MEMS (Micro Electro Mechanical System) microphone, preparation method thereof and electronic device

A microphone and backplane technology, applied in the field of MEMS microphones and their preparation, can solve the problems of low stiffness coefficient, poor frequency response performance of microphones, difficulty in preparing sensitive microphones, etc., and achieve the effects of improving sensitivity and reducing nonlinear errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] In order to solve the problems in the prior art, a MEMS microphone is provided, and the MEMS device will be further described below in conjunction with the accompanying drawings, wherein the Figure 1m It is a structural schematic diagram of the MEMS device.

[0065] The MEMS microphone of the present invention comprises:

[0066] semiconductor substrate 101;

[0067] The first backplane 103 is located on the semiconductor substrate 101;

[0068] The diaphragm 105 is located on the first backplane;

[0069] The second backplane 107 is located on the diaphragm 105;

[0070] Wherein, a first cavity is formed between the first backplane 103 and the diaphragm, and a second cavity is formed between the second backplane and the diaphragm;

[0071] A back cavity is formed in the semiconductor substrate below the first cavity.

[0072] Wherein, the semiconductor substrate 101 may be at least one of the materials mentioned below: silicon, silicon-on-insulator (SOI), silicon...

Embodiment 2

[0094] In order to solve the problems existing in the prior art, a method for preparing a MEMS microphone is provided, and the method for preparing the MEMS microphone will be further described below in conjunction with the accompanying drawings, wherein the Figure 1a-1m It is a structural schematic diagram of the MEMS microphone.

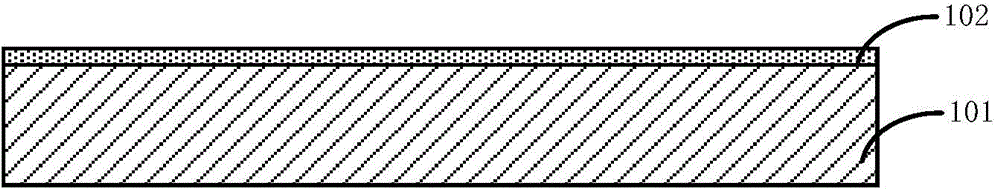

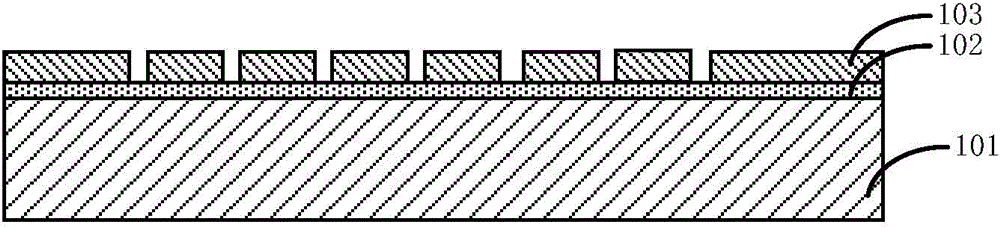

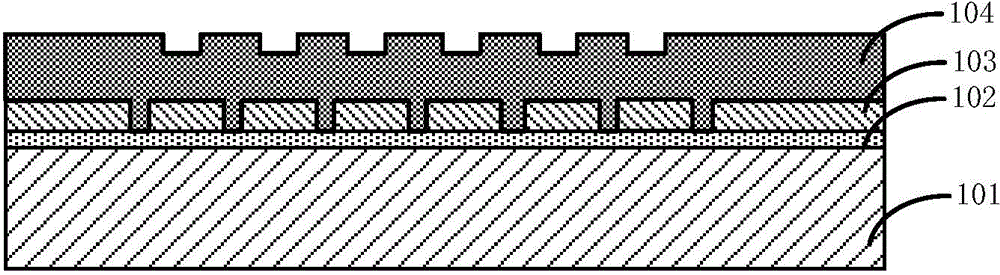

[0095] First, step 201 is performed to provide a semiconductor substrate 101 on which an insulating layer 102 and a first backplane 103 are formed.

[0096] Specifically, such as Figure 1a As shown, in this step, the semiconductor substrate may be at least one of the materials mentioned below: silicon, silicon-on-insulator (SOI), silicon-on-insulator (SSOI), silicon-germanium-on-insulator (S-SiGeOI), silicon germanium on insulator (SiGeOI) and germanium on insulator (GeOI), etc.

[0097] The insulating layer 102 can be selected from SiN, but is not limited to the material.

[0098] The first backplane can be polysilicon or SiGe.

[0099] Step ...

Embodiment 3

[0149] The present invention also provides an electronic device, including the MEMS microphone described in Embodiment 1. Wherein, the semiconductor device is the MEMS microphone described in Embodiment 1, or the MEMS microphone obtained according to the preparation method described in Embodiment 2.

[0150] The electronic device of this embodiment can be any electronic product or equipment such as mobile phone, tablet computer, notebook computer, netbook, game console, TV set, VCD, DVD, navigator, camera, video recorder, voice recorder, MP3, MP4, PSP, etc. , can also be any intermediate product including the MEMS device. The electronic device of the embodiment of the present invention has better performance due to the use of the above-mentioned MEMS device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com