Gas chromatographic detection system and method for analyzing hydrogen isotopes and trace impurity components in He

A hydrogen isotope and detection system technology, applied in the field of gas chromatography analysis, can solve the problems of long time, difficult hydrogen isotope separation and online quantitative measurement, and achieve the effect of convenient operation and meeting the analysis requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0105] This embodiment is used to illustrate the method of analyzing trace impurity gases in helium using a DID detector.

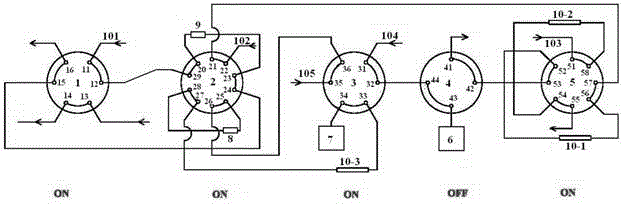

[0106] Use the method described above to purge the entire gas circuit system with each carrier gas (combined with Figure 1). After the output pressure of the sample gas is stable, go through steps a1-a2-a3 of the method described above (combined with figure 2 , 3 ) and steps b1-b2-b3 (combining figure 2 , 4 ), adjust the different states of each valve to achieve the purpose of sample loading, sample injection, analysis and detection respectively.

[0107] The He carrier gas flow rate is 15mL / min, the sample gas He contains about 1.0ppm impurity gas components, the selected capacity of the quantitative tube II9 in the step a1 is 0.5mL, and the first chromatographic separation column 10-1 adopted in the step a3 is 15m× 0.53mm×50μm molecular sieve capillary column (MS), the second chromatographic separation column 10-2 used in step b3 is a 15m×0.53mm×40μm...

Embodiment 2

[0110] This embodiment is used to illustrate the method of analyzing trace amounts of hydrogen isotope gas in helium using a DID detector.

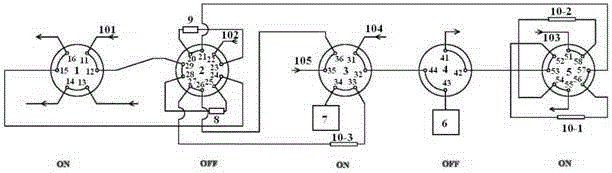

[0111] Use the method described above to purge the entire gas circuit system with various carrier gases (combined with Figure 1). After the output pressure of the sample gas is stable, go through steps c1-c2-c3 of the method described above (combined with Figure 5 , 6 ), adjust the different states of each valve to achieve the purpose of sample loading, sample injection, analysis and detection respectively.

[0112] The carrier gas flow rate is 9.0mL / min, the content of trace hydrogen and deuterium components in the sample gas He is about 1000ppm, the selected capacity of quantitative tube I8 in step c1 is 0.25mL, and the third chromatographic separation column 10-3 used in step c3 At the temperature of liquid nitrogen, it is a 0.6×3.0mm alumina-manganese chloride coated modified packed column. Under this condition, H 2 -HD components ...

Embodiment 3

[0115] This example is used to illustrate the method of analyzing the percentage content of hydrogen isotope gas in helium by TCD.

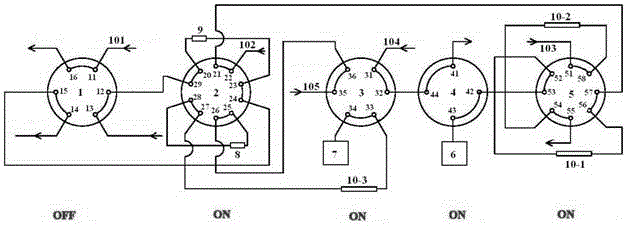

[0116] Use the method described above to purge the entire gas circuit system with various carrier gases (combined with Figure 1). After the output pressure of the sample gas is stable, go through steps d1-d2-d3 of the method described above (combined with Figure 7 , 8 ), adjust the different states of each valve to achieve the purpose of sample loading, sample injection, analysis and detection respectively.

[0117] The carrier gas flow rate is 40.0mL / min, the content of hydrogen and deuterium components in the sample gas He is 8%, the selected capacity of quantitative tube I8 in step d1 is 1.0mL, and the third chromatographic separation column 10-3 adopted in step d3 At the temperature of liquid nitrogen, it is a 4m×0.53mm aluminum oxide-manganese chloride coated modified capillary column. Under this condition, H 2 -The resolution of HD compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com