Pulse optical fiber laser and method for realizing time domain pulse slicing by using the same

A technology of fiber lasers and lasers, applied in lasers, laser components, phonon exciters, etc., can solve problems such as unpredictable and uncontrollable physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

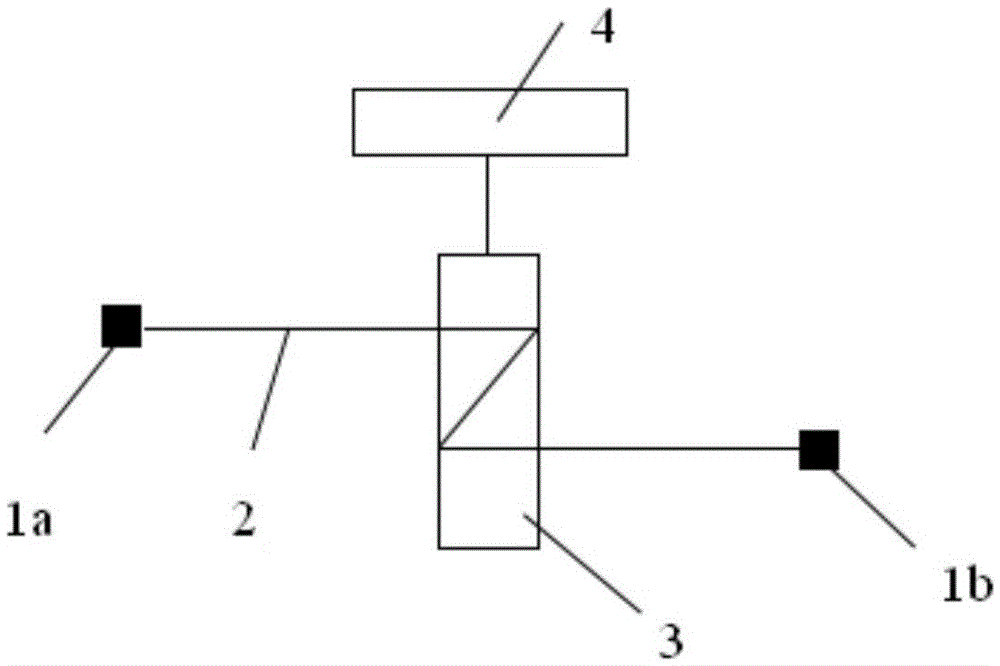

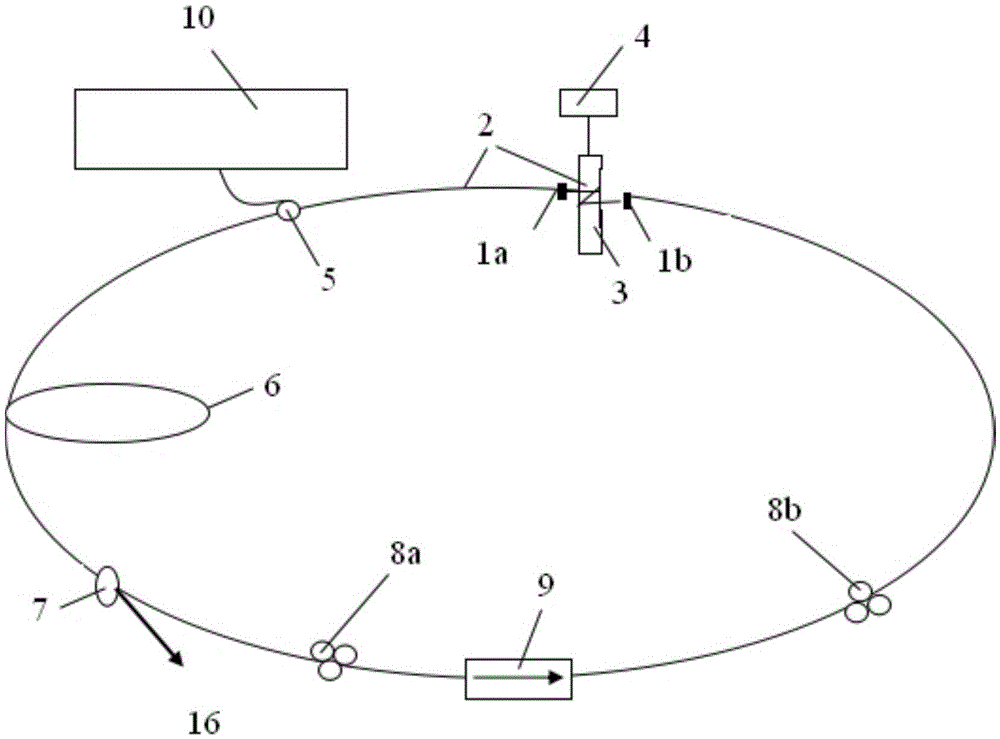

[0033] Such as figure 1 and figure 2As shown, the pulsed fiber laser includes a pumping laser 10, a gain fiber 6, a fiber coupler 7, a polarization-dependent isolator 9, a wavelength division multiplexer 5, a first polarization controller 8a and a second polarization controller 8b, the main The resonant cavity is a ring cavity, and a microcavity is also provided in the main resonant cavity, and the microcavity includes a first cavity mirror 1a, a second cavity mirror 1b, a single-mode optical fiber 2, a piezoelectric ceramic 3 and an external control device connected to the piezoelectric ceramic 3. A voltage module 4, a single-mode optical fiber 2 wound on a piezoelectric ceramic 3 and its two ends are respectively connected to the first cavity mirror 1a and the second cavity mirror 1b, the pumping laser 10 is connected to an input end of the wavelength division multiplexer 5, the second A cavity mirror 1a is connected to the other input end of the wavelength division multip...

Embodiment 2

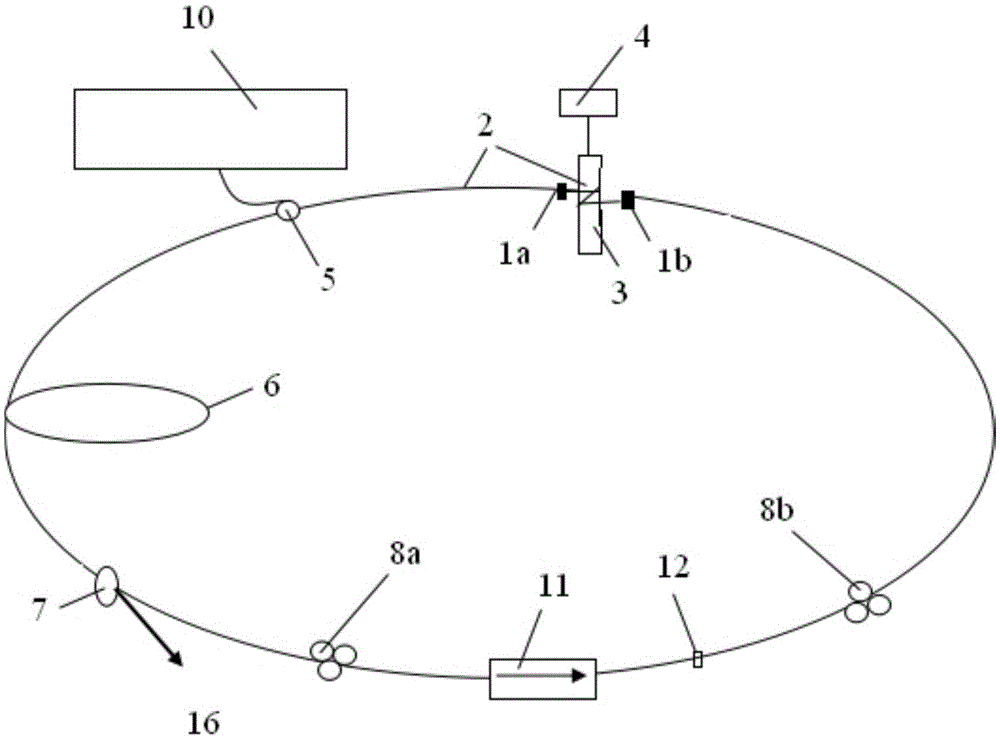

[0037] pulsed fiber lasers, such as image 3 As shown, the main resonant cavity is a ring cavity, except that the polarization-independent isolator 11 and the saturable absorber 12 are sequentially connected between the first polarization controller 8a and the second polarization controller 8b. 1 is exactly the same.

[0038] The saturable absorber 12 adopts commercial graphene, and can also be carbon nanotubes, black phosphorus, topological insulators, sulfide series two-dimensional materials, selenide series two-dimensional materials, semiconductor absorber materials, gold or silver nanorods one-dimensional Material, alcohol or composite inks, which can also be self-prepared, function to generate self-starting pulses through the optical saturable absorption effect.

[0039] The pulsed fiber laser of Example 2 is used for time-domain pulse slicing, and the saturable absorber 12 is used to replace the non-linear polarization rotation effect of Example 1. The physical effect o...

Embodiment 3

[0041] pulsed fiber lasers, such as Figure 4 As shown, the main resonant cavity is an "8" shaped cavity, except that there is no polarization-dependent isolator 9, and a 2×2 fiber coupler 13 with a splitting ratio of 3dB and a polarization-independent isolator 11 are added, all other components are exactly the same as in Embodiment 1. same,

[0042] The two fiber ends on the same side of the 2×2 fiber coupler 13 are respectively butted to form an "8" shape, which constitutes the main resonant cavity of the fiber laser. The pump laser 10 is connected to an input end of the wavelength division multiplexer 5, along the The output end of the wavelength division multiplexer 5 is sequentially connected to the gain fiber 6, one fiber end on the left side of the 2×2 fiber coupler 13, and the other fiber end on the left side of the 2×2 fiber coupler 13 is connected to the first polarization controller 8a , the first polarization controller 8a is connected to the other input end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com