Photoresist and preparation method and application thereof

A photoresist and photoinitiator technology, applied in the field of photoresist, can solve the problems of low drying speed, difficult to control product viscosity, difficult to control viscosity, etc., to achieve excellent weather resistance and corrosion resistance, reliable adhesion, curing fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

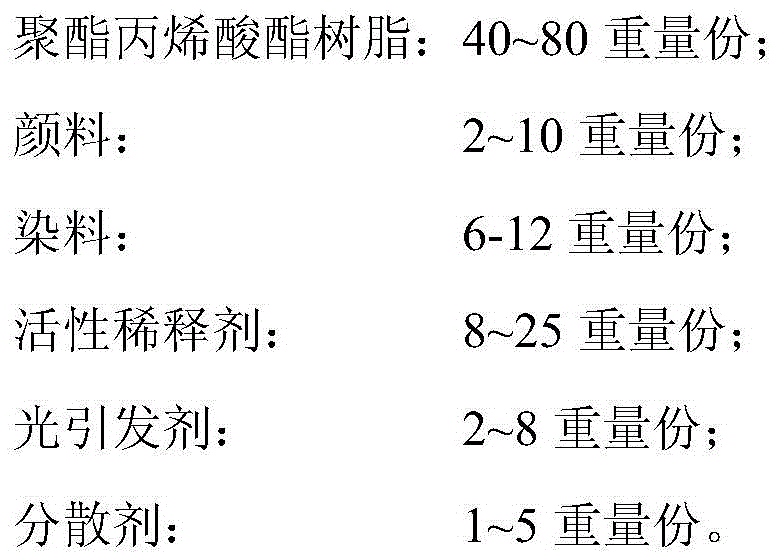

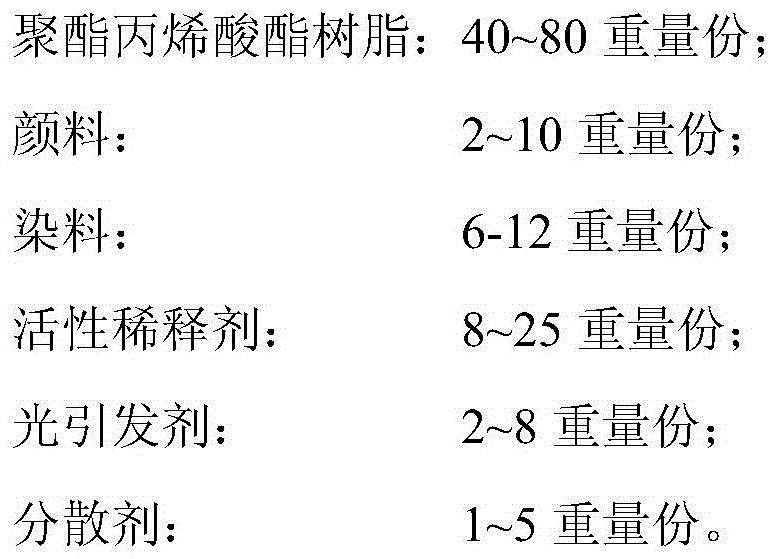

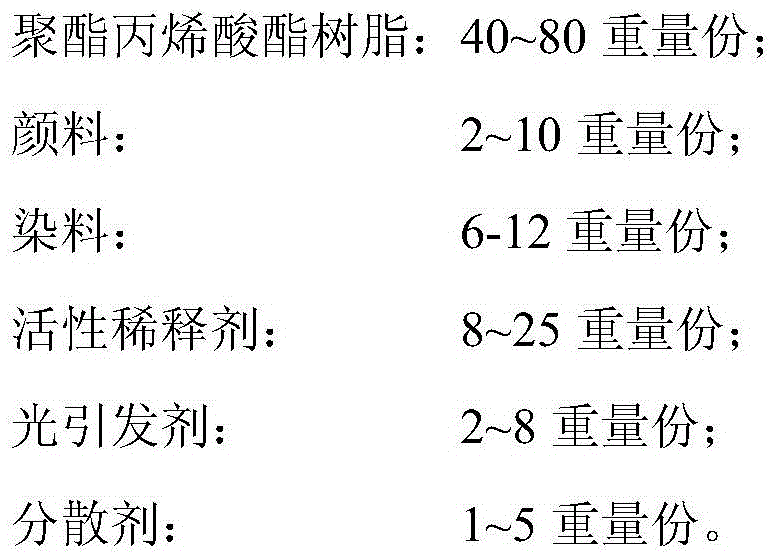

[0041] The present invention also provides a preparation method of photoresist, comprising the steps of:

[0042] 1) 2-10 parts by weight of pigment and 6-12 parts by weight of dye are mixed, mixed with 20-30 parts by weight of polyester acrylate resin, dispersed and rolled to a particle size below 1 micron, to obtain a slurry carrier.

[0043] 2) The carrier is mixed with 2-7 parts by weight of active diluent and rolled to obtain a fine slurry.

[0044] 3) Add 20-50 parts by weight polyacrylate resin, 6-18 parts by weight reactive diluent, 2-8 parts photoinitiator and 1-5 parts dispersant to the fine slurry, and filter after stirring for some time, Obtain photoresist. The stirring speed is 800-2500 rpm, the stirring time is 15-90 minutes, and the photoresist can be obtained after filtering with a 1 micron butterfly filter.

[0045] In step 3), ensure that more than 95% of the particle size of the ground pigment is less than 1 micron, which can be tracked and monitored with ...

Embodiment 1

[0050] Preparation of blue photoresist for inkjet UV-curable printing.

[0051] Disperse the mixture of 6 parts of phthalocyanine blue and 7 parts of oil-soluble dye and 15 parts of polyacrylate resin on a three-roller and grind it finely, then add 6 parts of dipentaerythritol acrylate and mix to form a slurry, then add 45 parts of polyester acrylic acid Ester resin, 30 parts of dipentaerythritol pentaacrylate, 3 parts of 1-hydroxy-cyclohexyl benzophenone, and 1 part of dispersant, the stirring speed is controlled at 1800 rpm, and the UV blue photoresist can be obtained after stirring for 90 minutes. And use a 1 micron butterfly filter to filter all the blue photoresist to get the finished product. Keep out of direct sunlight throughout the process.

Embodiment 2

[0053] Preparation of blue transparent photoresist for inkjet UV-curable printing.

[0054] Disperse the mixture of 10 parts of phthalocyanine blue and 8 parts of oil-soluble dye and 10 parts of polyacrylate resin on a three-roll machine and grind it finely, then add 4 parts of tripropylene glycol diacrylate and mix to form a slurry, then add 40 parts of polyacrylate resin Acrylate resin and 16 parts of tripropylene glycol diacrylate and 3 parts of 2-hydroxy-2-methyl-1-phenyl-1-propanone, 3 parts of benzophenone, 3 parts of dispersant, control the stirring speed at 1800 rev / min, after stirring for 90 minutes, UV blue transparent photoresist can be obtained, and the finished product can be obtained by filtering all the blue transparent photoresist with a 1 micron butterfly filter. The whole process takes place indoors.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com