A method for manufacturing fine lines in the inner layer of a printed circuit board

A printed circuit board and fine circuit technology, which is applied in the fields of printed circuit manufacturing, circuit lamination, printed circuit, etc., can solve the problem of poor bonding between substrate and conductive layer, incomplete avoidance of side erosion, long production cycle, etc. problems, to achieve the effect of solving poor bonding force, shortening production cycle, and solving side erosion problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

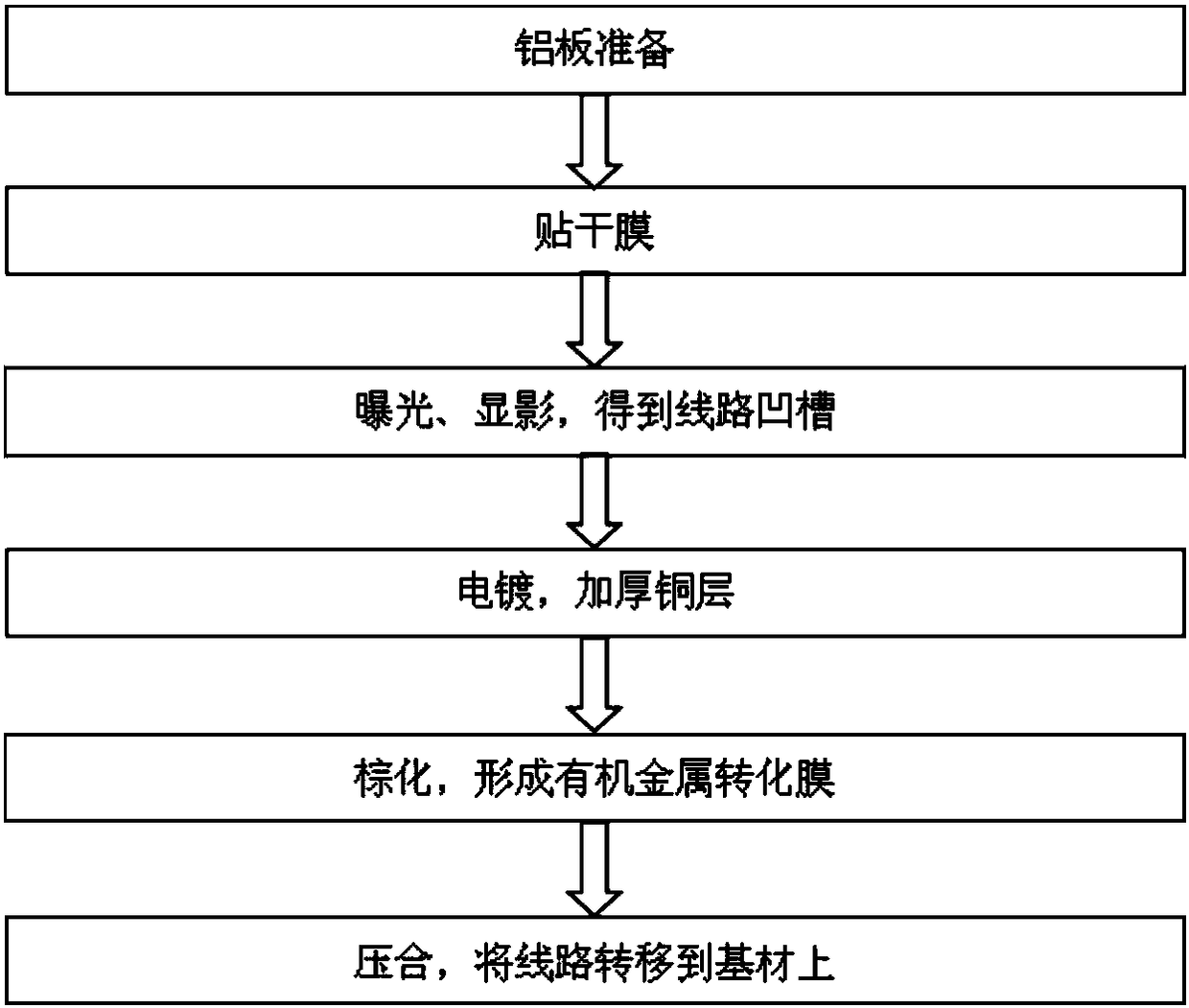

[0044] A method for manufacturing fine lines in the inner layer of a printed circuit board, comprising the steps of:

[0045] (1) Stick a layer of acid-resistant photoresist dry film with a thickness of 20 μm on the aluminum plate; before sticking the film, roughen the surface of the aluminum plate, specifically using H 2 SO 4 and H 2 o 2 The composition of the mixed solution washes the surface of the aluminum plate for 30 seconds; where H 2 SO 4 The concentration is 120g / L, H 2 o 2 The concentration is 12g / L. The roughening treatment makes the photoresist dry film and the aluminum plate tightly bonded.

[0046] (2) Use the LDI laser direct imaging exposure machine for exposure processing to obtain the conductive circuit pattern; in the exposure processing, follow the positive film process, and the unexposed part is the circuit area.

[0047] (3) developing process, the developing solution used is K 2 CO 3 solution, the K 2 CO 3 The concentration of the solution is...

Embodiment 2

[0052] A method for manufacturing fine lines in the inner layer of a printed circuit board, comprising the steps of:

[0053] (1) Stick a layer of acid-resistant photoresist dry film with a thickness of 30 μm on the aluminum plate; before sticking the film, roughen the surface of the aluminum plate, specifically using H 2 SO 4 and H 2 o 2 The composition of the mixed solution washes the surface of the aluminum plate for 180 seconds; where H 2 SO 4 The concentration is 70g / L, H 2 o 2 The concentration is 6g / L. Make the photoresist dry film and the aluminum plate tightly bonded.

[0054] (2) Use the LDI laser direct imaging exposure machine for exposure processing to obtain the conductive circuit pattern; in the exposure processing, follow the positive film process, and the unexposed part is the circuit area.

[0055] (3) developing process, the developing solution used is K 2 CO 3 solution, the K 2 CO 3 The concentration of the solution is 1.3%, and the developing t...

Embodiment 3

[0060] A method for manufacturing fine lines in the inner layer of a printed circuit board, comprising the steps of:

[0061] (1) Paste a layer of acid-resistant photoresist dry film with a thickness of 40 μm on the aluminum plate; before the film, roughen the surface of the aluminum plate, specifically using H 2 SO 4 and H 2 o 2 The composition of the mixed solution washes the surface of the aluminum plate for 100 seconds; where H 2 SO 4 The concentration is 90g / L, H 2 o 2 The concentration is 9g / L. Make the photoresist dry film and the aluminum plate tightly bonded.

[0062] (2) Use the LDI laser direct imaging exposure machine for exposure processing to obtain the conductive circuit pattern; in the exposure processing, follow the positive film process, and the unexposed part is the circuit area.

[0063] (3) developing process, the developing solution used is K 2 CO 3 solution, the K 2 CO 3 The concentration of the solution is 1%, and the developing time is 2 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com