Borosilicate optical glass and an optical element

A borosilicate and optical glass technology, applied in the field of prefabricated parts and optical components, can solve the problems of increased surface tension of molten glass, high viscosity of molten glass at high temperature, and difficulty in glass production, achieving low glass transition temperature Tg, Lower molding temperature and better chemical stability of glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

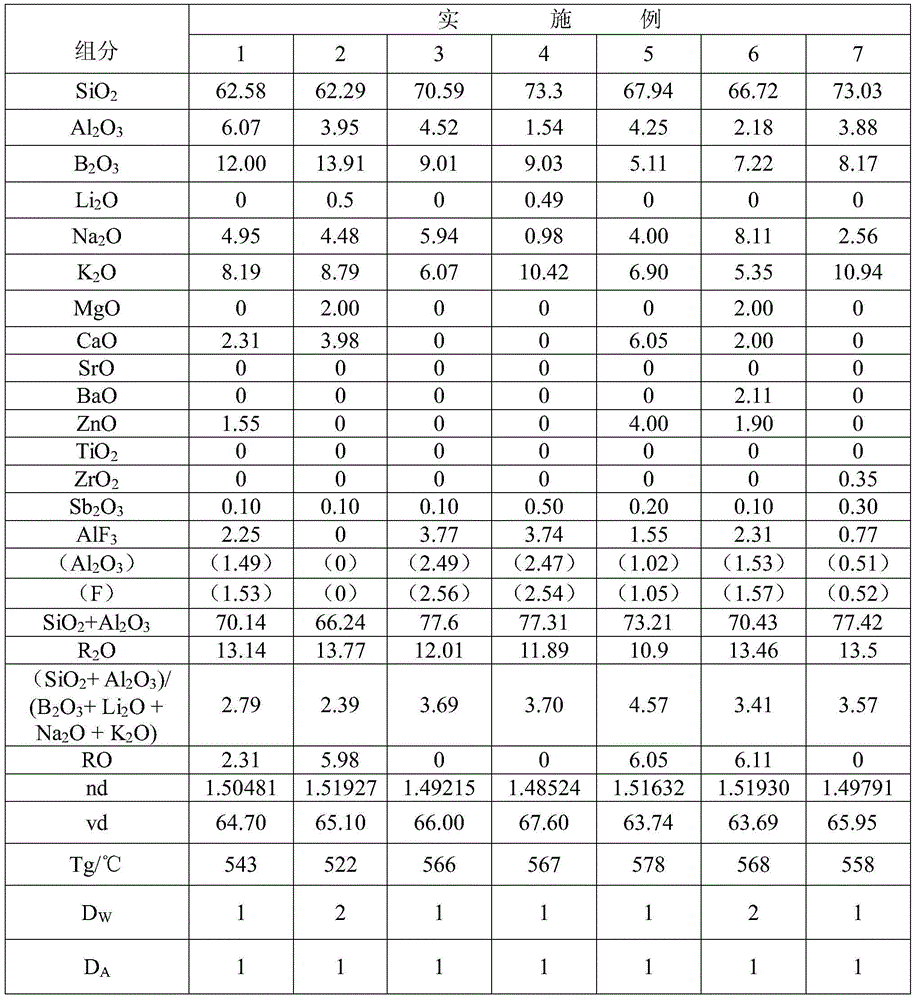

[0051] In the following content, the examples listed in the table will describe the present invention in more detail, and serve as a reference for others skilled in the art. It should be noted that the contents of the glass components in Examples 1-20 are expressed by weight percentage, and the protection scope of the present invention is not limited to the examples.

[0052] The optical glass (embodiment 1-20) shown in table 1-table 3 is by weighing according to the ratio of each embodiment shown in table 1-table 3 and mixing common raw materials (such as oxide, fluoride, hydrogen oxides, carbonates, nitrates, etc.), the mixed raw materials are placed in a platinum crucible, melted at 1260°C-1350°C for 2-5 hours, and after clarification, stirring and homogenization, no bubbles and no Homogeneous molten glass of undissolved substances, obtained by casting the molten glass in a mold and annealing it.

[0053] Table 1

[0054]

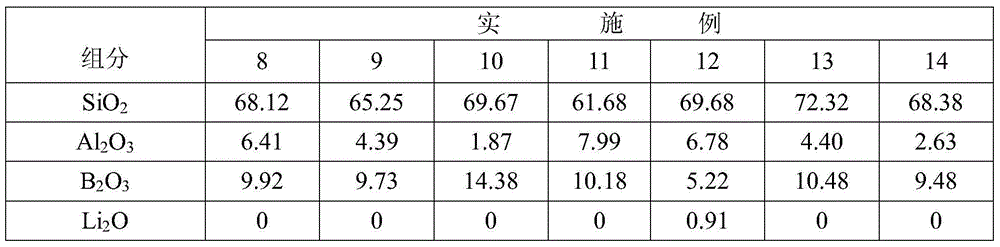

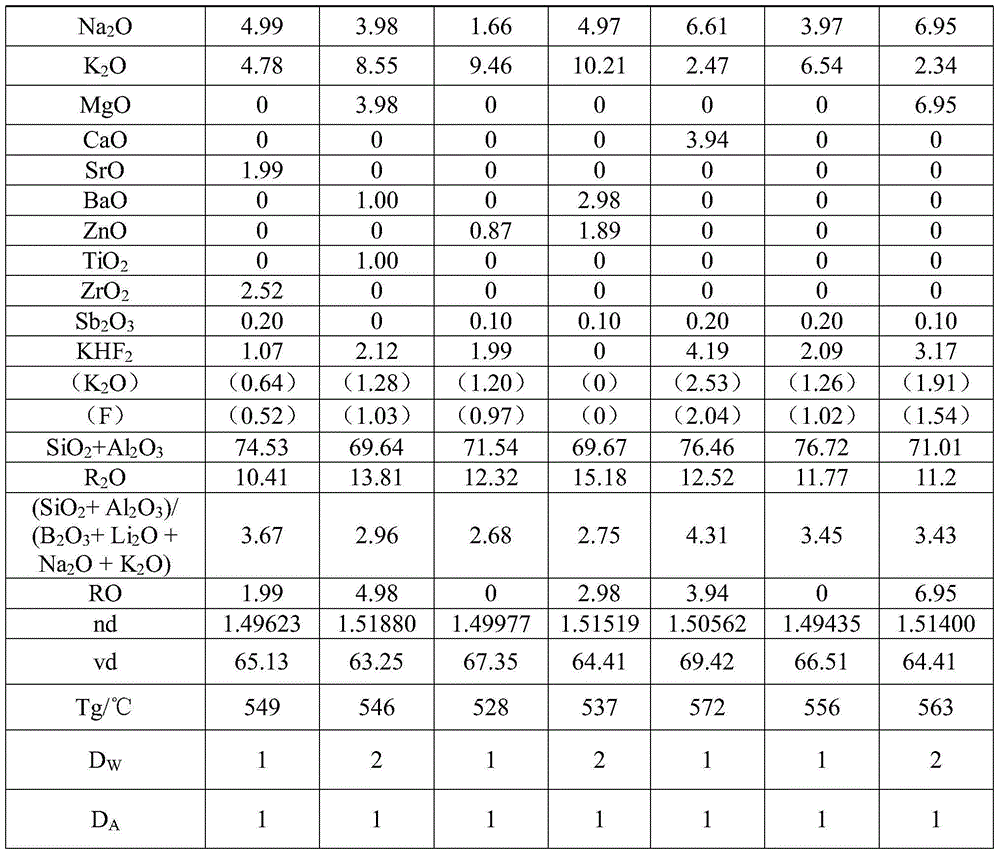

[0055] Table 2

[0056]

[0057]

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com