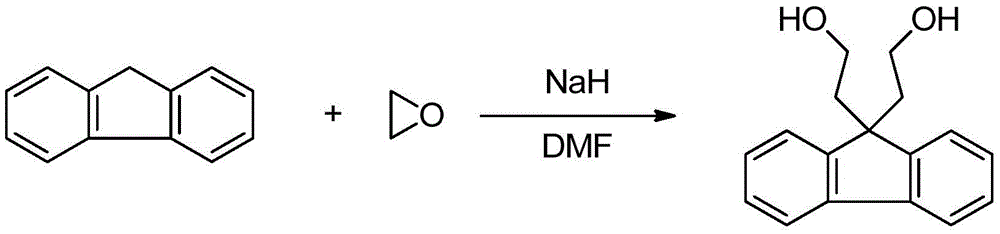

Preparation method of 9,9-fluorene diethanol

A technology of fluorene diethanol and ethylene oxide, applied in 9 fields, can solve the problems of high cost, low yield, complicated process and the like of the preparation method, and achieve the effects of remarkable technological progress, stable yield and optimized reaction temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

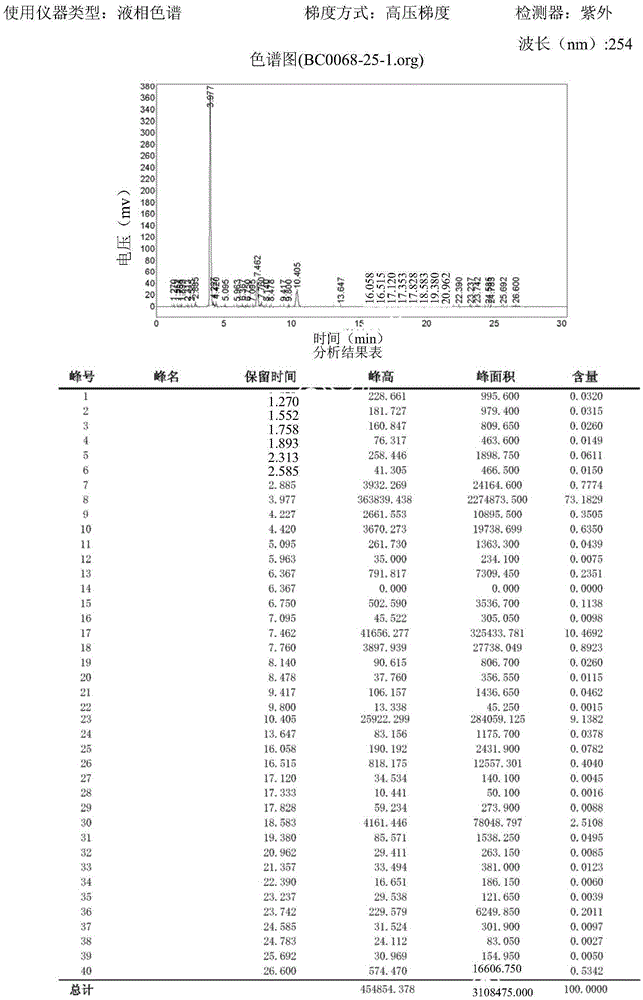

[0027] Add the raw material fluorene (100g) to N,N-dimethylformamide (750ml), under nitrogen protection, stir until the solids are completely dissolved, cool to 0°C, add sodium hydride (60g, 3-4 times, 15 minutes to complete the addition), and maintain the temperature between 0 and 5°C (a large amount of gas is released). After the addition, the temperature in the reaction bottle was kept at 0-10°C. After stirring for one hour, it was cooled to 0°C again, and then ethylene oxide (60ml) was diluted with N,N-dimethylformamide (50ml). Add it to the reaction bottle (addition is completed in one minute), after the addition, slowly rise to 15°C, and keep it warm for 5 hours (in-control 1). Post-treatment, the reaction mixture was slowly poured into 800g of ice water to quench, then extracted with EA (ethyl acetate) (800ml×3), the organic phase was combined, and the organic phase was washed once with saturated brine (800ml), and sulfuric acid was added Sodium dry. After filtering o...

Embodiment 2

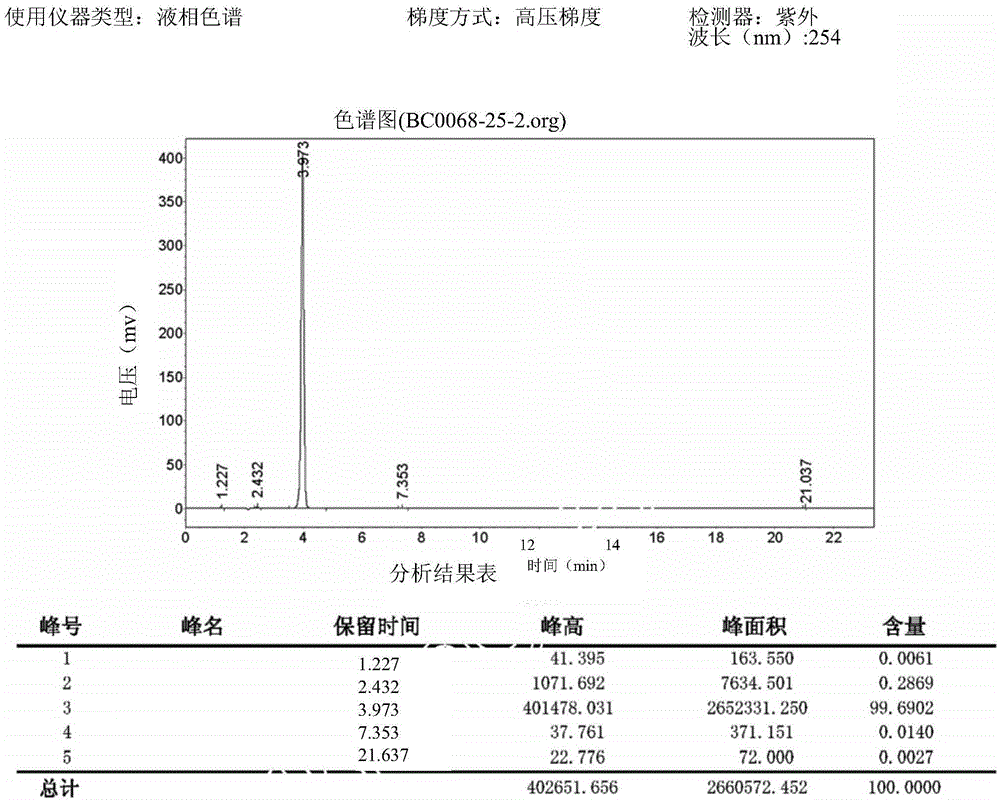

[0035] Add the raw material fluorene (60g) to N,N-dimethylformamide (450ml), under nitrogen protection, stir until the solids are completely dissolved, then cool to 0°C, add sodium hydride (36g, 3-4 times, 15 minutes to complete the addition), and maintain the temperature between 0 and 5°C (a large amount of gas is released). After the addition, the temperature in the reaction flask was kept at 0-10°C. After stirring for one hour, it was cooled to 0°C again, and then ethylene oxide (36ml) was diluted with N,N-dimethylformamide (30ml). Add it into the reaction bottle (addition is completed in one minute), after the addition is completed, slowly rise to 15°C, and keep it warm for 5 hours. After treatment, the reaction mixture was slowly poured into 480g of ice water to quench, and then extracted with EA (ethyl acetate) (480ml×3), the organic phase was combined, and the organic phase was washed once with saturated brine (480ml), and sulfuric acid was added Sodium dry. After fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com