A kind of cmos circuit based on flexible thin film transistor and its manufacturing method

A thin film transistor and flexible thin film technology, which is applied in the field of semiconductor device and circuit manufacturing, can solve the problems of limited device size, small-sized device fabrication and uniformity, etc., so as to reduce process complexity and cost, improve uniformity and high gain. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

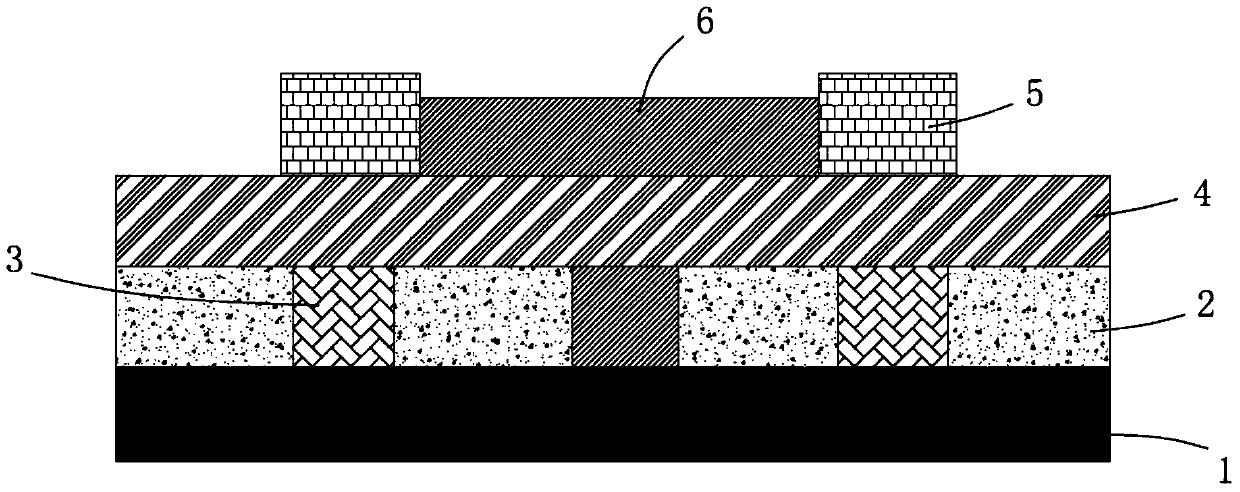

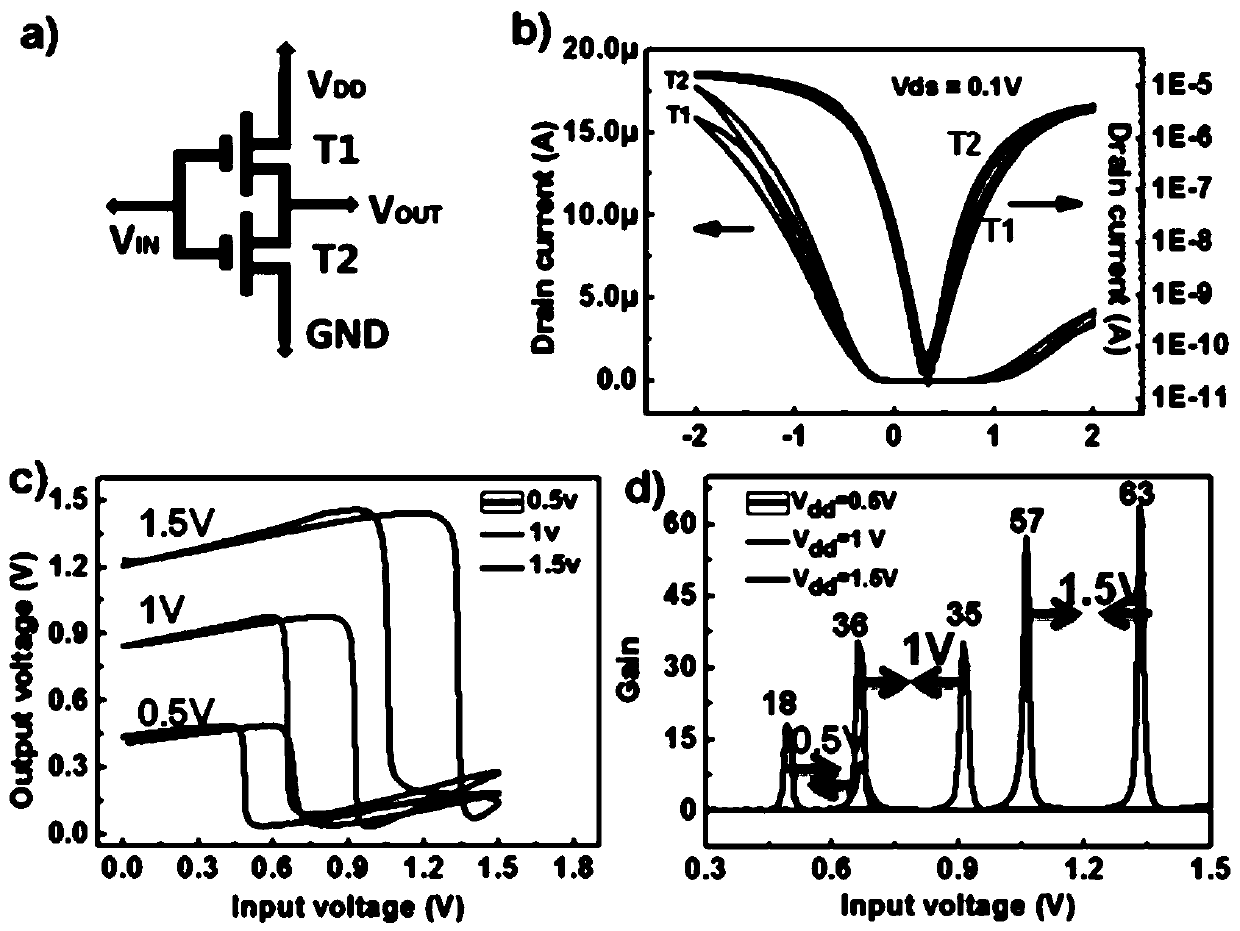

[0030] Example 1: A semiconductor carbon nanotube CMOS inverter with a top-gate structure and its preparation.

[0031] Such as figure 1 Shown is a carbon nanotube CMOS inverter with atomically deposited hafnium oxide of a certain thickness as the gate dielectric 4 and nano-silver as the top gate 5 . The source and drain electrodes 2 of the two transistors are all gold electrodes deposited by electron beam evaporation, and the channel region between each source and drain electrode is a semiconducting carbon nanotube 3 deposited by printing, forming two complete bipolar Sexual transistor devices.

[0032] Connect the drain electrode of one of the transistors to the drain electrode of the other transistor, and its potential is the output voltage (Vout) of the inverter. Connect the gates 5 of the two transistors with a conductive material 6, and its voltage is used as the input voltage (Vin), thus forming a CMOS inverter circuit. The schematic diagram of the inverter can be fou...

Embodiment 2

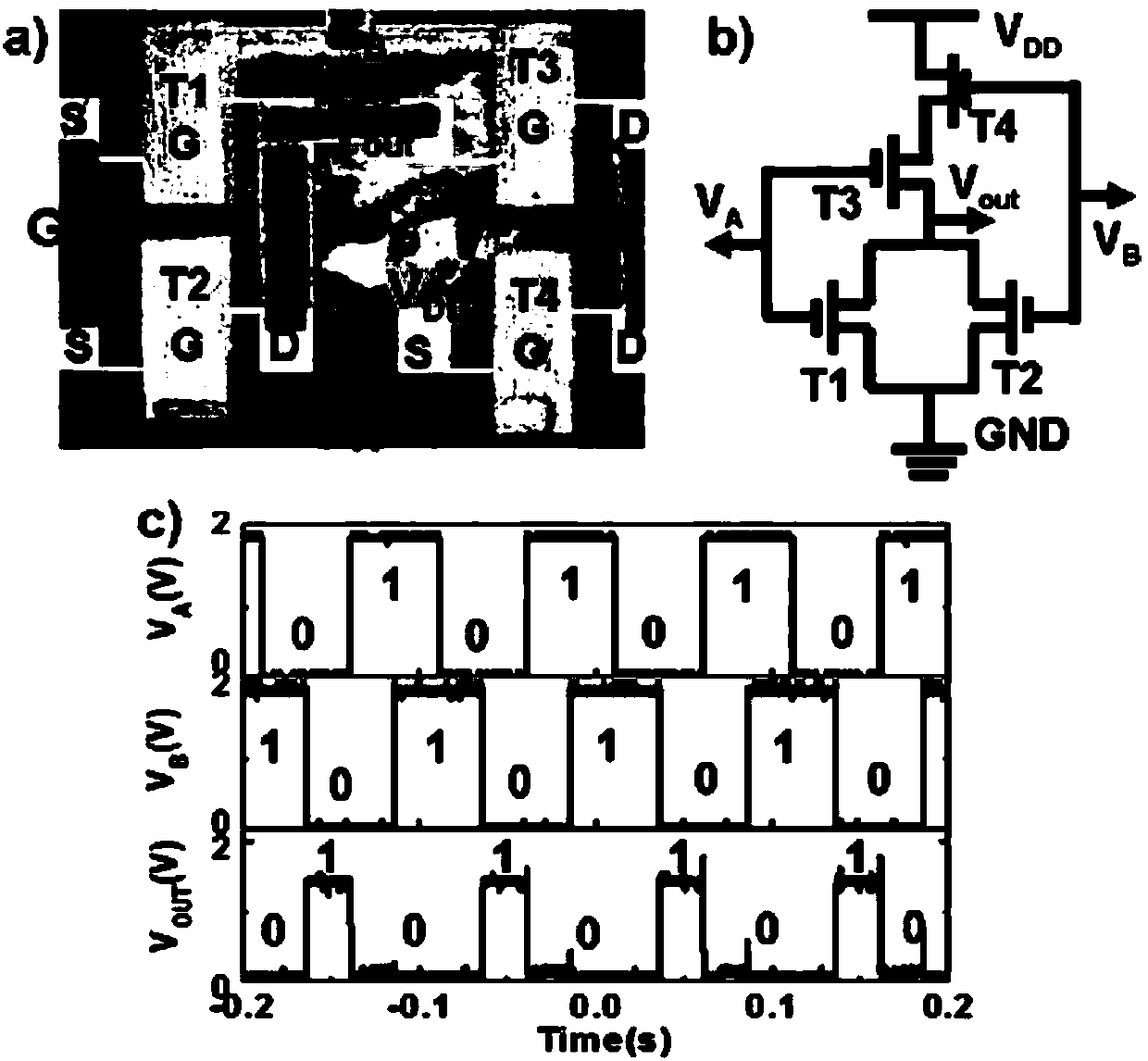

[0040] Example 2: Carbon nanotube CMOS NOR gate circuit with top gate structure

[0041] Such as image 3 As shown, adopt the step of embodiment 1 to prepare a plurality of bipolar field effect transistors, and according to image 3 As shown in (a) and (b), the source, drain and gate electrodes are connected to obtain an undoped CMOS NOR gate circuit based on carbon nanotubes. When V 1 =VDD,V 2 When =GND, the logic circuit realizes the NOR gate logic function. NOR gate is when two signal sources V A , V B When both are low level (0,0), the output is high level 1, as long as one is high level 1, then the output is low level 0. Depend on image 3 As shown in (c), it exhibits a good NOR logic function.

Embodiment 3

[0042] Embodiment 3: Carbon nanotube CMOS ring oscillator with top gate structure

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com