A kind of road asphalt modifier and preparation method thereof

A technology of road asphalt and modifier, applied in chemical instruments and methods, building components, fibrous fillers, etc., can solve problems such as difficult-to-peel montmorillonite structure, improve rheological properties and anti-aging properties, High anti-aging performance and the effect of increasing hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

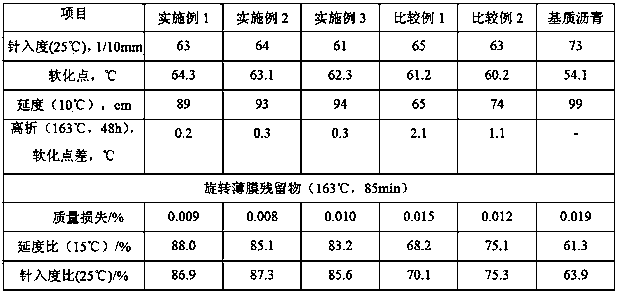

Examples

Embodiment 1

[0027] Preparation of organic montmorillonite:

[0028] Among them, the content of montmorillonite in montmorillonite is more than 97%, and its particle size is 10um. Polyphosphoric acid has a degree of polymerization of 100.

[0029] (1) Under the condition of high-speed stirring (1500r / min), quickly add montmorillonite to polyphosphoric acid ethanol solution, keep stirring for 20 minutes, and filter with suction.

[0030] (2) Add the dodecylamine ethanol solution to the filter cake in step (1), stir for 1 hour after the addition, and filter with suction.

[0031] (3) Washing and vacuum drying to finally obtain organic montmorillonite with good particle dispersion, fluffy and no need for grinding.

[0032] Wherein, wherein the weight content of each substance is:

[0033] Montmorillonite: 25%

[0034] Polyphosphoric acid: 25%

[0035] Dodecylamine: 50%

[0036] The preparation of organic montmorillonite modified asphalt is as follows:

[0037] The organic montmorilloni...

Embodiment 2

[0039] Preparation of organic montmorillonite:

[0040] Among them, the content of montmorillonite in montmorillonite is more than 97%, and its particle size is 10um. Polyphosphoric acid has a degree of polymerization of 100.

[0041] (1) Under the condition of high-speed stirring (1500r / min), quickly add montmorillonite to polyphosphoric acid ethanol solution, keep stirring for 20 minutes, and filter with suction.

[0042] (2) Add cetylamine ethanol solution to the filter cake in step (1), stir for 1 hour after the addition is complete, and filter with suction.

[0043] (3) Washing and vacuum drying to finally obtain organic montmorillonite with good particle dispersion, fluffy and no need for grinding.

[0044] Wherein, wherein the weight content of each substance is:

[0045] Montmorillonite: 25%

[0046] Polyphosphoric acid: 30%

[0047] Cetylamine: 45%

[0048] The preparation of organic montmorillonite modified asphalt is as follows:

[0049] The organic montmoril...

Embodiment 3

[0051] Preparation of organic montmorillonite:

[0052] Among them, the content of montmorillonite in montmorillonite is more than 97%, and its particle size is 10um. Polyphosphoric acid has a degree of polymerization of 100.

[0053] (1) Under the condition of high-speed stirring (1500r / min), quickly add montmorillonite to polyphosphoric acid ethanol solution, keep stirring for 20 minutes, and filter with suction.

[0054] (2) Add the stearylamine ethanol solution to the filter cake in step (1), stir for 1 hour after the addition, and filter with suction.

[0055] (3) Washing and vacuum drying to finally obtain organic montmorillonite with good particle dispersion, fluffy and no need for grinding.

[0056] Wherein, wherein the weight content of each substance is:

[0057] Montmorillonite: 25%

[0058] Polyphosphoric acid: 35%

[0059] Octadecylamine: 45%

[0060] The preparation of organic montmorillonite modified asphalt is as follows:

[0061] The organic montmorilloni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com