includes an upper layer, a middle layer and a lower layer, wherein the upper layer and the lower layer are titanium alloy layers, the middle layer is a titanium alloy and ceramic composite material layer, and the middle layer has a titanium alloy layer Space lattice structure, the titanium alloy space lattice structure divides the titanium alloy and ceramic composite material layer into multiple unit modules; the space lattice structure is an X-shaped space lattice structure, the thickness of the upper layer is 5mm, and the middle layer The thickness of the upper layer is 15mm, and the thickness of the lower layer is 5mm. The structural schematic diagram of the titanium matrix composite armor is as follows: figure 2 shown.

[0039] The manufacturing method of the titanium-based composite armor is as described above, wherein the specific method of electron beam selective melting is as follows: af...

Embodiment 2

[0041] This embodiment provides a titanium-based composite material armor, which includes an upper layer, a middle layer and a lower layer, wherein the upper layer and the lower layer are titanium alloy layers, the middle layer is a titanium alloy and ceramic composite material layer, and the middle layer has a titanium alloy layer Space lattice structure, the titanium alloy space lattice structure divides the titanium alloy and ceramic composite material layer into multiple unit modules; the space lattice structure is a pyramid-shaped space lattice structure, the thickness of the upper layer is 1mm, and the middle layer The thickness of the upper layer is 10mm, and the thickness of the lower layer is 1mm.

[0042] The manufacturing method of the titanium-based composite material armor is basically the same as that of Example 1, except that the ceramic powder is made of B 4 C powder, its mass content is 30% (based on the total mass of the mixture of titanium alloy powder and c...

Embodiment 3

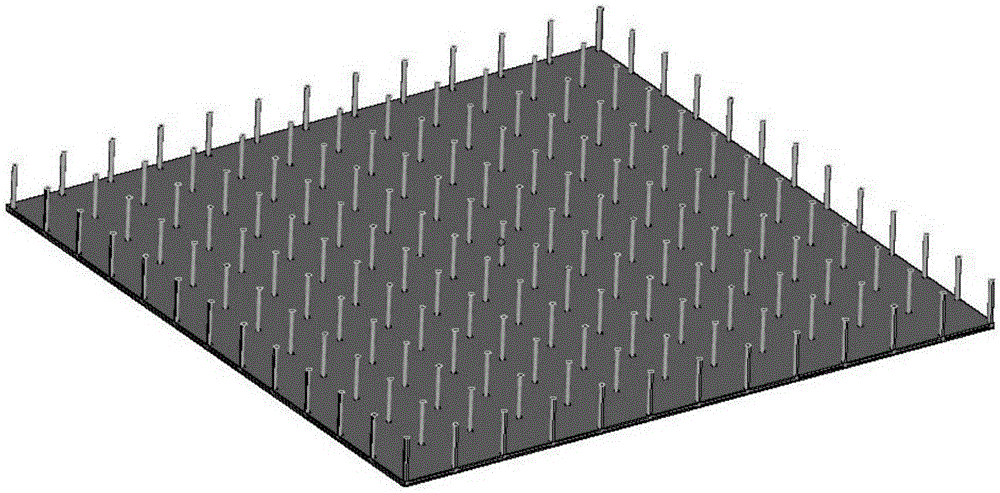

[0044] This embodiment provides a titanium-based composite material armor, which includes an upper layer, a middle layer and a lower layer, wherein the upper layer and the lower layer are titanium alloy layers, the middle layer is a titanium alloy and ceramic composite material layer, and the middle layer has a titanium alloy layer Space lattice structure, the titanium alloy space lattice structure divides the titanium alloy and ceramic composite material layer into multiple unit modules; the space lattice structure is a tetrahedral space lattice structure, the thickness of the upper layer is 10mm, and the middle layer The thickness of the upper layer is 20mm, and the thickness of the lower layer is 10mm.

[0045] The manufacturing method of the titanium-based composite material armor is basically the same as that of Example 1, except that the ceramic powder is made of B 4 C powder, its mass content is 30% (based on the total mass of the mixture of titanium alloy powder and ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com