Modified polylactic acid compound 3D printing material with wood property, as well as preparation method and application thereof

A 3D printing and polylactic acid technology, which is applied in the field of modified polylactic acid composite 3D printing materials and preparation, can solve the problems of no antibacterial, antifouling and self-cleaning functions, adverse effects on human health, enrichment of pollutants, etc., and achieve improvement of expansion plugging The phenomenon of scratches, the improvement of material strength, and the effect of good antibacterial ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

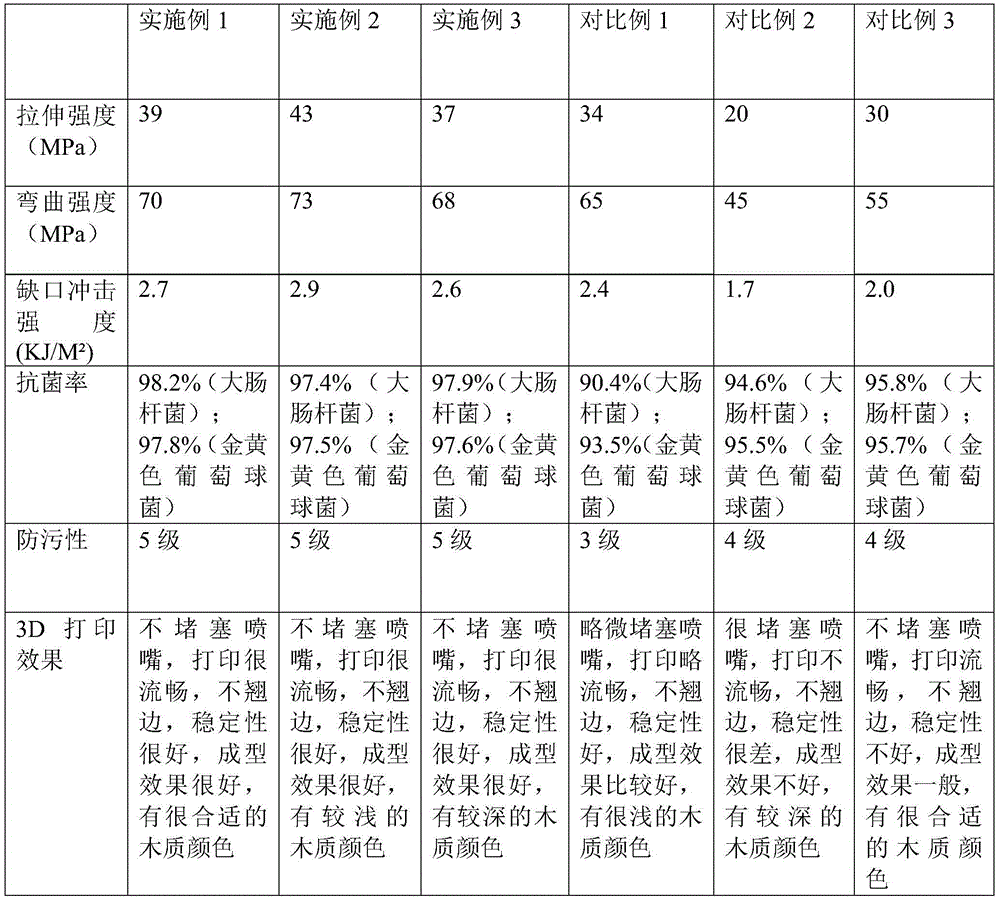

Examples

Embodiment 1

[0053] (1) Formula dosage (parts by mass): 70 parts of polylactic acid PLA (molecular weight: 70,000), 20.5 parts of natural sandalwood powder, 3 parts of silane coupling agent (KH570), 5 parts of thermoplastic elastomer (SEBS), nano antibacterial agent (nano titanium dioxide) 1.5 parts.

[0054] (2) Preparation process:

[0055] ① Put the PLA into the dryer and bake at 100°C for 3 hours to completely evaporate the water;

[0056] ②Then put the natural sandalwood powder into a sodium hydroxide solution with a concentration of 10% by mass for alkali treatment: soak the wood powder in a sodium hydroxide solution (10%), with a mass ratio of 1:15, and stir at room temperature After 24 hours, let stand to pour off the upper layer of lye, add distilled water to wash, filter with filter cloth, repeat several times until the filtrate is neutral, then dry to constant weight and use it as one of the raw materials for later use;

[0057] ③ Put each raw material into the mixer according...

Embodiment 2

[0059] (1) Formula dosage (parts by mass): 90 parts of polylactic acid PLA (molecular weight 70,000), 7.5 parts of environmentally friendly natural miscellaneous wood fiber powder (about 400 mesh), 1 part of silane coupling agent (KH590), thermoplastic elastomer (SEBS ) 1 part, 0.5 part of nano antibacterial agent (nano-titanium dioxide).

[0060] (2) Preparation process:

[0061] ① Put the PLA into the dryer and bake at 100°C for 3 hours to completely evaporate the water;

[0062] ②Then put the environment-friendly natural miscellaneous wood fiber powder into a sodium hydroxide solution with a concentration of 10% by mass for alkali treatment: soak the wood powder in a sodium hydroxide solution (10%), with a mass ratio of 1:15, at room temperature Stir for 24 hours, let stand and pour off the upper layer of lye, add distilled water to wash, filter with filter cloth, repeat several times until the filtrate is neutral, then dry to constant weight and use it as one of the raw m...

Embodiment 3

[0065] (1) Formula dosage (parts by mass): 80 parts of polylactic acid PLA (70,000 molecular weight), 15 parts of mahogany wood powder (about 300 mesh), 1.5 parts of silane coupling agent (KH550), 2.5 parts of thermoplastic elastomer (SEBS) , 1 part of nano antibacterial agent (nano titanium dioxide).

[0066] (2) Preparation process:

[0067] ① Put the PLA into the dryer and bake at 100°C for 3 hours to completely evaporate the water;

[0068] ②Then put the natural eucalyptus powder into a sodium hydroxide solution with a concentration of 10% by mass for alkali treatment: soak the wood powder in a sodium hydroxide solution (10%), with a mass ratio of 1:15, and stir at room temperature for 24 Hours, stand and pour off the upper layer of lye, add distilled water to wash, filter with filter cloth, repeat for many times until the filtrate is neutral, and then dry to constant weight as one of the raw materials for subsequent use;

[0069] ③Put each raw material into the mixer ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com