Patents

Literature

46 results about "Slice Number" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Media slicing memory method

InactiveCN101137027AImprove storage efficiencyImprove efficiencyTelevision system detailsColor television detailsComputational scienceEngineering

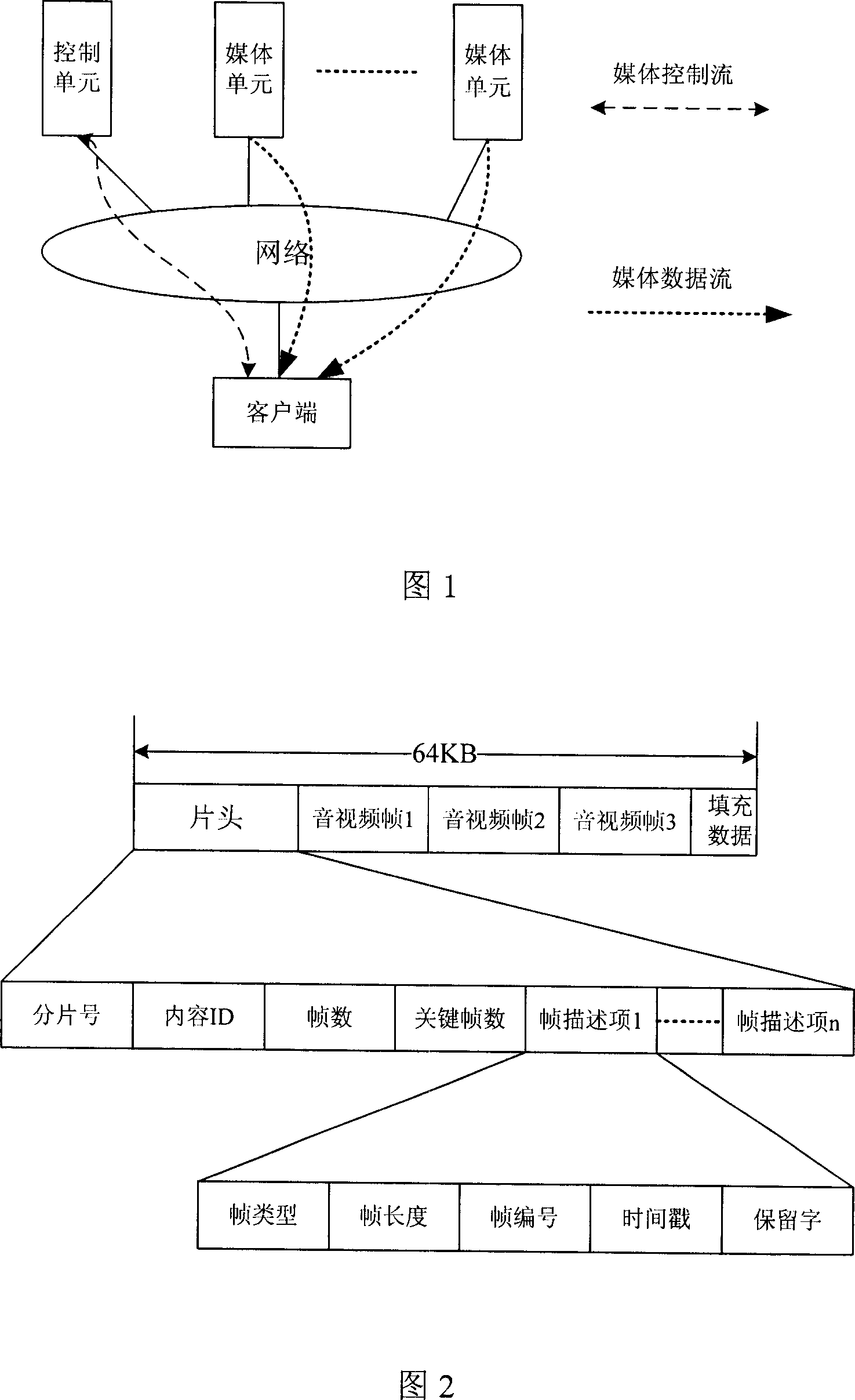

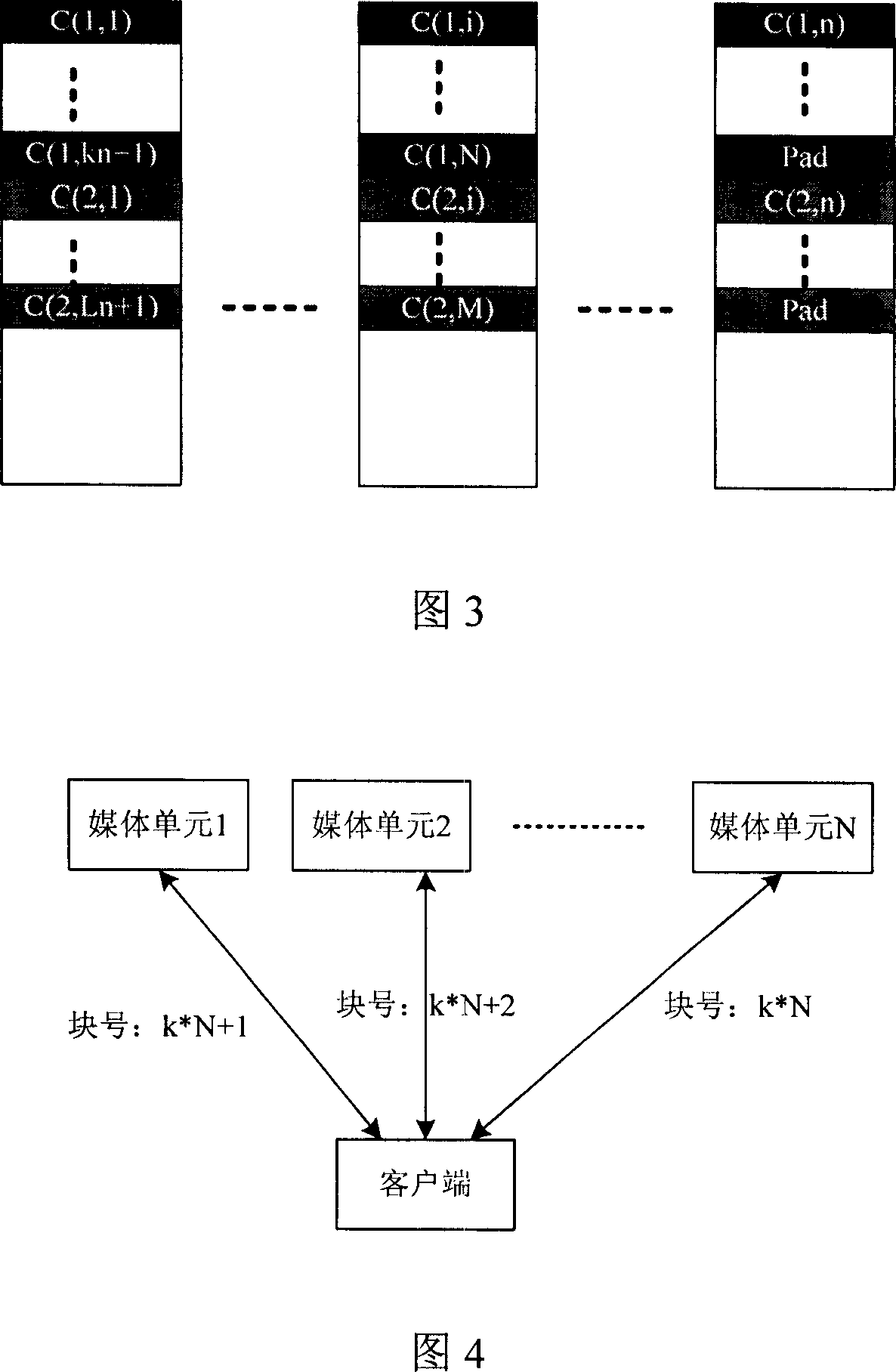

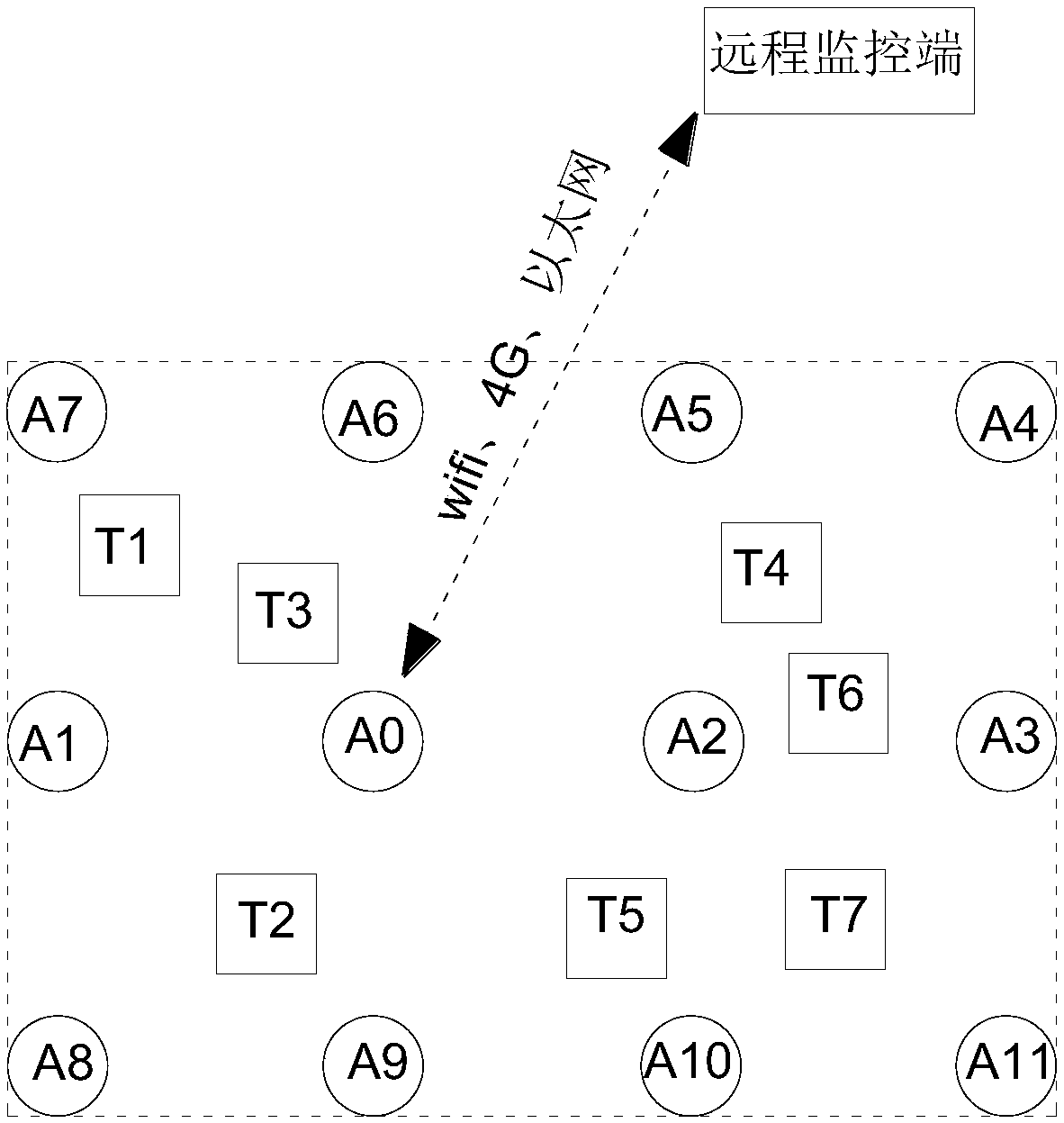

The method includes: 1, Divide the media file into several fragments. Each fragment forms a slice with fixed size. Each slice at least includes one slice head and one data area. The head at least includes the slice number and the media label corresponding to this slice. The data area is for storing audio / video frame of the fragment corresponding to the slice according to the time stamp sequence; 2, Store evenly the formed slices in step 1 into several media units and build the storage record. This invention is mainly applied in grouped VOD system. It enhances storage efficiency, retrenches tediously load-balance calculation and increases the system expansibility.

Owner:ZTE CORP

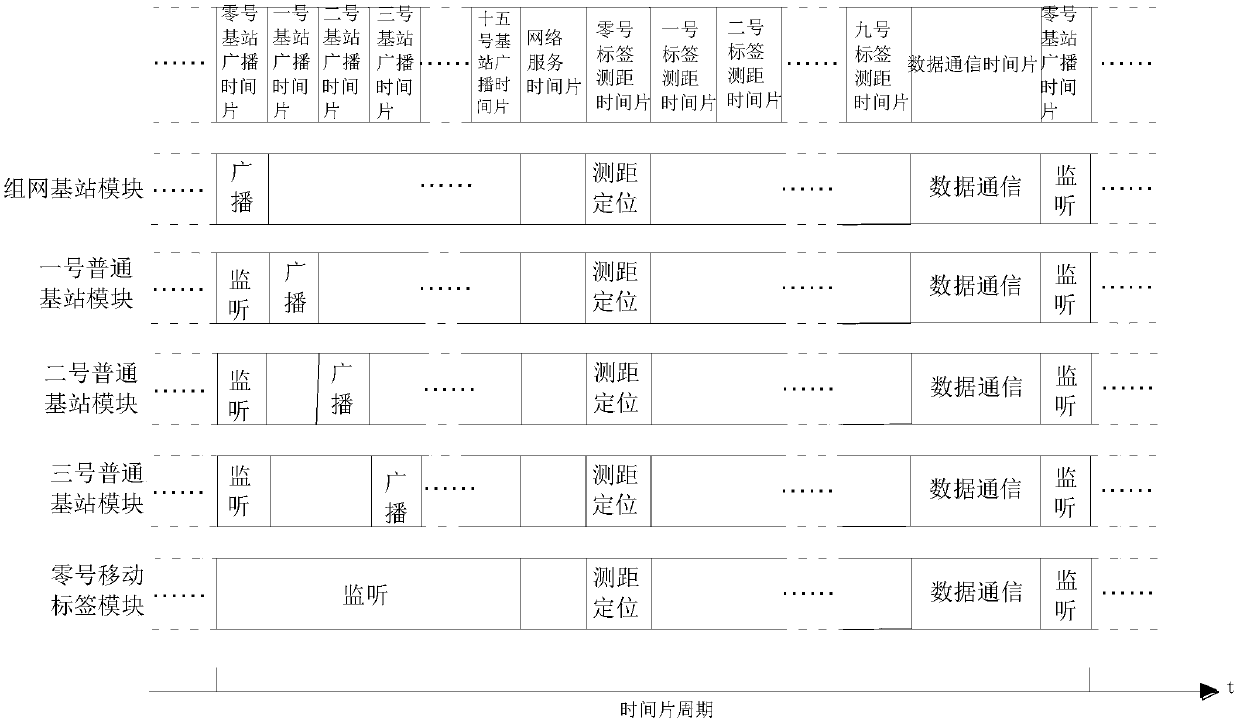

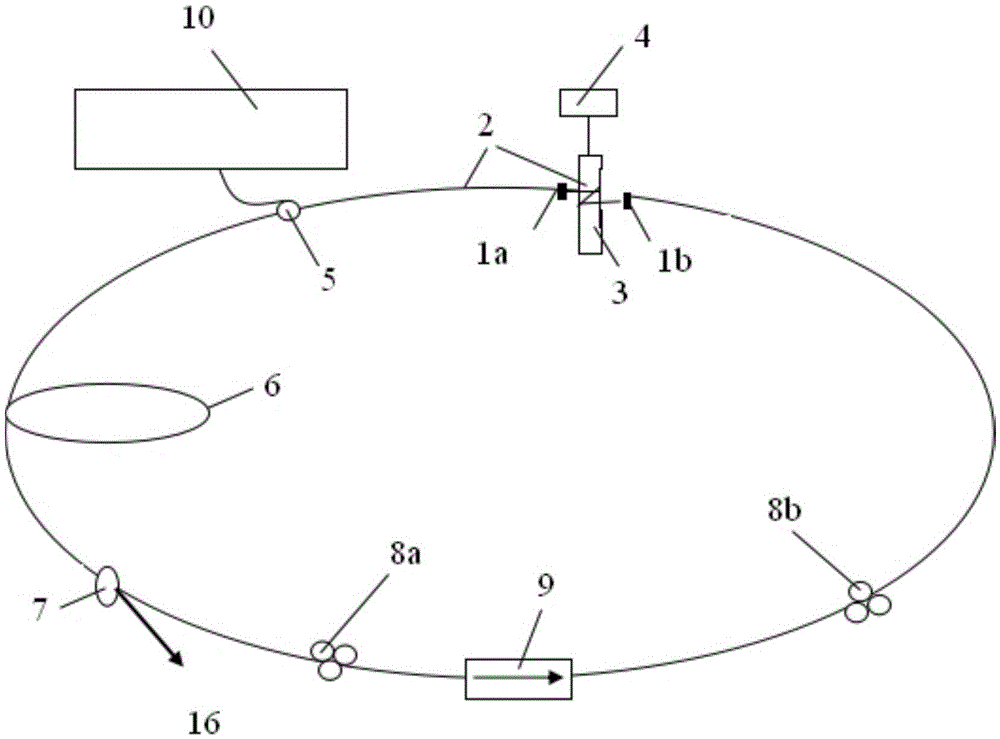

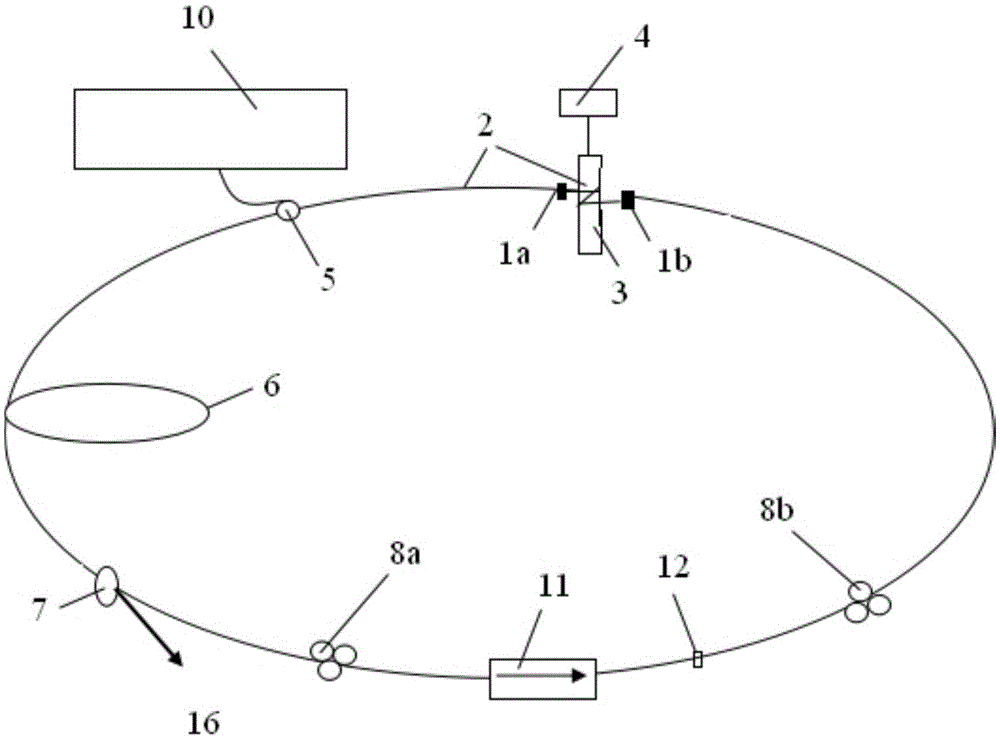

Networking method for ultra-wideband wireless communication indoor positioning system

ActiveCN109640268ARealize interconnection and mutual knowledgeRealize remote management functionParticular environment based servicesBroadcast service distributionUltra-widebandTime-sharing

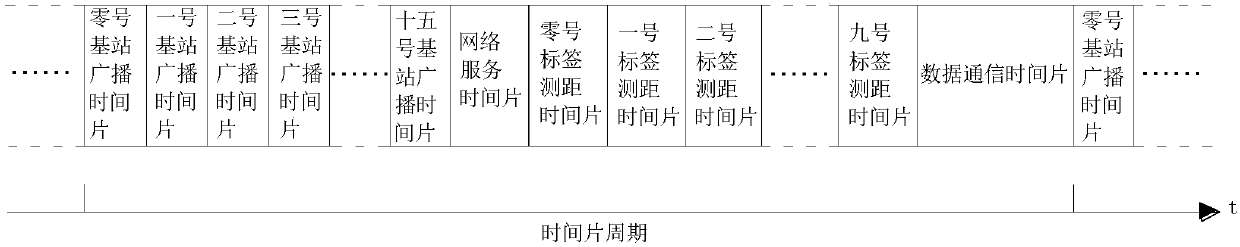

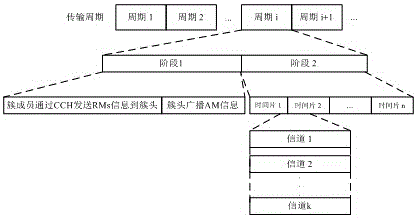

The invention discloses a networking method for an ultra-wideband wireless communication indoor positioning system. A time slice period is initiated by a networking base station module: a scheduling of the time slice period, the time increases from left to right, 16 base station broadcast time slices are reserved, zero base station broadcast time slice-15th base station broadcast time slice, respectively; one network service time slice and 10 tag ranging time slices are number zero tag ranging time slice-number nine tag ranging time slice, respectively; and one data communication time slice. In the method in the invention, the time slice method is adopted to realize time-sharing operation of different functions, thereby greatly reducing the communication conflict problem of multiple modules in an Ultra-Wideband (UWB) local area network; all the modules in the application scenario are connected into the unified UWB local area network, interconnection and mutual understanding are achieved between the modules in the network, and interfaces such as WiFi and Ethernet are provided to the outside, thereby realizing a remote management function of the UWB local area network.

Owner:长沙智能机器人研究院有限公司

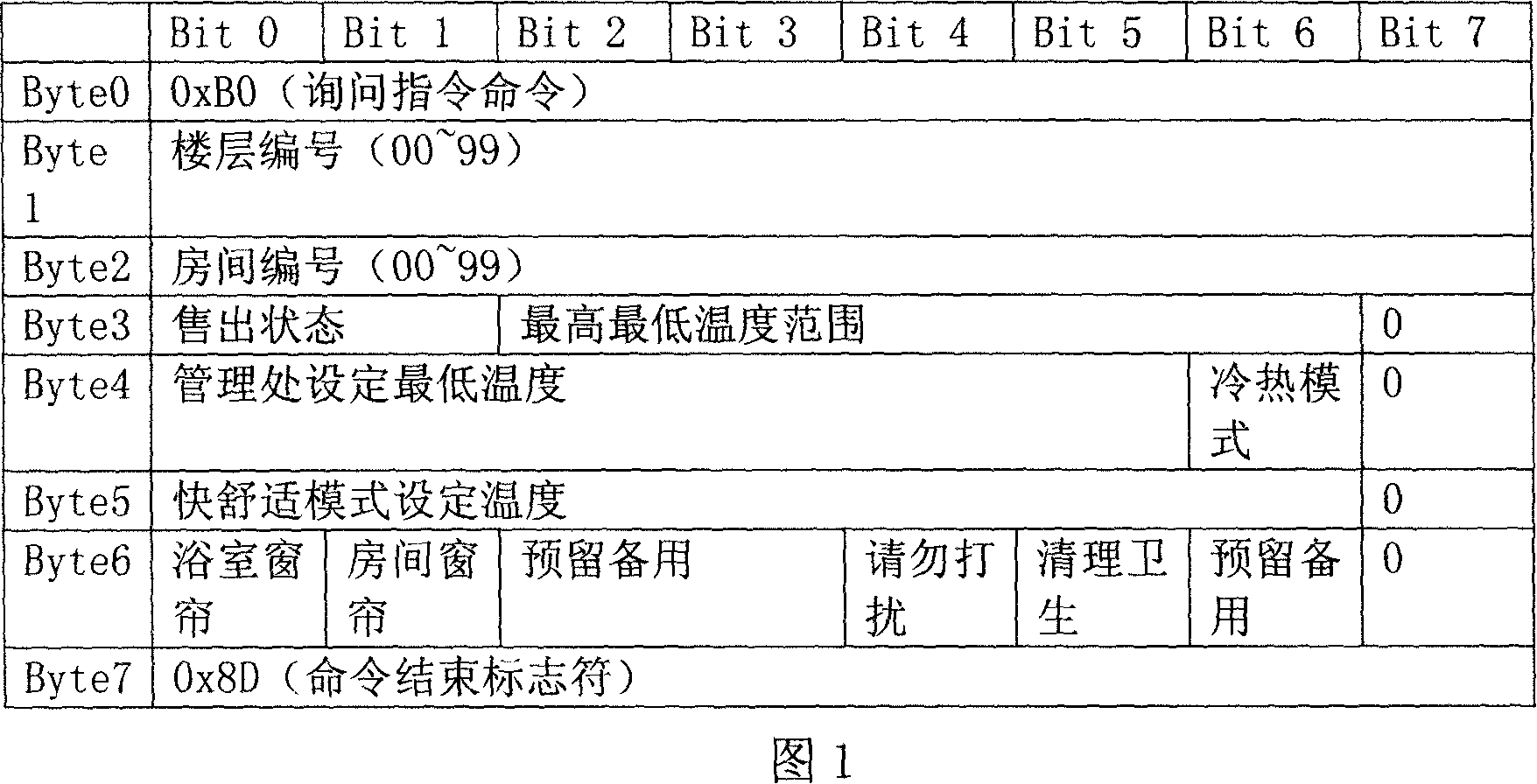

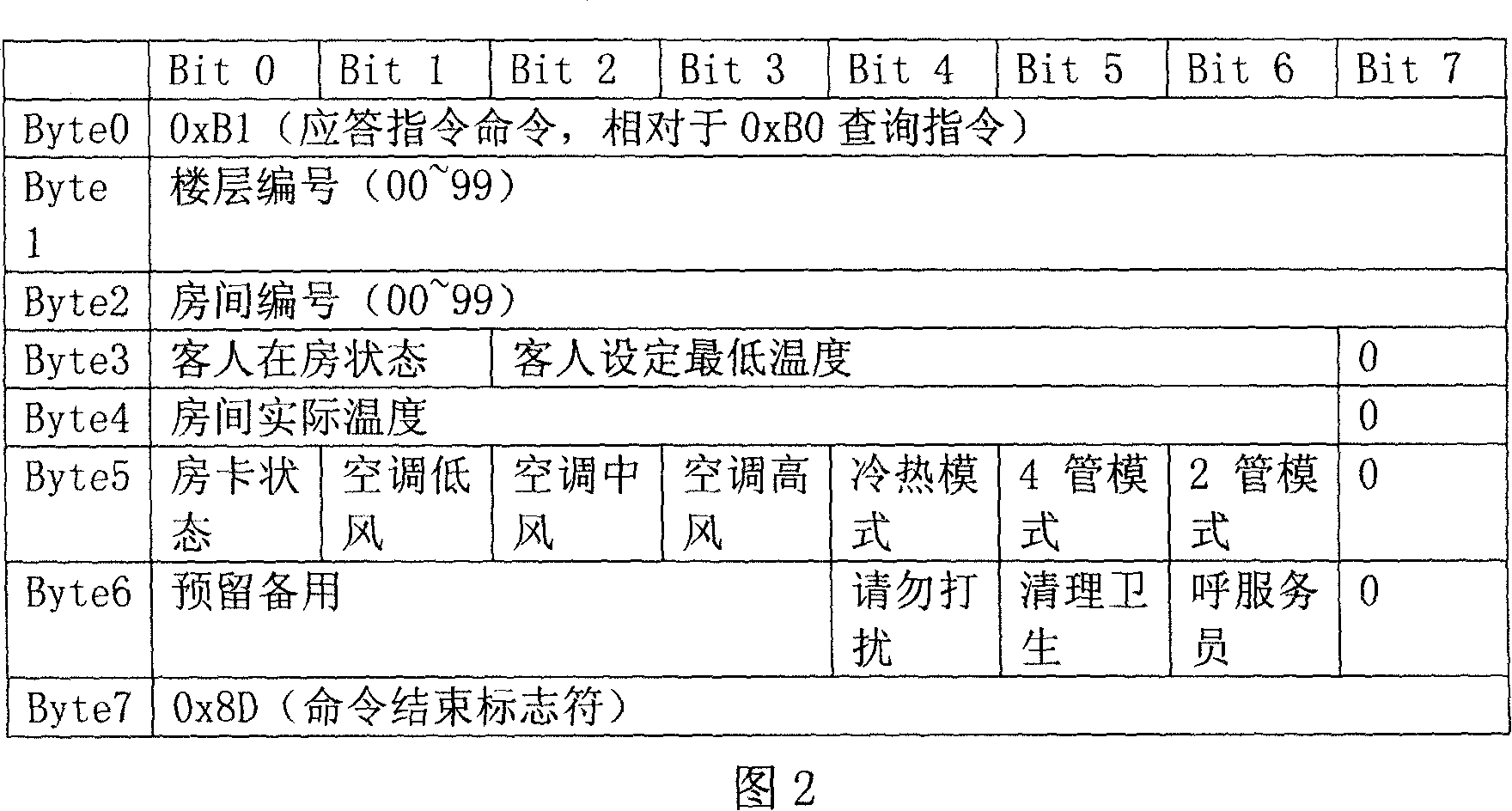

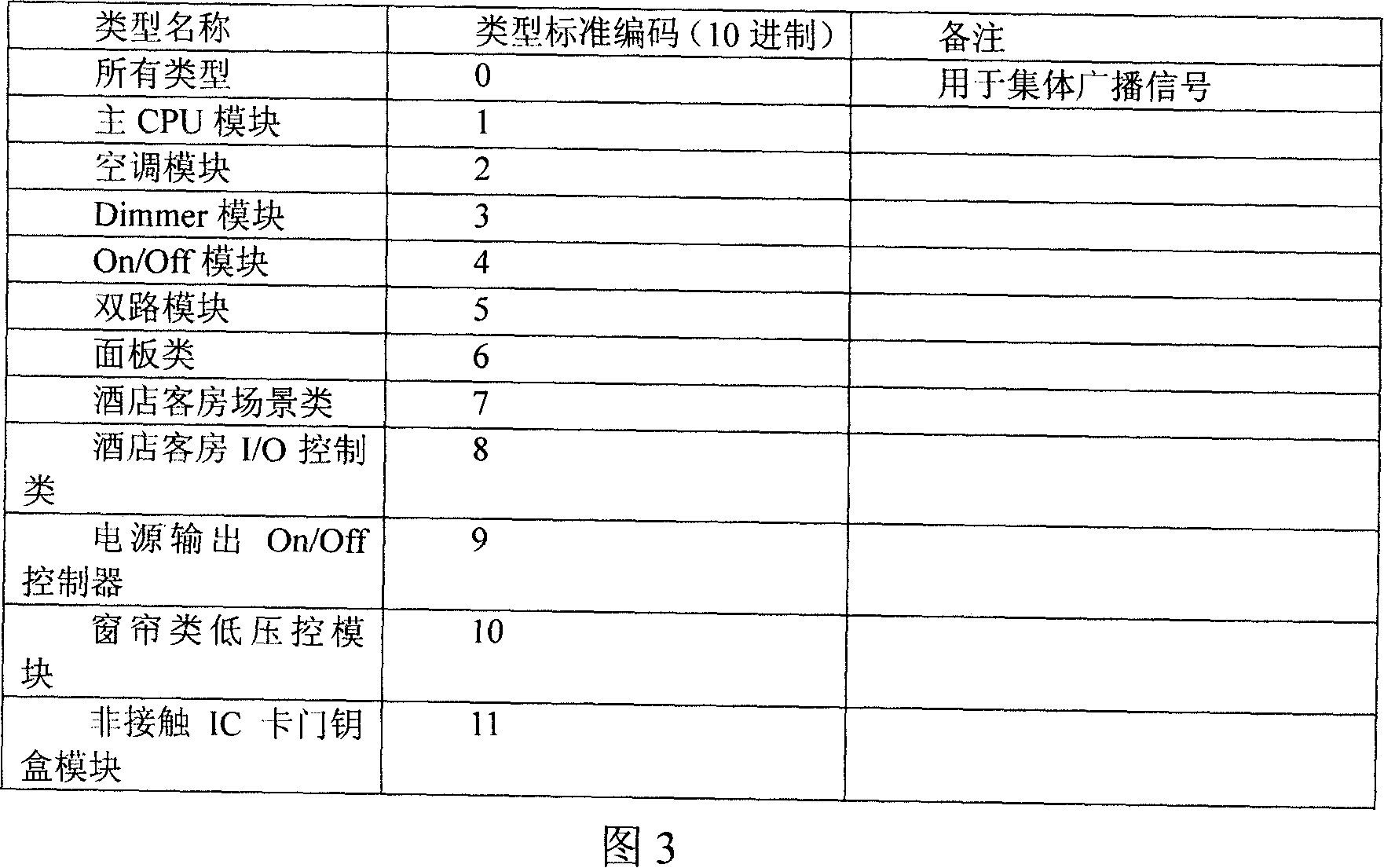

Data communication coding method

This invention relates to a data communication coding method used in radio communication and site bus communication transmission, in which, the transmission format protocol includes: OxAA, Ox55, a module kind of a receiving unit, the internal relative number, data packet length and ciphered algorithm numbers of the receiving unit, the model kind of the transmission unit, the internal relative number of the module kind of the transmission unit, the internal device control port number of the order-executing module / the key assignments kind internal number of a panel module device, the kind number of the order-executing module, the action instruction number, parameter number, parameter sequence number, slice numbers of the parameter of its standard instruction, sequence number of the action instruction of the standard instruction, content of the parameter data, a check code, OxFF and OxFF, in which, the OxAA and Ox55 are two starting identifying bytes of an instruction packet and the OxFF and OxFF are two ending identifying bytes of the instruction packet.

Owner:宝丽雅智能系统(深圳)有限公司 +1

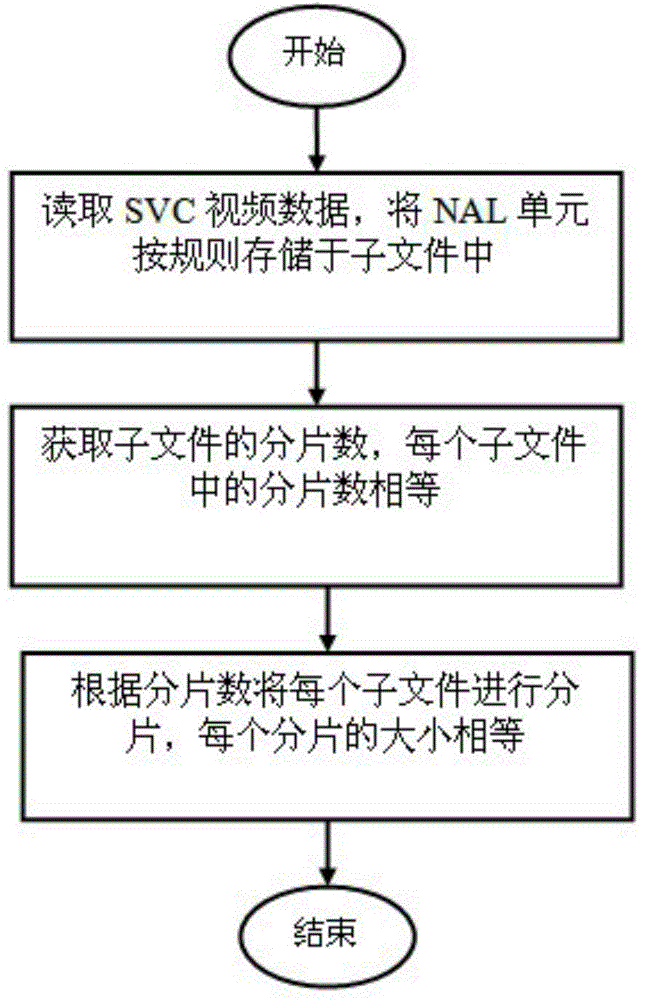

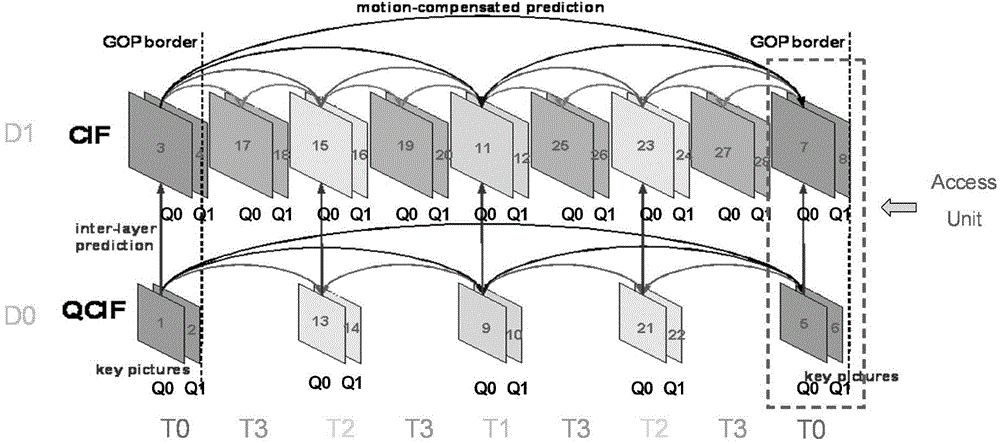

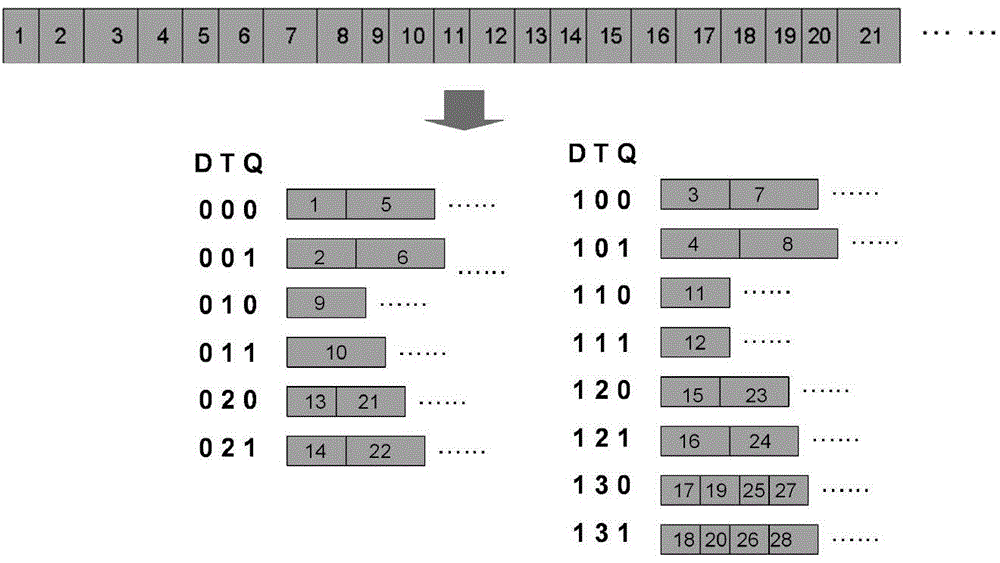

A slicing method for SVC video files in a P2P streaming media system

InactiveCN103607667AImprove synchronizationQuality improvementSelective content distributionStatistical analysisFile size

The invention discloses a slicing method for SVC video files in a P2P streaming media system. The slicing method for the SVC video files in the P2P streaming media system comprises the following steps: S1, SVC video data is read, and NAL units with equal triple values (D,T,Q) in NAL head information are stored in a same subfile, and at the same time, the file size C (i, j, k) of each subfile is subjected to statistical analysis and is stored; S2, each subfile is uniformly divided into N slices; and a maximum value of each slice is preset to be Smax, and the minimum value of each slice is preset to be Smin, so that a slice number N is any integer in accordance with the following formula, and the slice number N in each subfile is equal to the slice number of any other subfile; S3, according to the slice number N calculated according to the step S2, slicing is carried out on each subfile, and the size of each slice in each subfile is equal to the size of any other slice according to a data filling method. According to the slicing method for the SVC video files in the P2P streaming media system, costs spent on servers and networks are reduced, and synchronization and coordination quality of videos are raised.

Owner:NANJING YUNCHUAN INFORMATION TECH

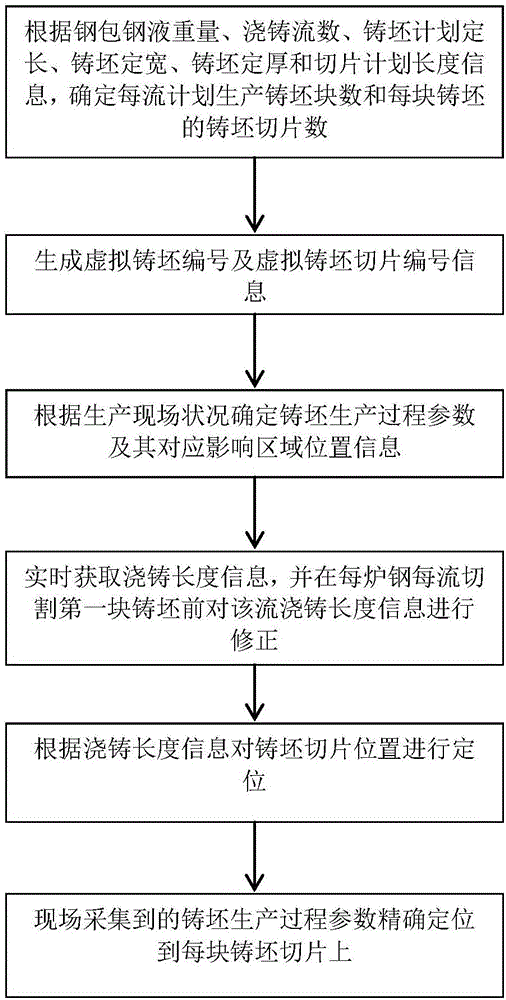

Method for accurately positioning casting blank production process parameters to casting blank slices

The invention belongs to the field of intelligent control of continuous casting production processes, and especially relates to a method for accurately positioning casting blank production process parameters to casting blank slices. The method comprises the steps of (1) determining the number of per-flow planned production casting blanks and casting blank slices according to molten steel weight and casting blank planned sizing information; (2) generating virtual casting blank numbers and virtual casting blank slice numbers per flow; (3) determining the casting blank production process parameters and corresponding affected area positional information according to production filed equipment status; (4) obtaining per-flow casting length in real time, and correcting the casting length of the flow before cutting the first casting blank per flow per furnace steel; (5) determining positions of the casting blank slices according to the casting length per flow; and (6) positioning the casting blank production process parameters acquired in real time to each casting blank slice according to the step (3) and the step (5). The casting length is corrected and furthermore the production process parameters are accurately positioned to the casting blank slices, and accuracy of casting blank slice quality defect determination is improved.

Owner:CENT IRON & STEEL RES INST +1

Pulse optical fiber laser and method for realizing time domain pulse slicing by using the same

InactiveCN105591273AAdjustable number of slicesCoherent bound propertyActive medium shape and constructionResonant cavityTime domain

The invention discloses a pulse optical fiber laser including a pumping laser, a main resonant cavity, and a gain optical fiber arranged in the main resonant cavity. A micro-cavity is arranged in the main resonant cavity and includes a first cavity lens, a second cavity lens, a single mode optical fiber, a piezoelectric ceramic and an external control voltage module connected to the piezoelectric ceramic. The invention also discloses a method for realizing time domain pulse slicing by using the pulse optical fiber laser. The external control voltage module controls a voltage applied to the piezoelectric ceramic, so that the single mode optical fiber generates change in a longitudinal direction, thereby causing dynamic change of the micro-cavity length and performing dynamic slicing with continuous adjustable time domain interval and slice number on a single pulse. The micro-cavity of the pulse optical fiber laser is not limited by an embedded position, can perform effective and controllable dynamic slicing on the single pulse with an ns-ps order, and is widely applied to the ultrafast laser technical field, the optical fiber optics field and the time domain precision measurement field.

Owner:FOSHAN UNIVERSITY

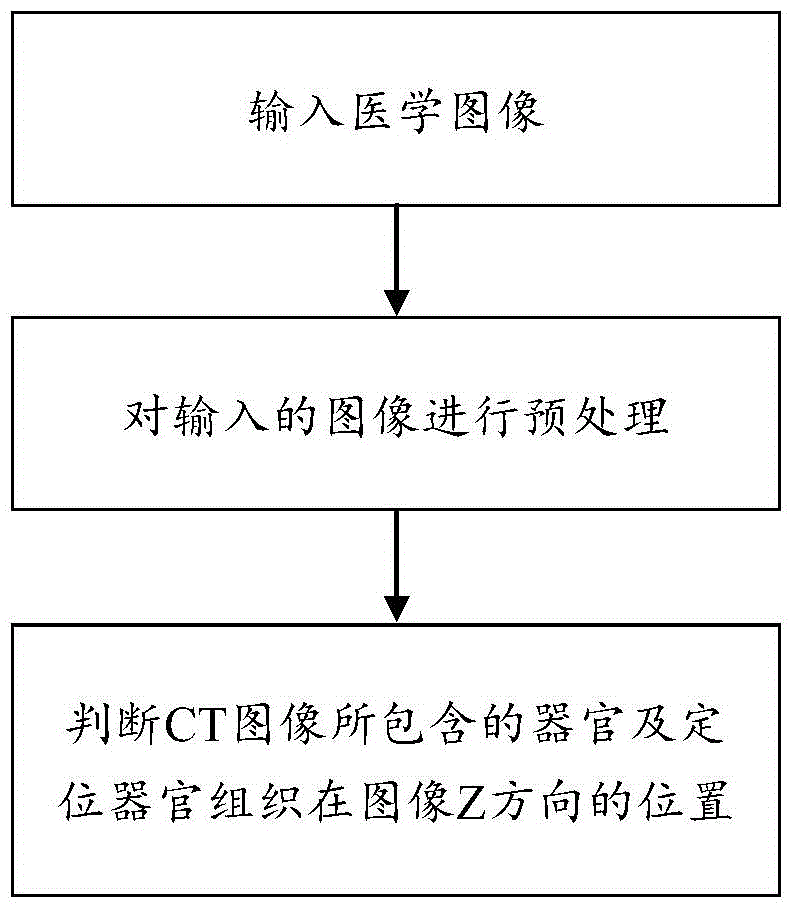

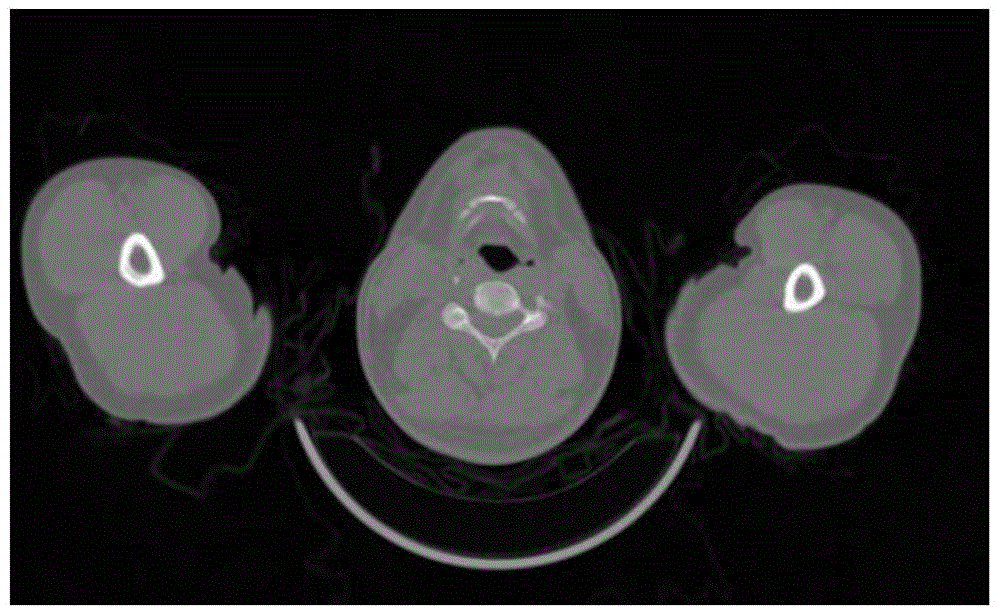

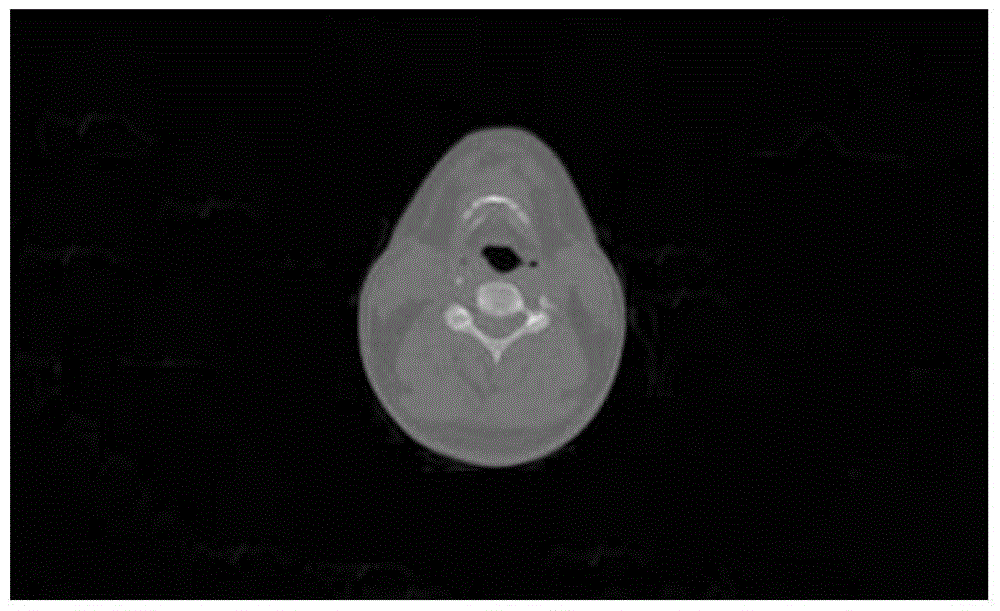

Method for positioning organs in medical image

The invention discloses a method for positioning organs in a medical image. The method comprises following steps of step S1, inputting the medical image containing a plurality of slice images; step S2, preprocessing the input images; filtering non-body pixels; step S3, calculating the number of connected domains of each layer of slice image; through judging the numbers and the positions of the connected domains, removing the parts except first organs; confirming that the medical image contains the first organs; calculating the feature value of each layer of slice image, thus obtaining a plurality of feature values; forming a feature curve by the plurality of feature values and the slice number of the slice images; wherein the step of calculating the feature value comprises with respect to each layer of slice image, calculating the proportion of a pixel area of the pixel gray value or CT value relative to the whole body pixel area in a first range; and positioning the slice images in which the organs are located according to the proportions. According to the settings, the ranges in which the organs are located can be positioned rapidly, and the accuracy is high.

Owner:SHANGHAI UNITED IMAGING HEALTHCARE

Method of determining communication path in communication network and equipment

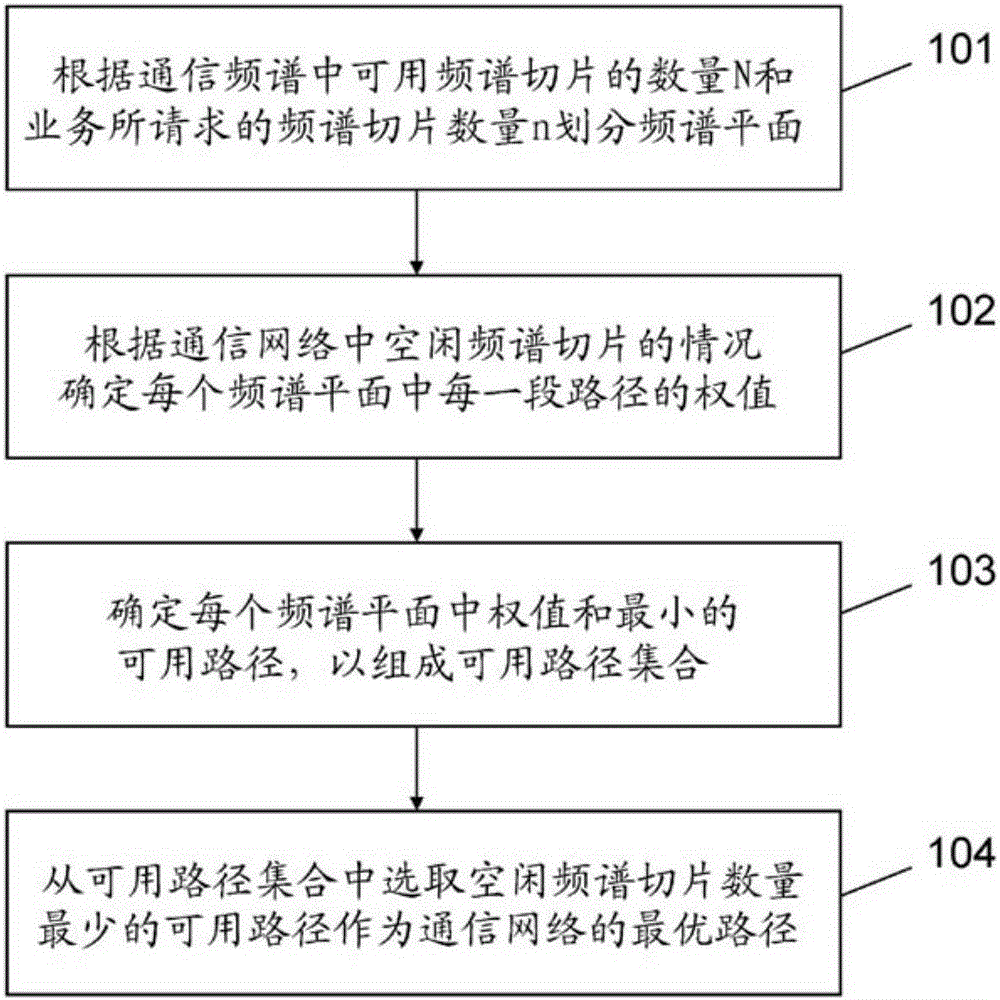

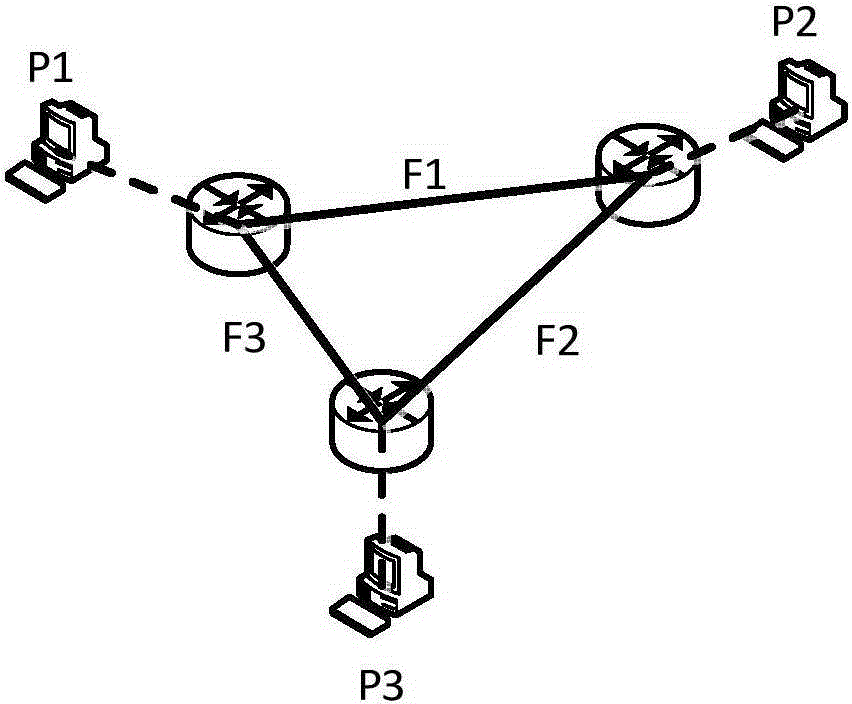

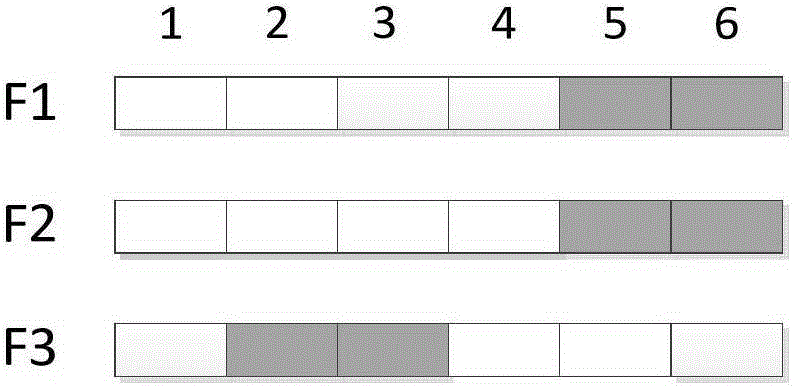

ActiveCN105245307AReduce blocking rateReduce generationWavelength-division multiplex systemsData switching networksFrequency spectrumDistributed computing

The embodiment of the invention discloses a method of determining a communication path in a communication network and equipment. The method comprises steps: spectrum planes are divided according to the number N of available spectrum slices in a communication spectrum and the number n of spectrum slices requested by service; according to conditions of idle spectrum slices in the communication network, a weight of each path section in each spectrum plane is determined; an available path with the minimal weight sum in each spectrum plane is determined to form an available path set; and the available path with the minimal idle spectrum slice number is selected in the available path set to serve as the optimal path in the communication network. On the premise of not influencing or interrupting original service, the path and spectrum resources which minimally influence the network are selected, the blocking rate of a subsequent routing request is reduced, and consistency and the utilization ratio of a single spectrum slice are improved.

Owner:BEIJING UNIV OF POSTS & TELECOMM

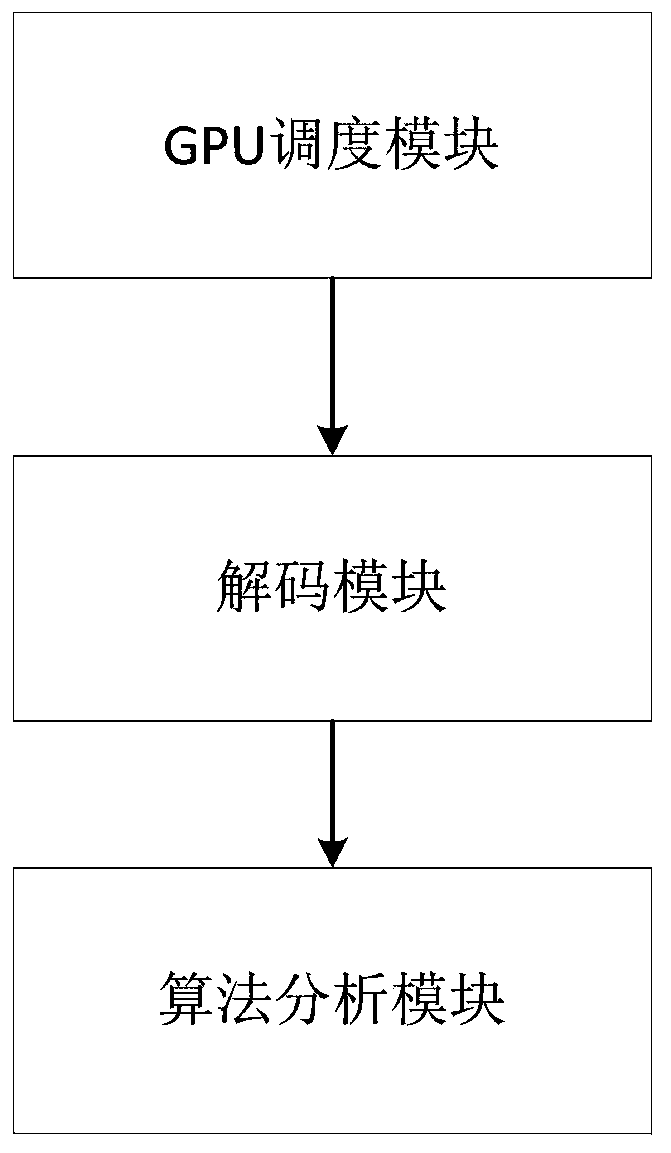

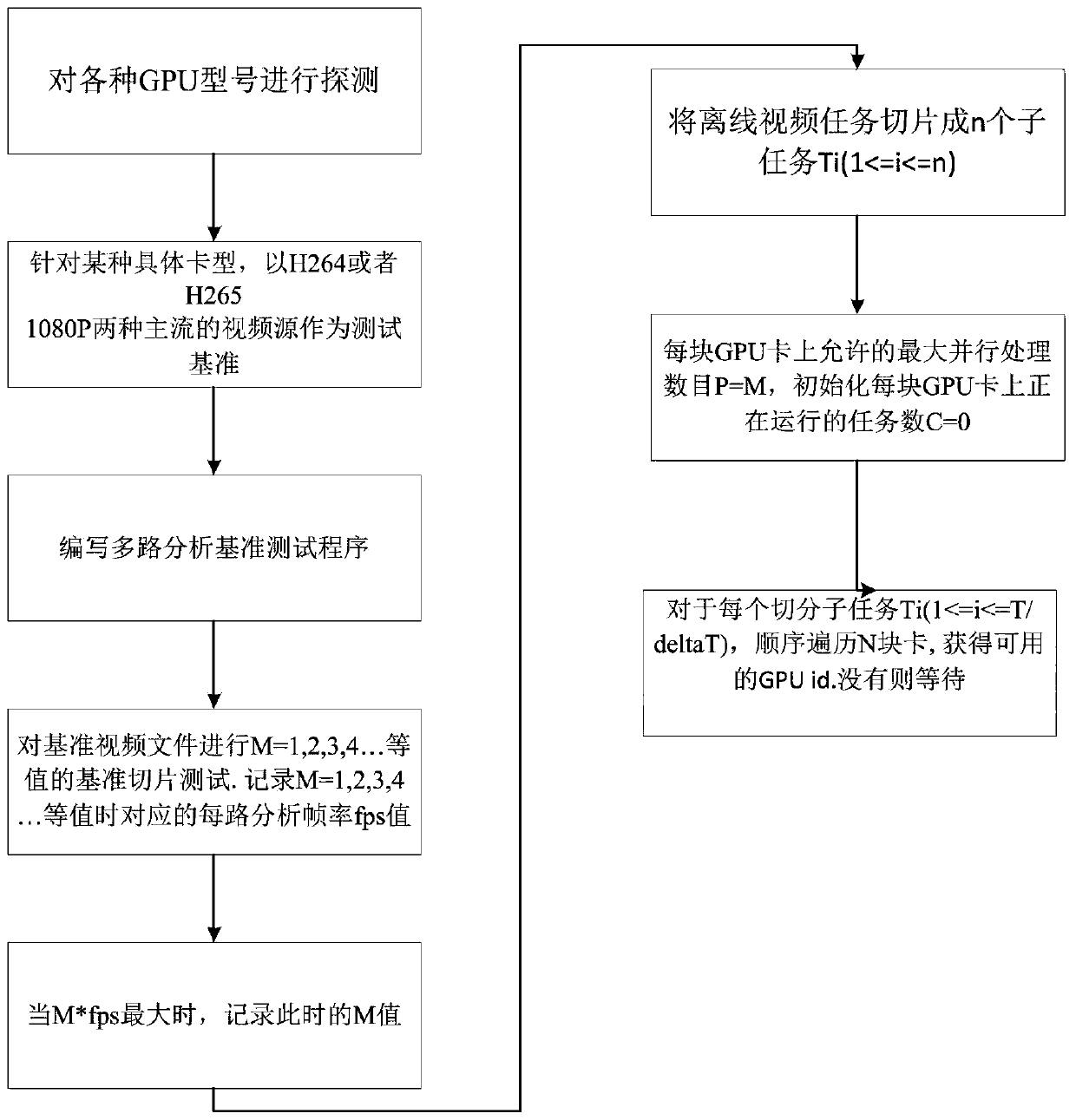

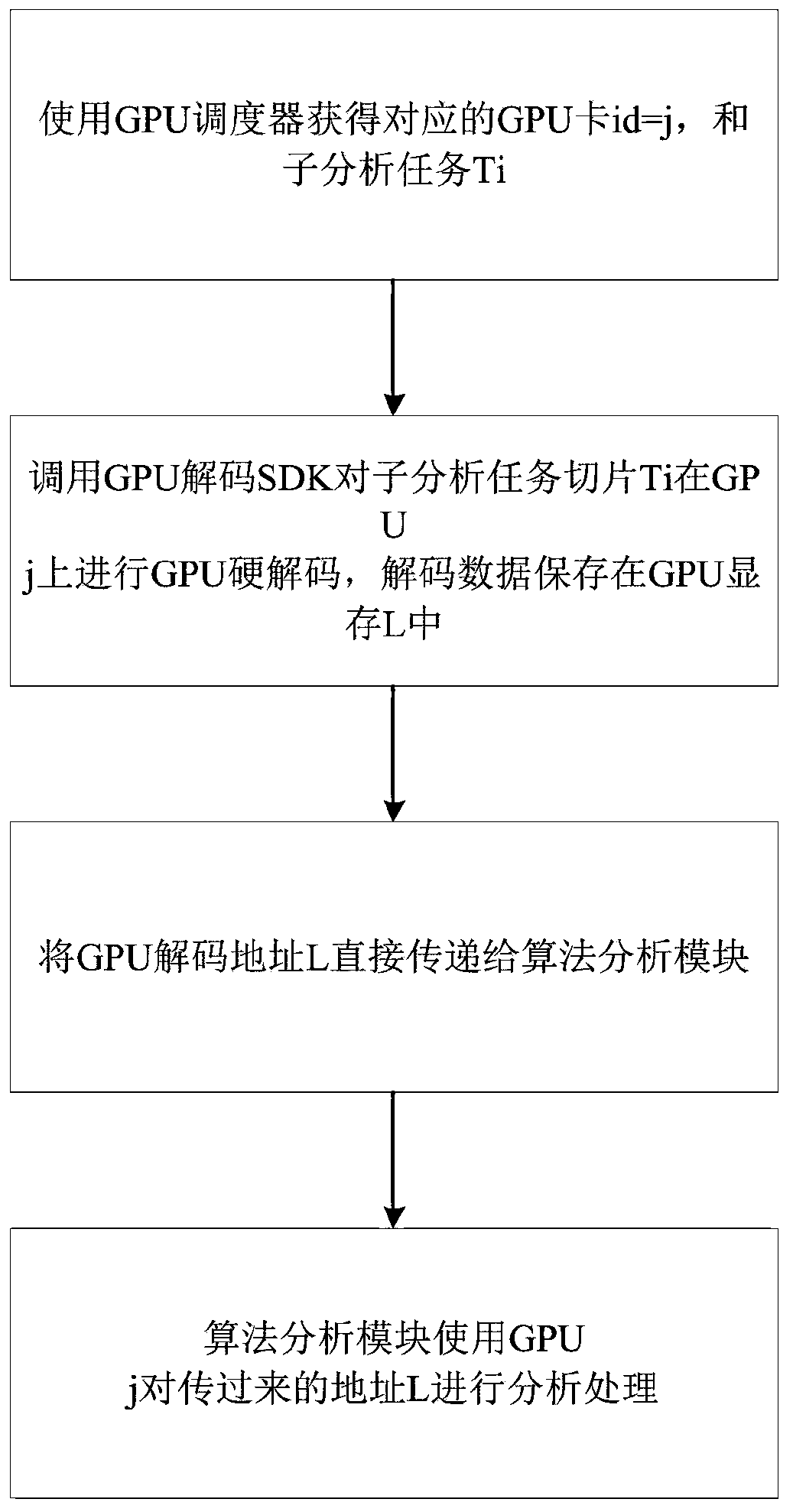

Method, device and equipment for optimizing intelligent video analysis performance

ActiveCN109769115ALower latencyImprove system performanceTelevision systemsDigital video signal modificationVideo memoryBatch processing

The invention relates to a method, a device and equipment for optimizing the analysis performance of an intelligent video, and the method comprises the steps: (1) carrying out a reference piperine test on a video file for the acceleration of an offline video file, and setting an optimal file slice number; slicing the video file, and issuing a slicing task to the GPU; calling a GPU to decode the slice file, and calling back a decoding result to an algorithm directly through a video memory address, and reducing the performance loss without the video memory-main memory copy, wherein the video analysis algorithm takes the decoded video memory address, calls a GPU for algorithm acceleration and outputs an analysis result; (2) optimizing and expanding the number of paths for real-time video stream algorithm analysis; and calling the GPU to decode each path of real-time video, calling back a decoding result to the algorithm directly through a video memory address, setting double caches by analgorithm end, storing decoded data in multiple paths, transmitting the decoded data to the algorithm for GPU batch processing, and switching the two cache functions after batch processing is completed to achieve the purpose of minimum system delay.

Owner:武汉众智数字技术有限公司

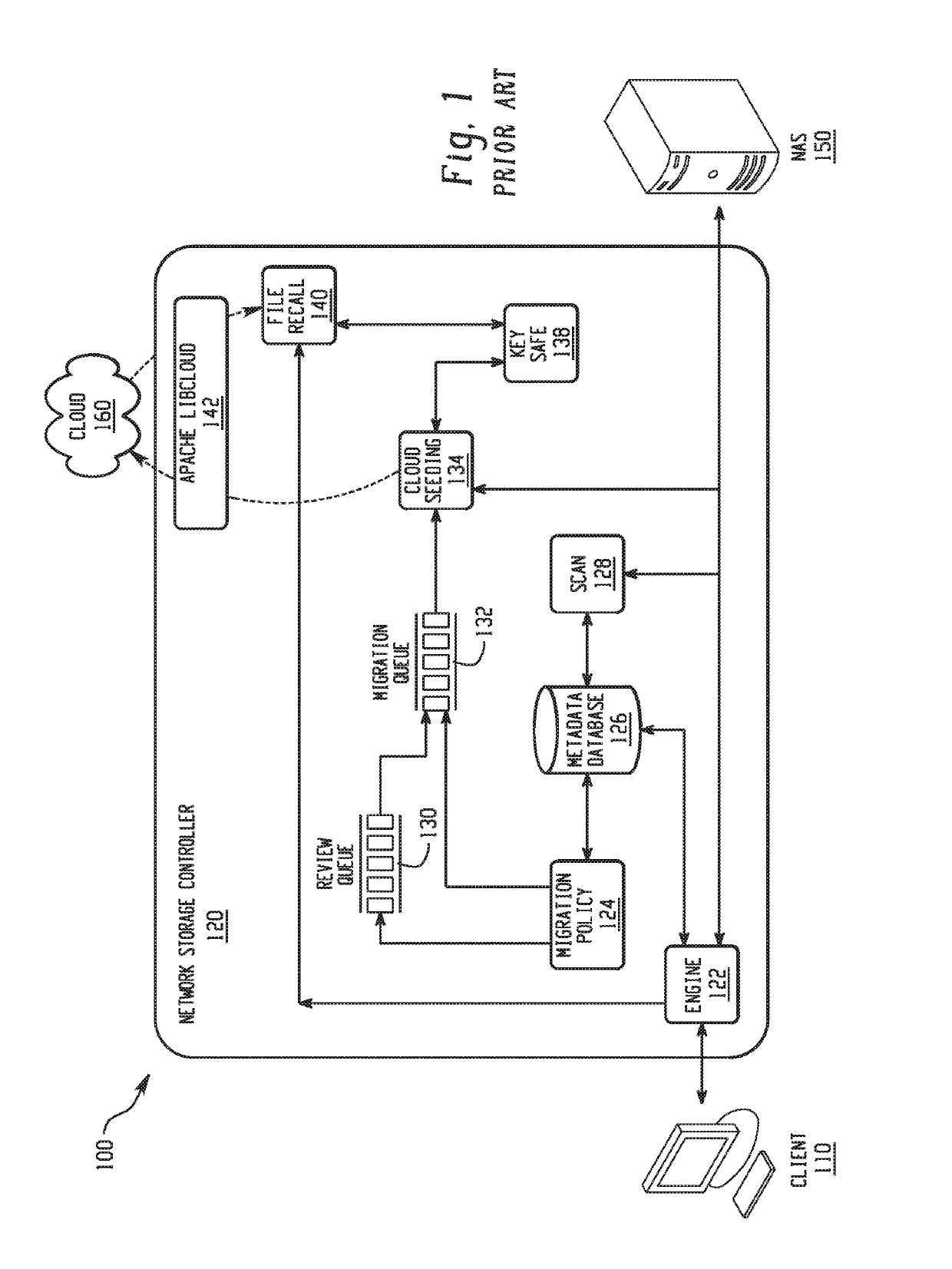

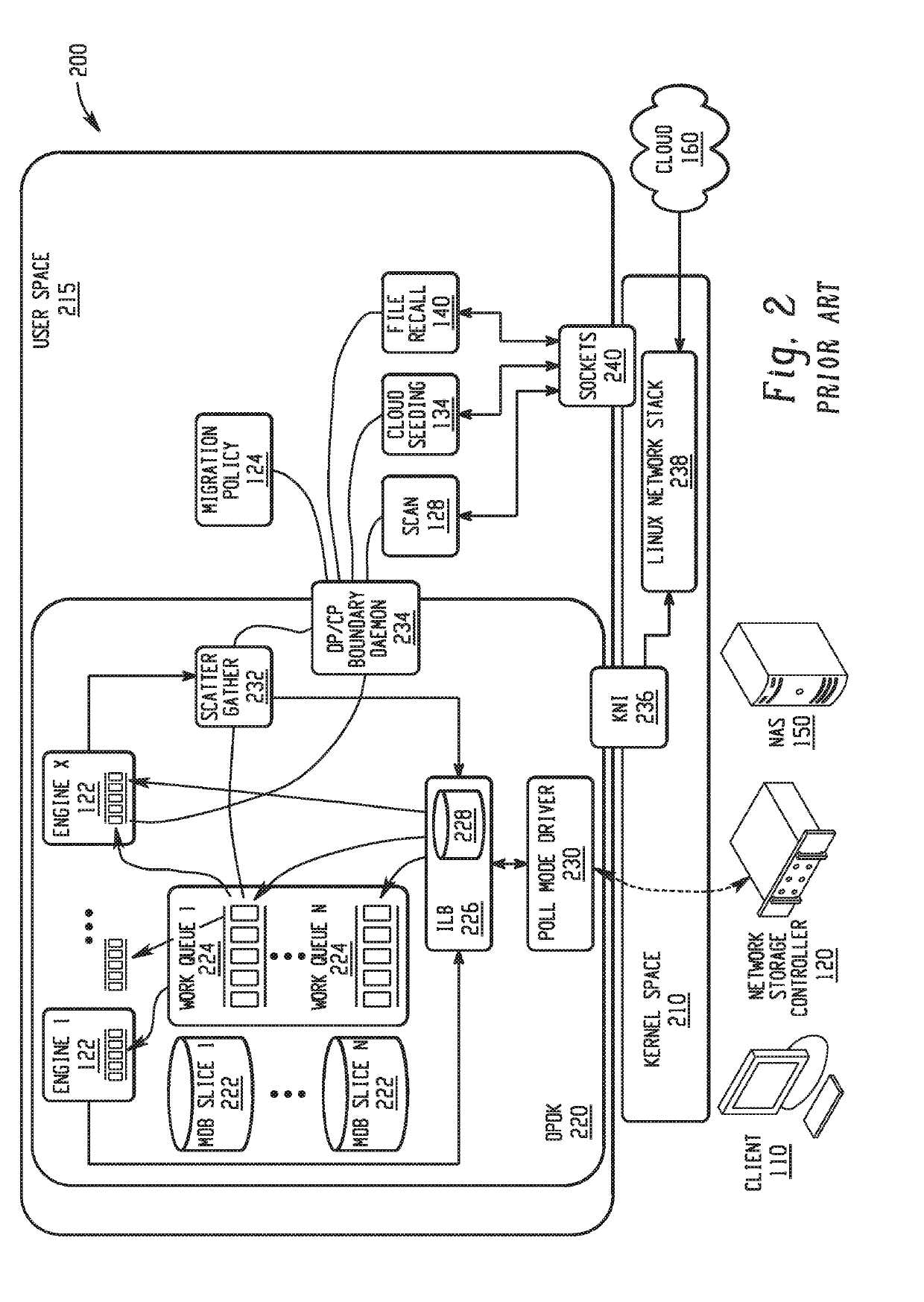

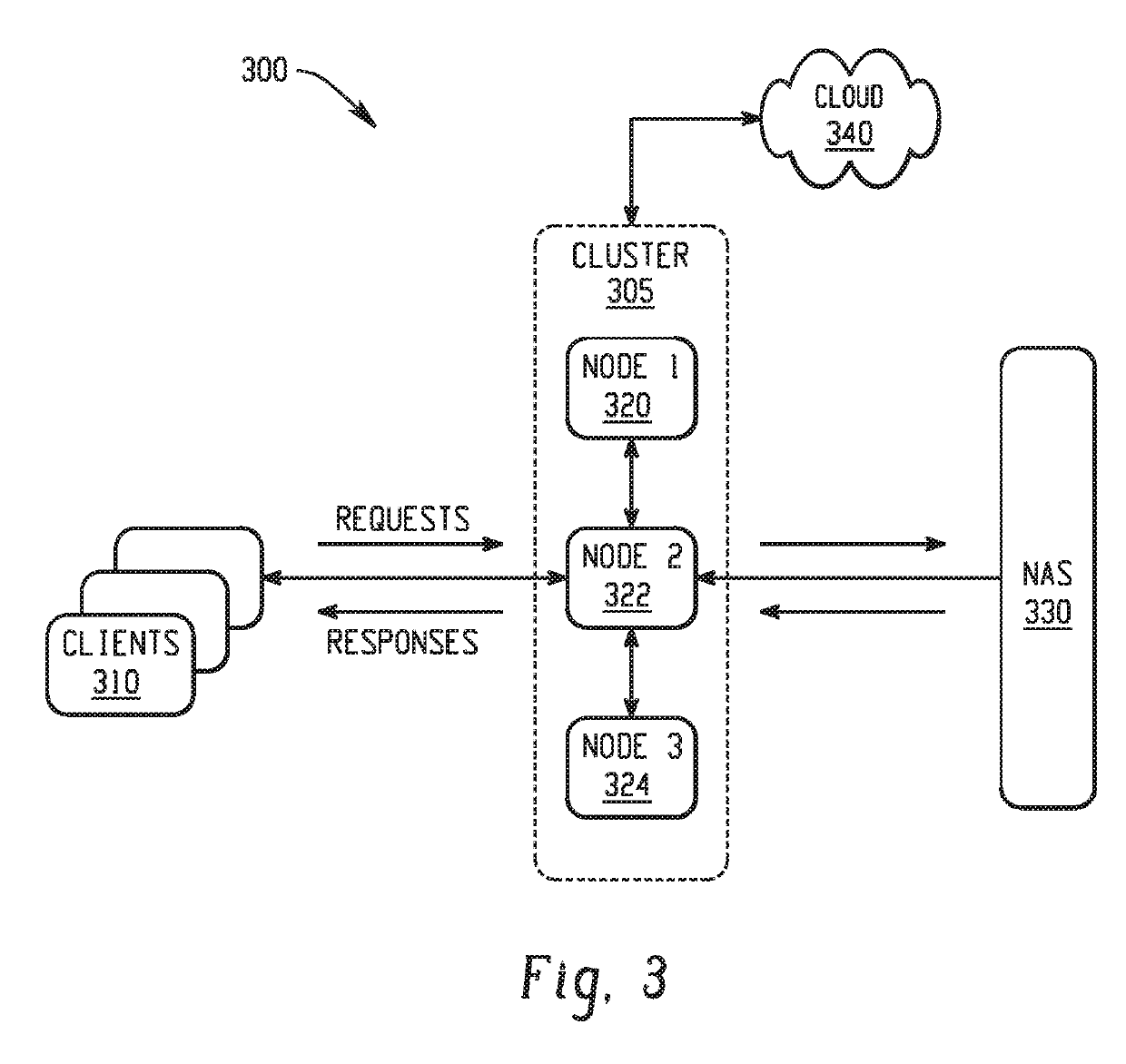

Metadata call offloading in a networked, clustered, hybrid storage system

InactiveUS20190278746A1Database distribution/replicationFile access structuresRouting tableHybrid storage system

Systems, methods, and non-transitory computer readable media for storing and processing metadata corresponding to files are presented. The system comprises first, second, and third computing nodes. The computing nodes comprise a plurality of slices of a metadata database that is separate and independent from file storage, and each slice is configured to store metadata. The computing nodes further comprise a slice route table that indicates primary and secondary locations of each unique slice in the plurality of slices. The slice route table comprises a plurality of entries, each of which comprise a slice number corresponding to a slice in the plurality of slices of the metadata database, a primary computing node number corresponding to a primary computing node that comprises the slice and corresponds to the primary location, and a secondary computing node number corresponding to a secondary computing node that comprises the slice and corresponds to the secondary location.

Owner:INFINITE IO INC

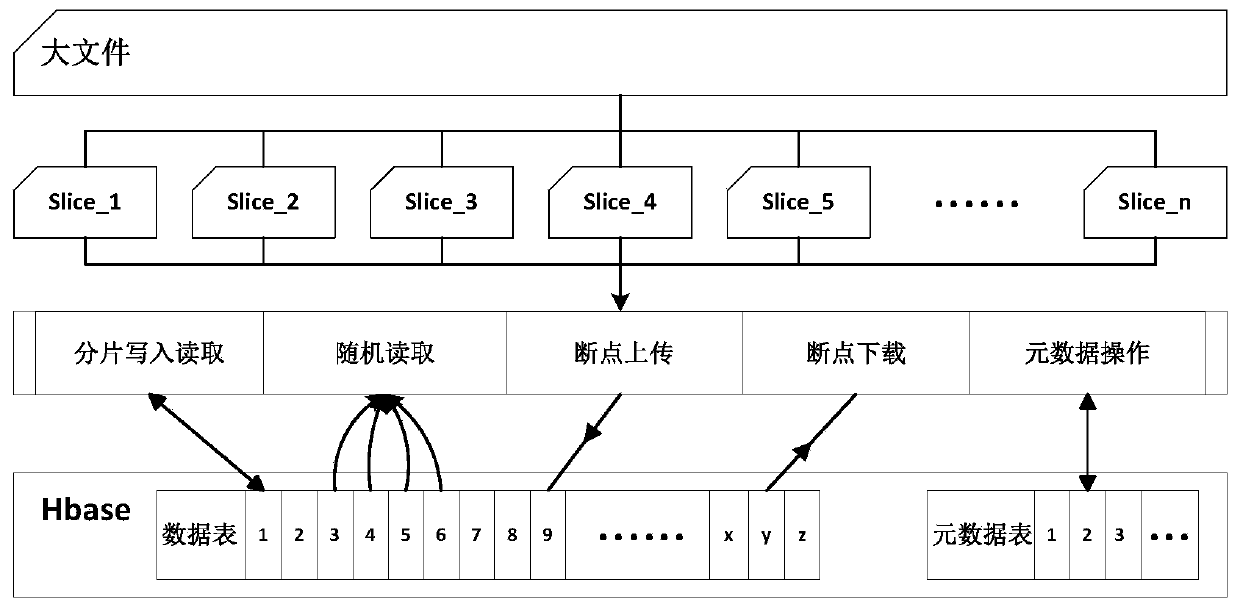

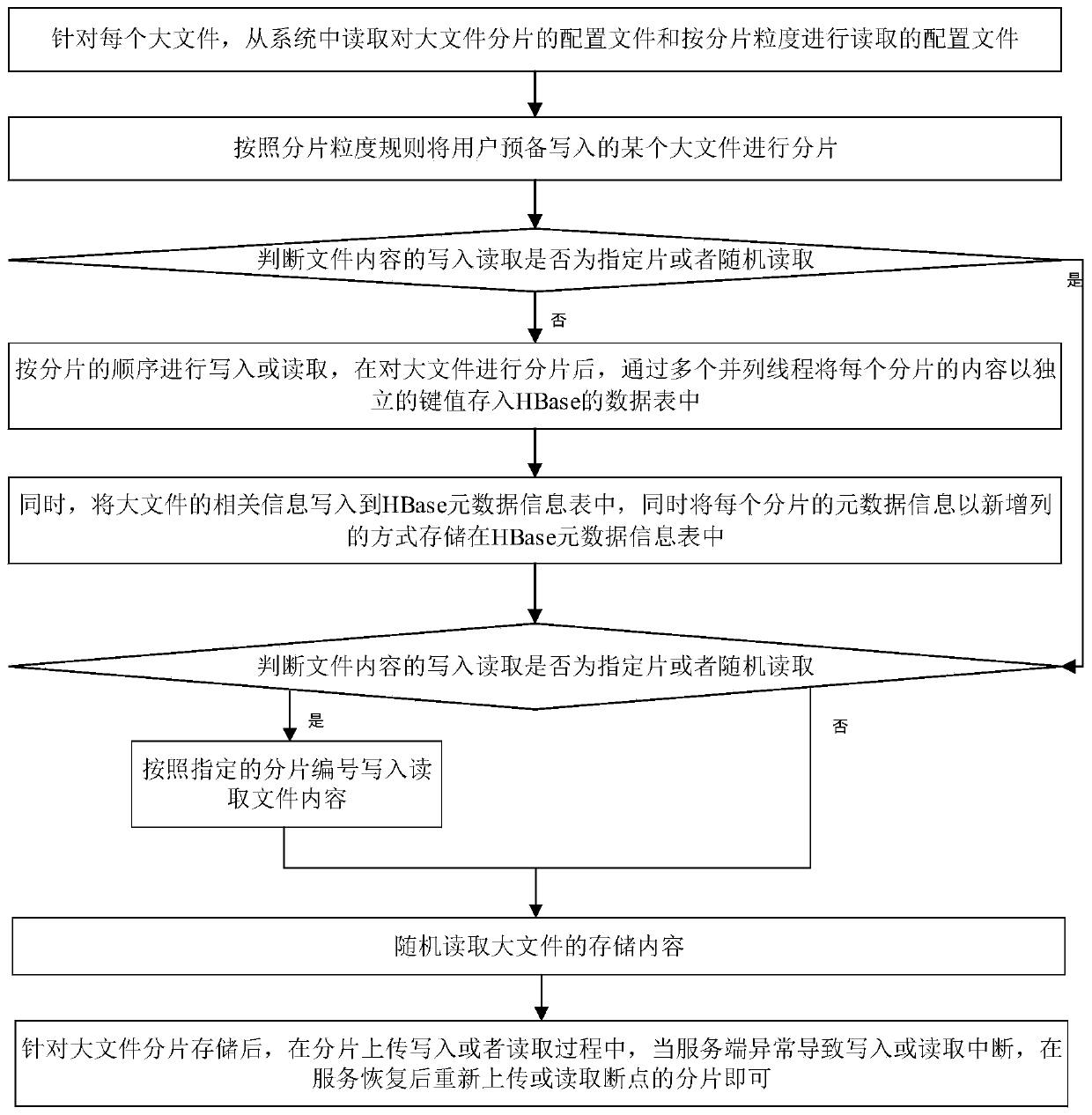

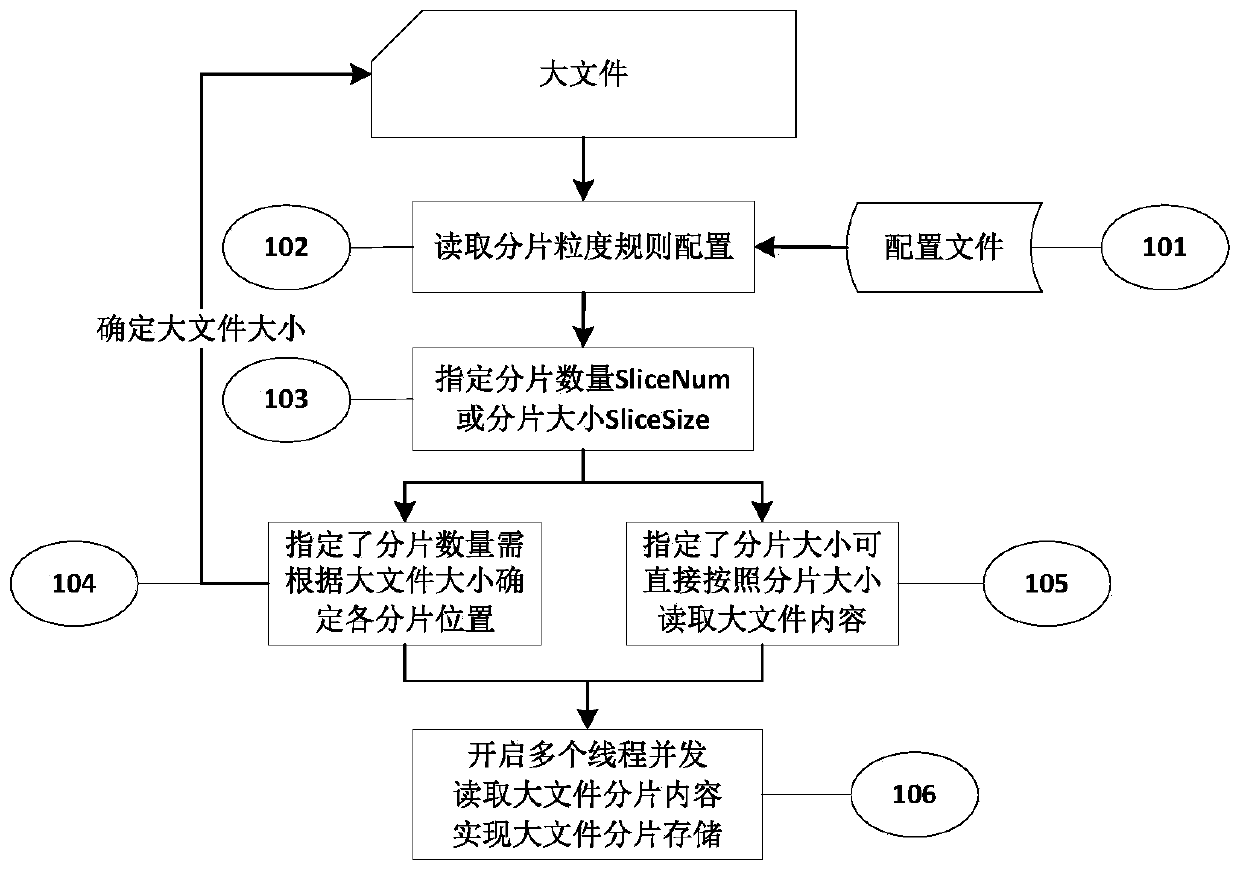

A file fragmentation method based on HBase

ActiveCN109710572AEfficient and reliable storagePracticalFile access structuresFile/folder operationsMetadataSlice Number

The invention discloses a file fragmentation method based on HBase, and belongs to the field of computers. The method comprises the following steps: firstly, reading a configuration file for fragmenting a large file and a configuration file read according to fragmentation granularity from a system, and fragmenting a certain large file; and writing and reading the file content according to the sequence of the fragments, and storing the content of each fragment in the HBase data table in an independent key value mode through a plurality of parallel threads. And meanwhile, storing the metadata information of each fragment in an HBase metadata information table in a newly added column manner. If the writing and reading of the file content is the specified slice, writing and reading the file content according to the specified slice number; if the write-in reading of the file content is random reading, setting a byte starting position and a read content size of the random reading; and finally, when the server is abnormal to cause writing or reading interruption, uploading or reading the fragment of the breakpoint again after the service is recovered. According to the method, the large file storage is more efficient and reliable, and the practicability and the adaptability are higher.

Owner:BEIJING SCISTOR TECH

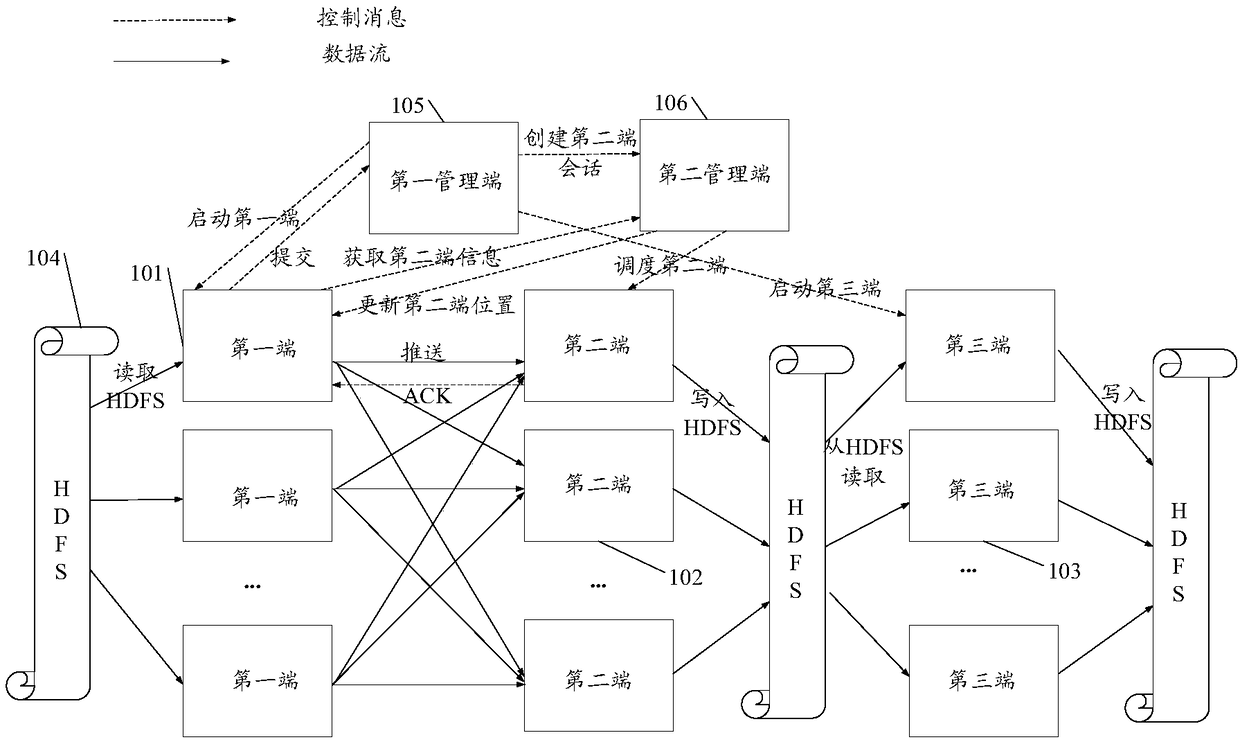

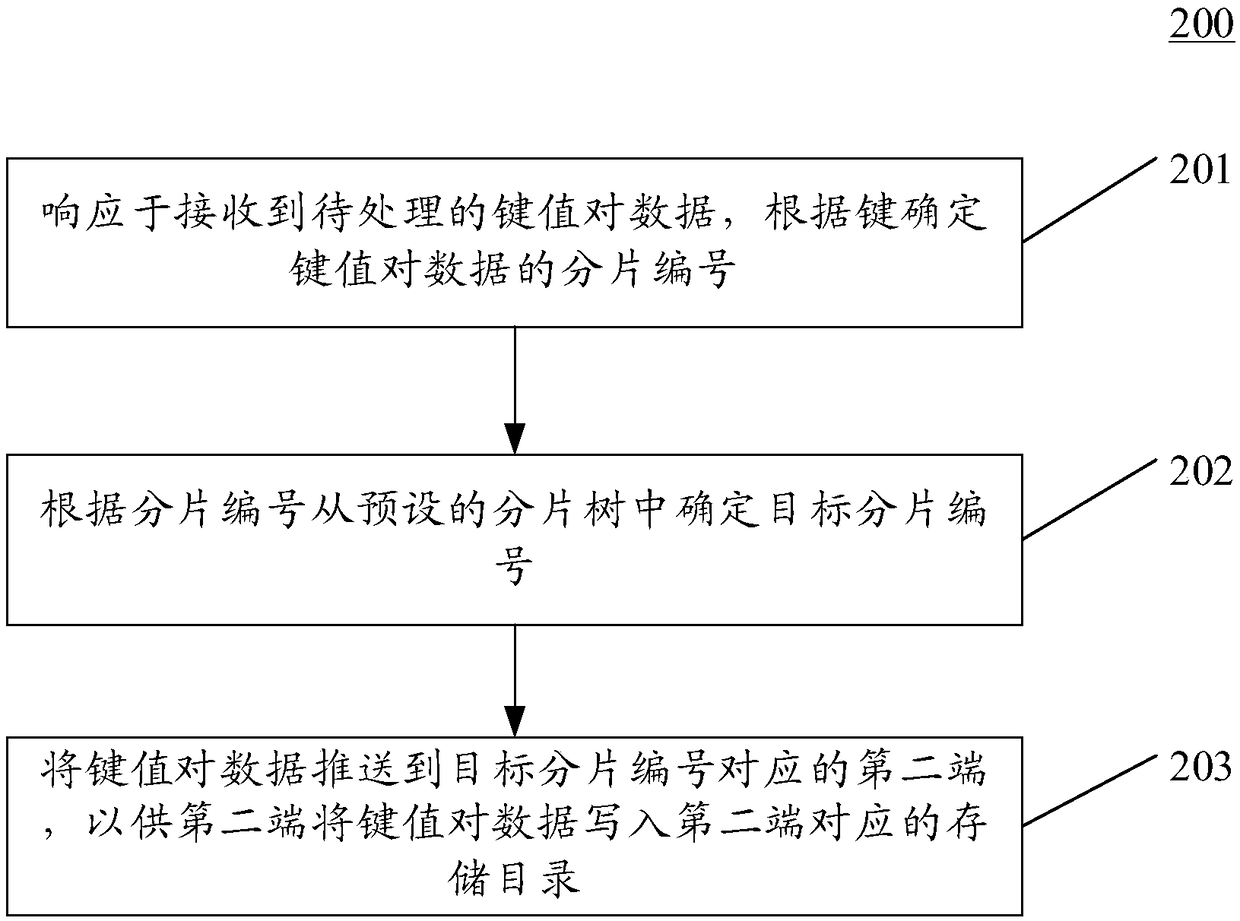

Method, apparatus and system for processing data

ActiveCN109508326AFix too smallImprove data processing capabilitiesDigital data information retrievalResource allocationPaired DataBinary tree

A method, apparatus and system for processing data are disclosed in embodiment of that present application. One embodiment of the method includes determining a slice number of key-value pair data based on a key in response to receiving key-value pair data to be processed. A target slice numb is determined from a preset slice tree accord to that slice number, wherein the slice tree is a binary treestructure, the node represents at least one slice number, and the node corresponds to a storage directory. The key-value pair data is pushed to the second end corresponding to the target slice numberfor the second end to write the key-value pair data to the storage directory corresponding to the second end. This embodiment improves data processing efficiency.

Owner:BEIJING BAIDU NETCOM SCI & TECH CO LTD

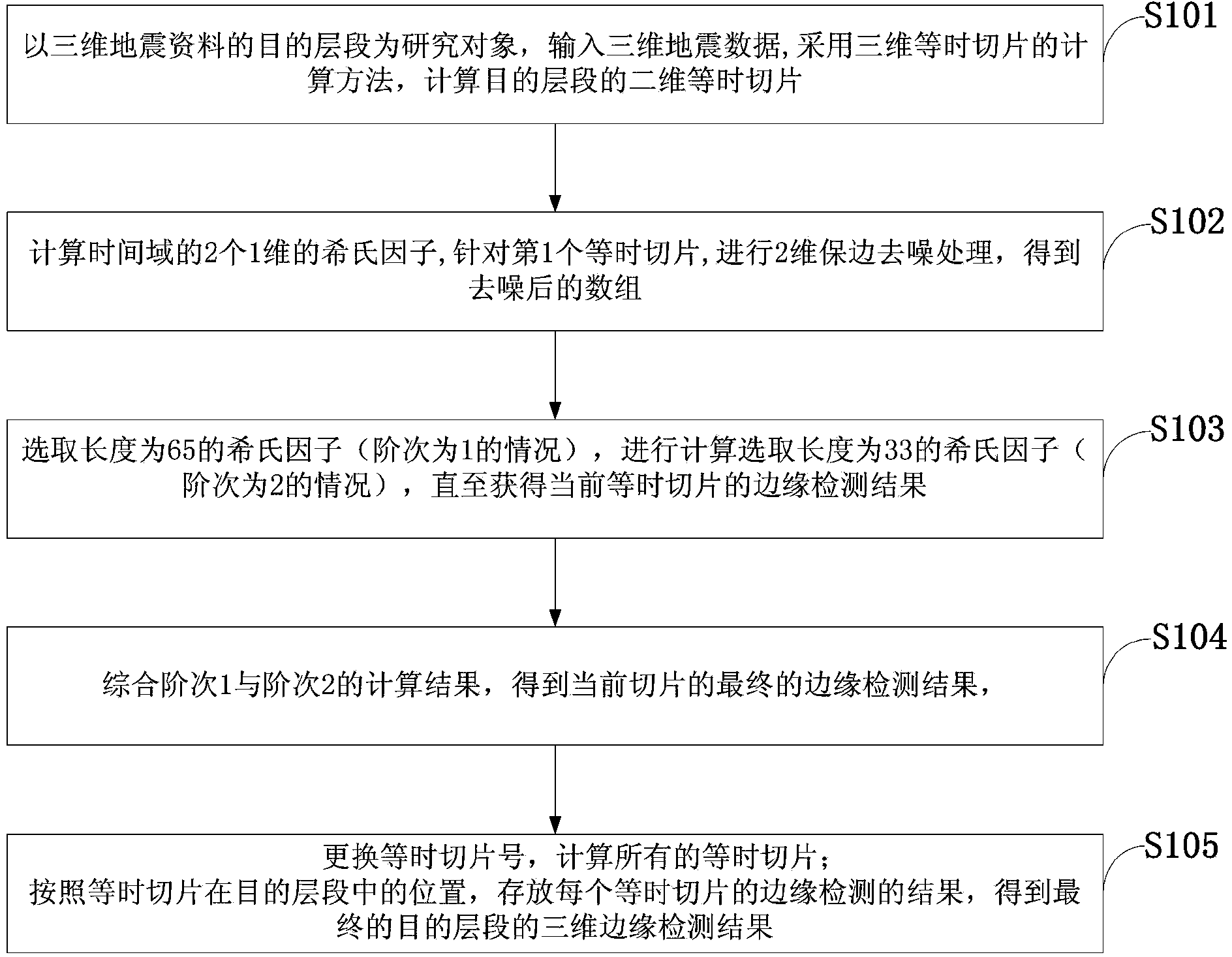

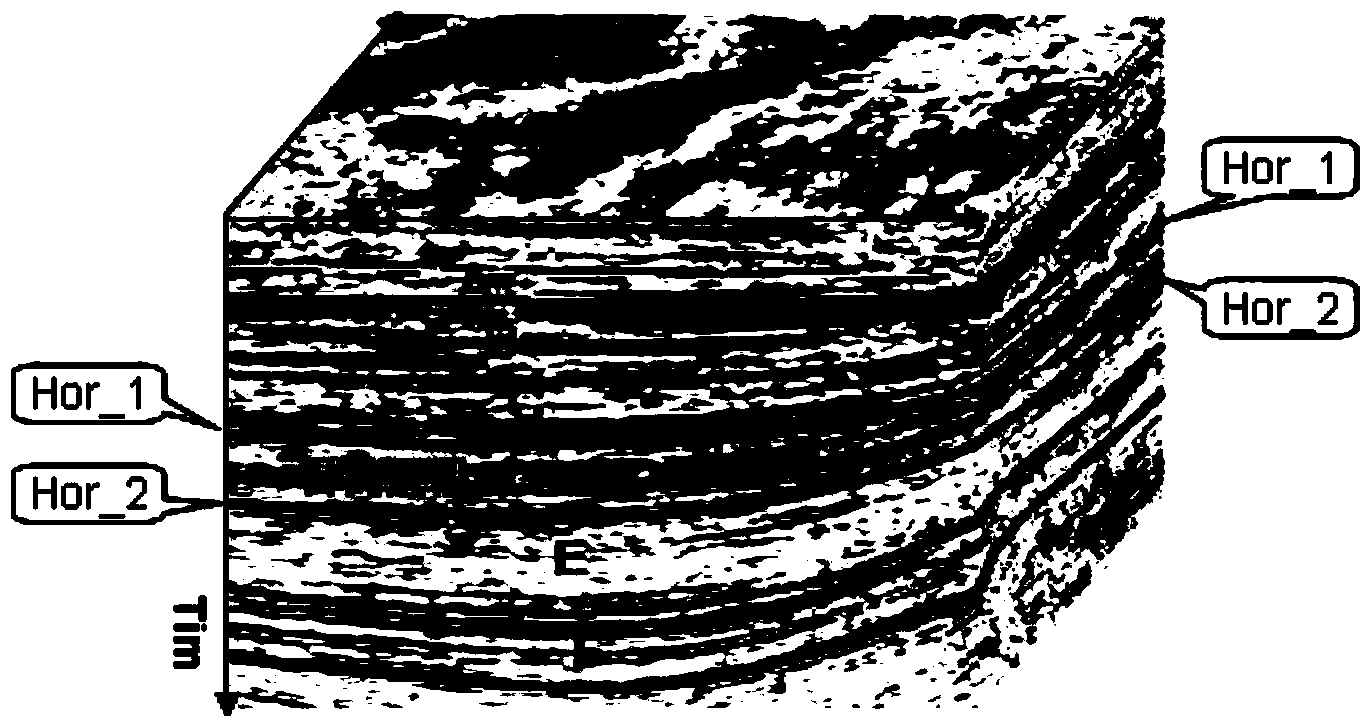

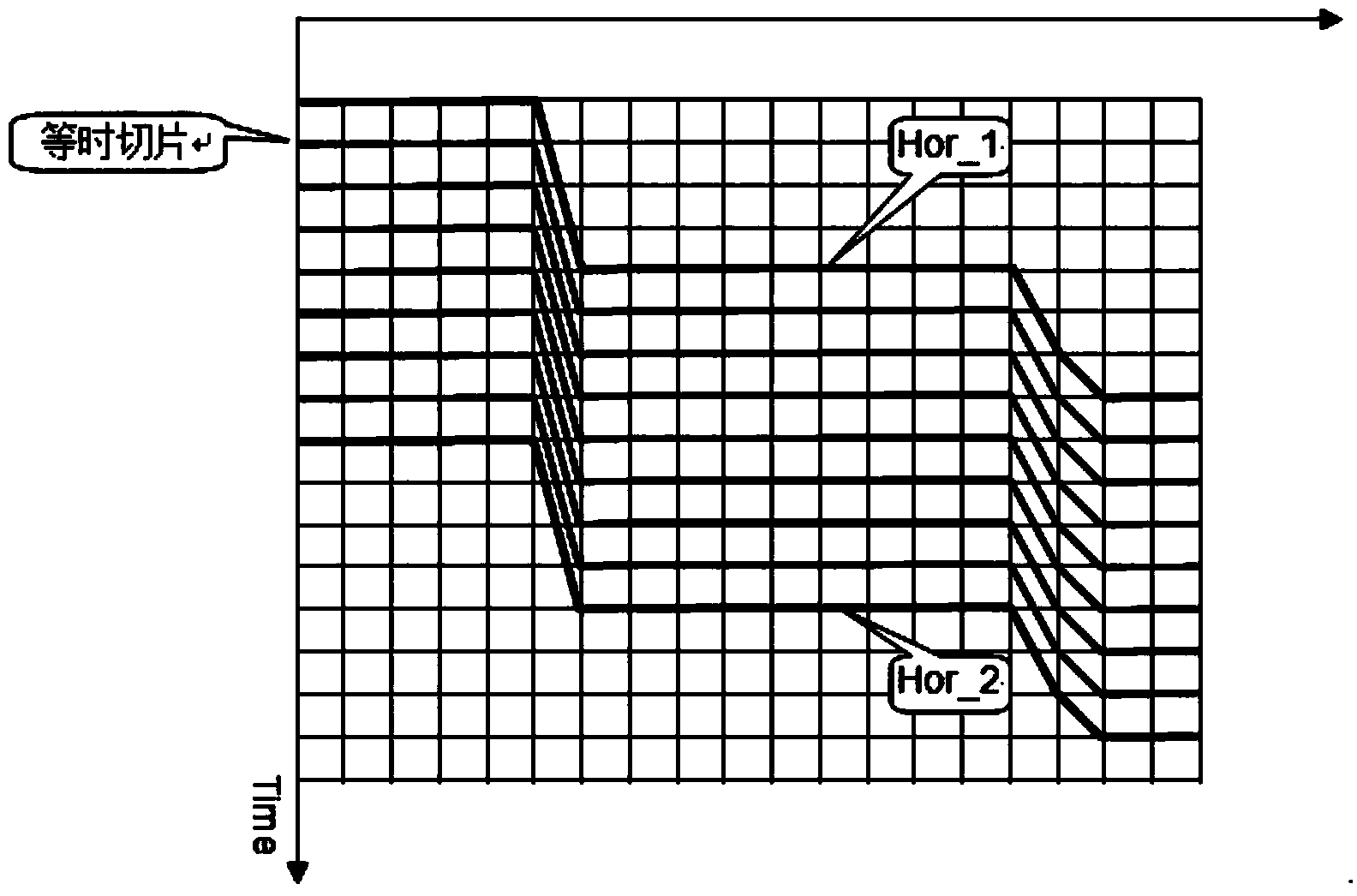

Three-dimensional seismic data quick edge detection method based on time domain generalized Hilbert conversion

InactiveCN103777241APromote reductionHigh precisionSeismic signal processingTime domainResearch Object

The invention discloses a three-dimensional seismic data quick edge detection method based on time domain generalized Hilbert conversion. The method includes the following steps that an objective interval of three-dimensional seismic data serves as a research object, the three-dimensional seismic data are input, a three-dimensional equitime slice calculation method is adopted, and a two-dimensional equitime slice of the objective interval is calculated; two one-dimensional Ehrlich's factors of a time domain are calculated to obtain an edge detection result of the current equitime slice; an ultimate edge detection result of the current slice is obtained; equitime slice numbers are replaced, and all the equitime slices are calculated; according to the positions of the equitime slices in the objective interval, edge detection results of the equitime slices are stored to obtained an ultimate three-dimensional edge detection result of the objective interval. The method has high edge detection accuracy, is high in calculation efficiency and guarantees that all sampling points are located on the respective equitime slices; underground geological conditions closest to reality are obtained, and meanwhile, restoration of the edge detection result is facilitated.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

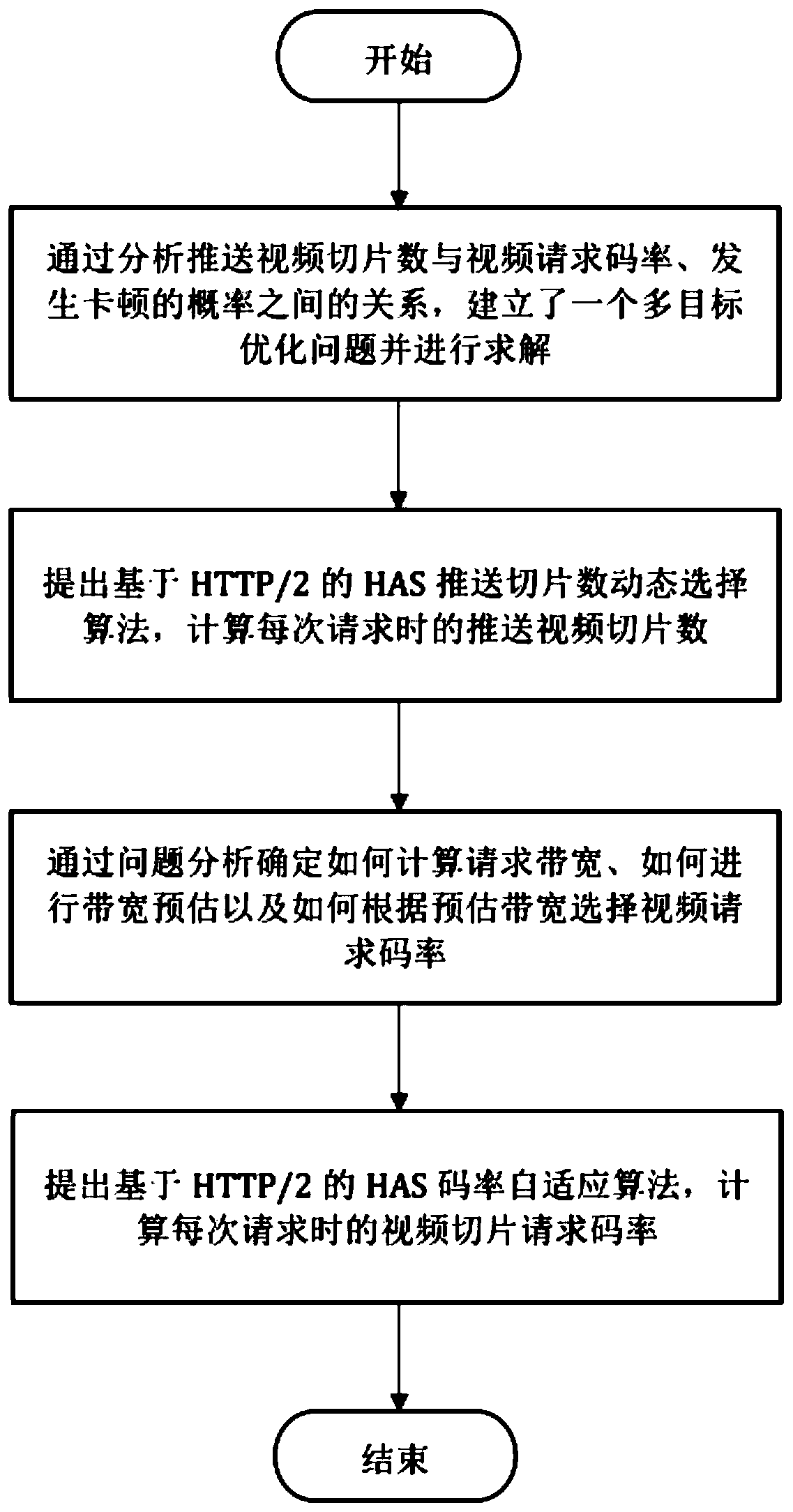

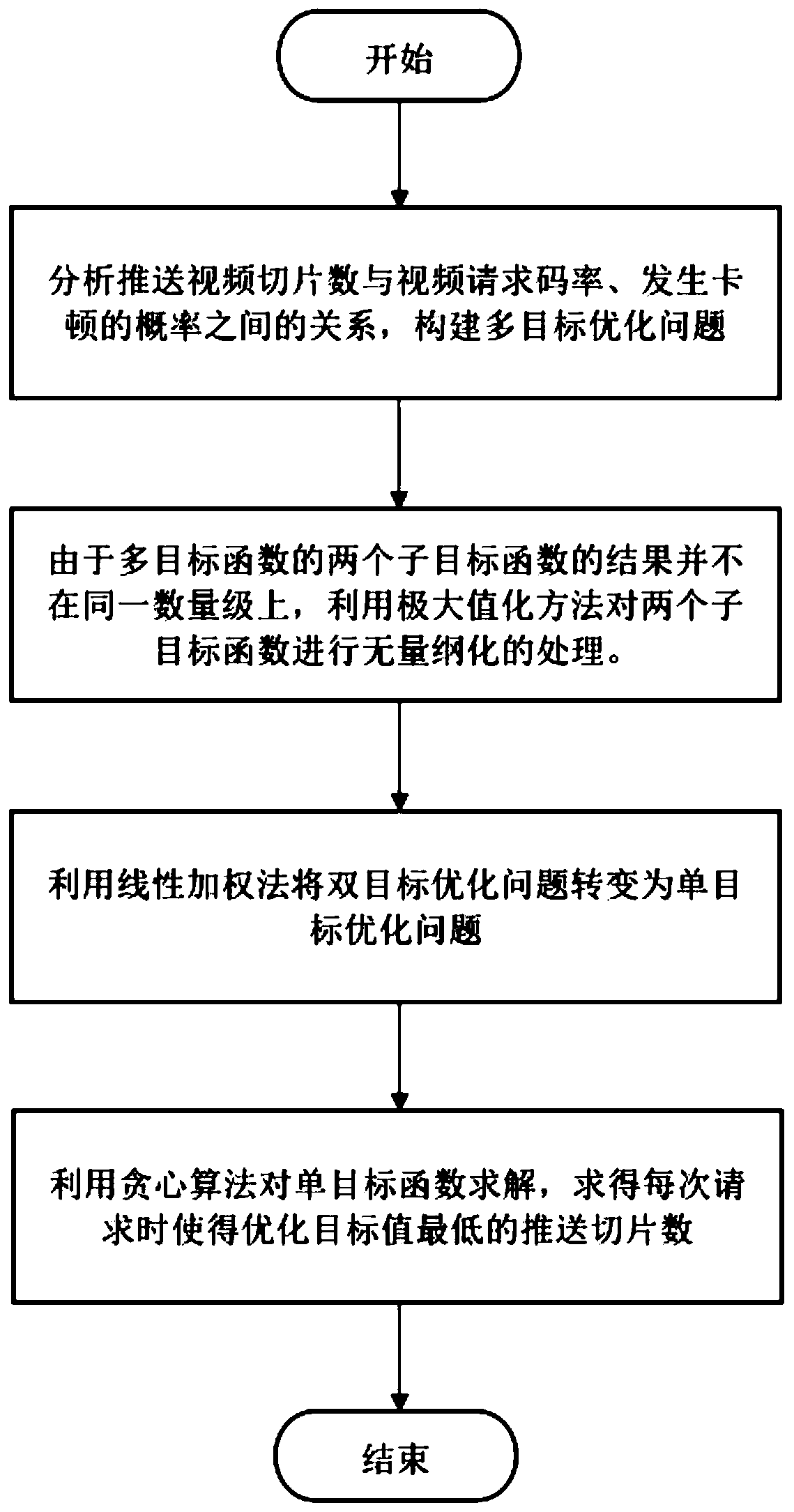

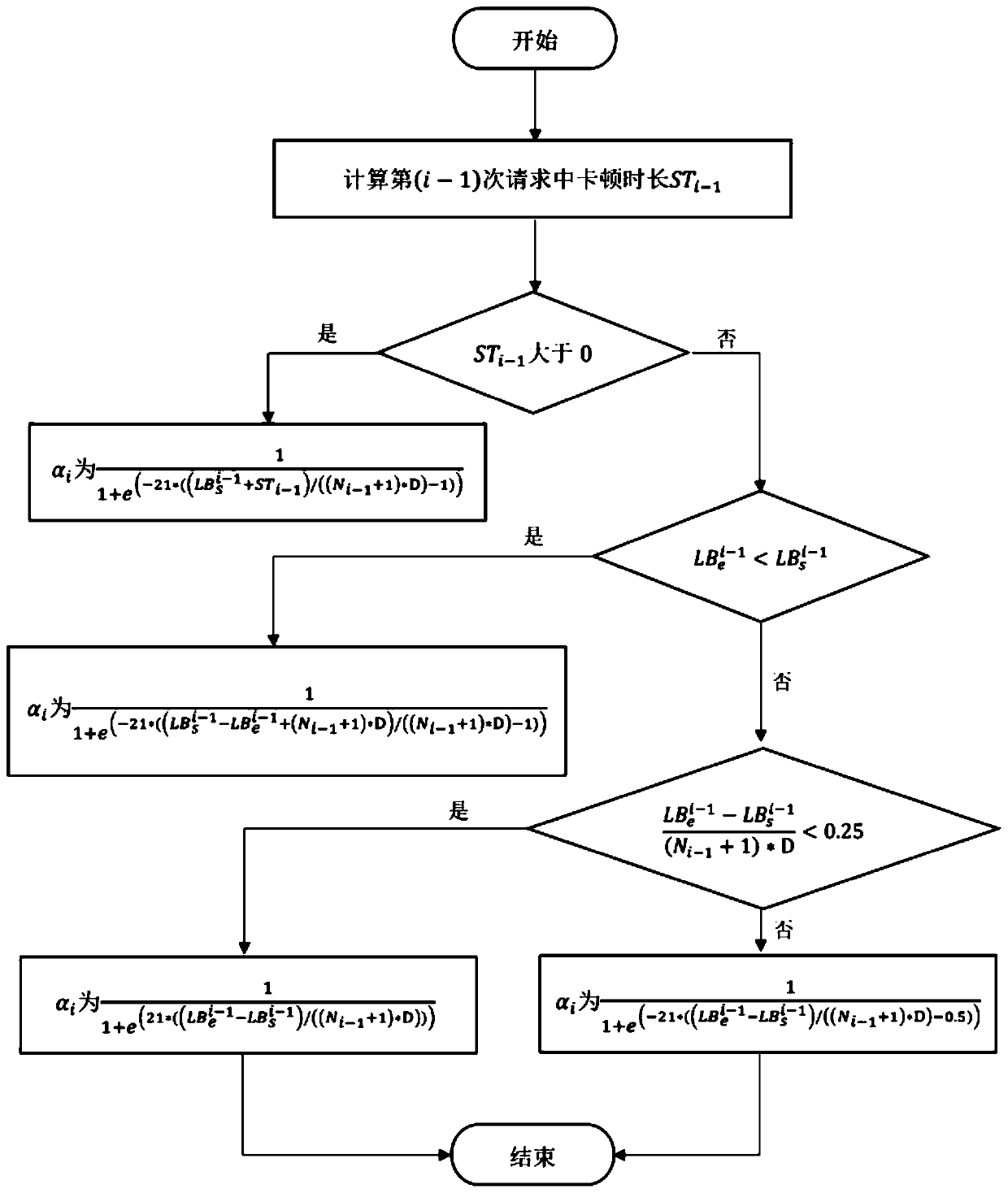

HAS video slice pushing method based on HTTP/2

ActiveCN110072130AImprove viewing experienceFlexible choiceSelective content distributionPattern recognitionSelf adaptive

The invention discloses an HAS (HTTP, Adaptive Streaming) video slice pushing method based on HTTP / 2. The video slice pushing comprises the number of pushed video slices and a video slice request coderate. The method comprises: establishing and solving a multi-objective optimization problem by analyzing the relationship among the number of pushed video slices, the video request code rate and theprobability of jamming; based on this, providing an HAS push slice number dynamic selection algorithm based on HTTP / 2, and calculating the push video slice number in each request; determining how to calculate a request bandwidth, how to perform bandwidth estimation and how to select a video request code rate according to the estimated bandwidth through problem analysis; based on this, providing anHAS code rate adaptive algorithm based on HTTP / 2, and calculating the video slice request code rate in each request.

Owner:XI AN JIAOTONG UNIV +1

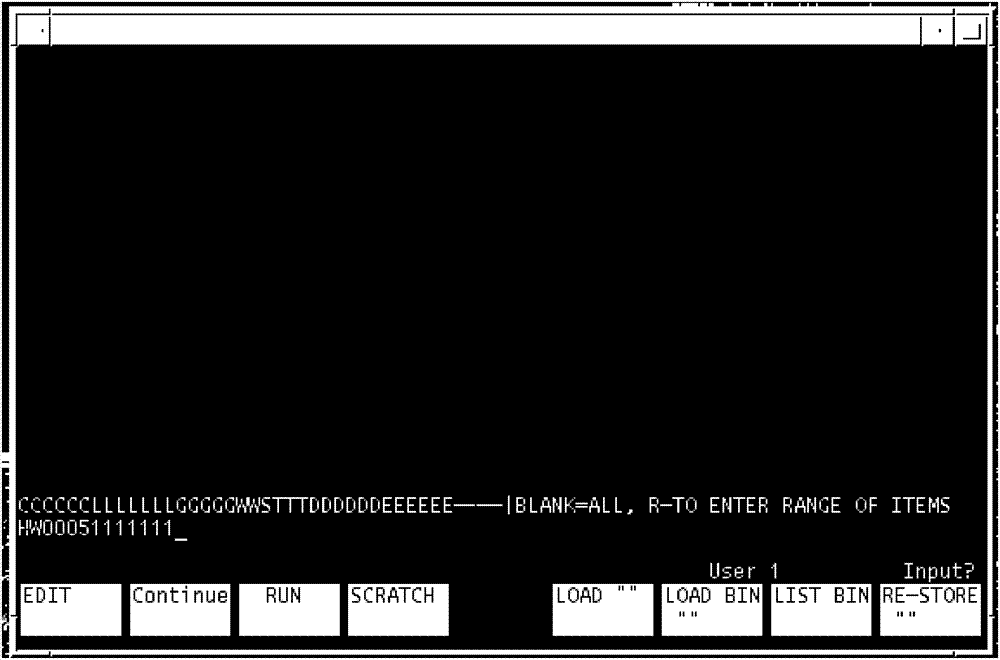

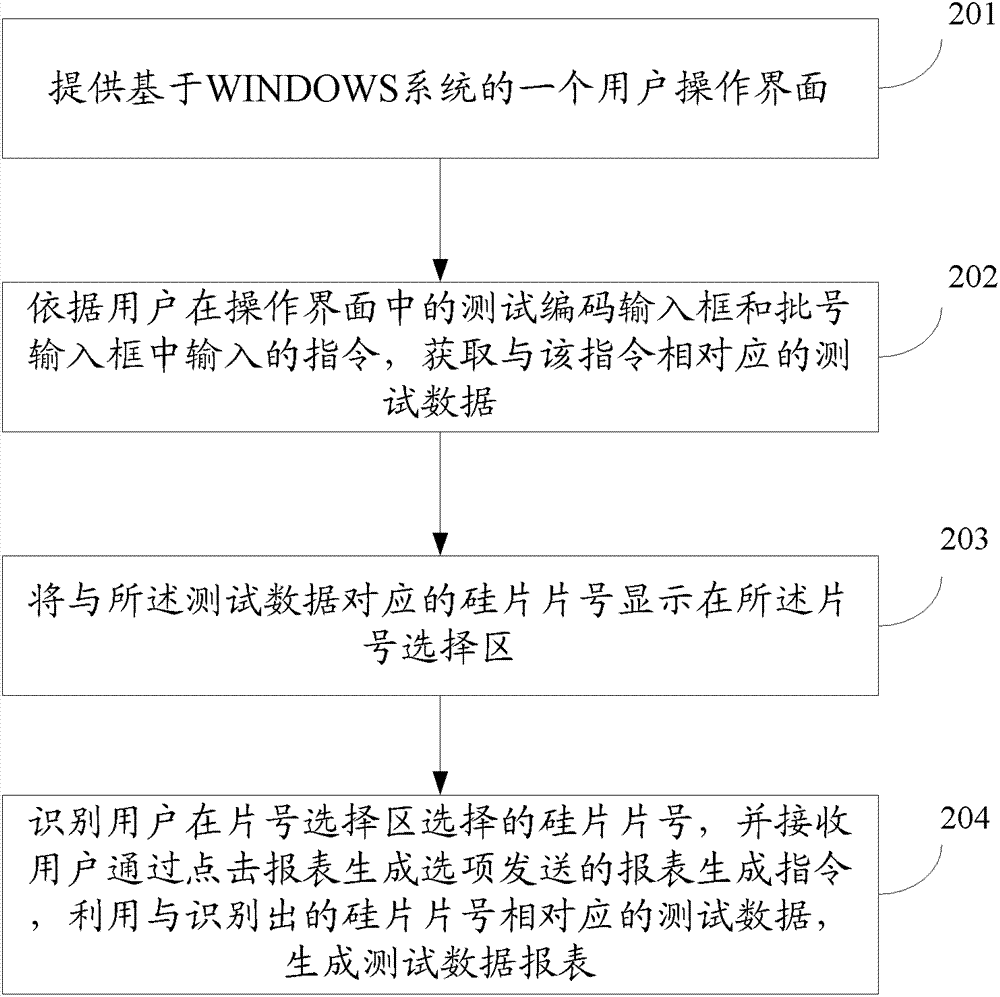

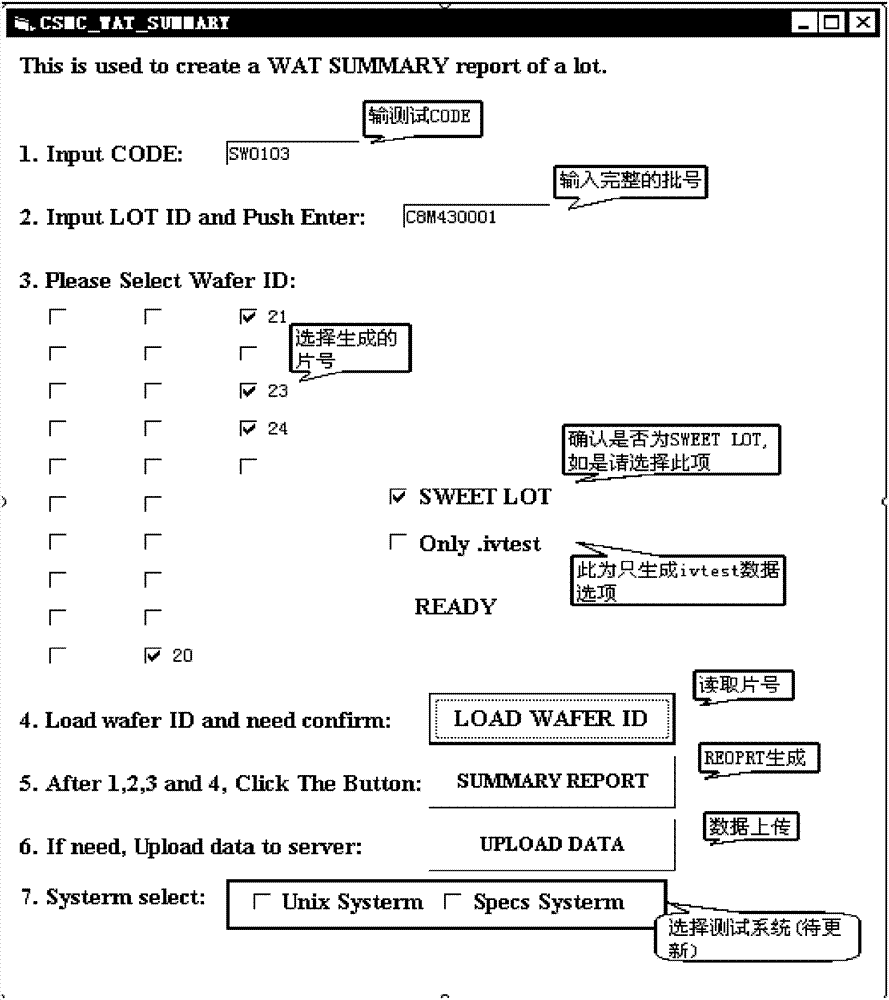

Method and system for generating test data report form

InactiveCN103092864AShort timeReduce orderSpecial data processing applicationsComputer scienceSilicon

The invention discloses a method and a system for generating a test data report form. The method and the system include: providing a user operation interface which is based on a Windows system and comprises a test menu name input box, a batch number input box, a slice number selection area and a report form generating option; obtaining test data corresponding to commands which are input into a test code input box and the batch number input box by a user; displaying a silicon slice number corresponding to the test data on the slice number selection area; and identifying the silicon slice number which is selected from the slice number selection area by the user, receiving a report form generating command sent by the report form generating option when the report form generating option is clicked by the user, and using the test data corresponding to the identified silicon slice number to generate the test data report form. The method for generating the test data report form is simple in operating process, and short in time of generating the test report form, and improves report form generating efficiency.

Owner:CSMC TECH FAB2 CO LTD

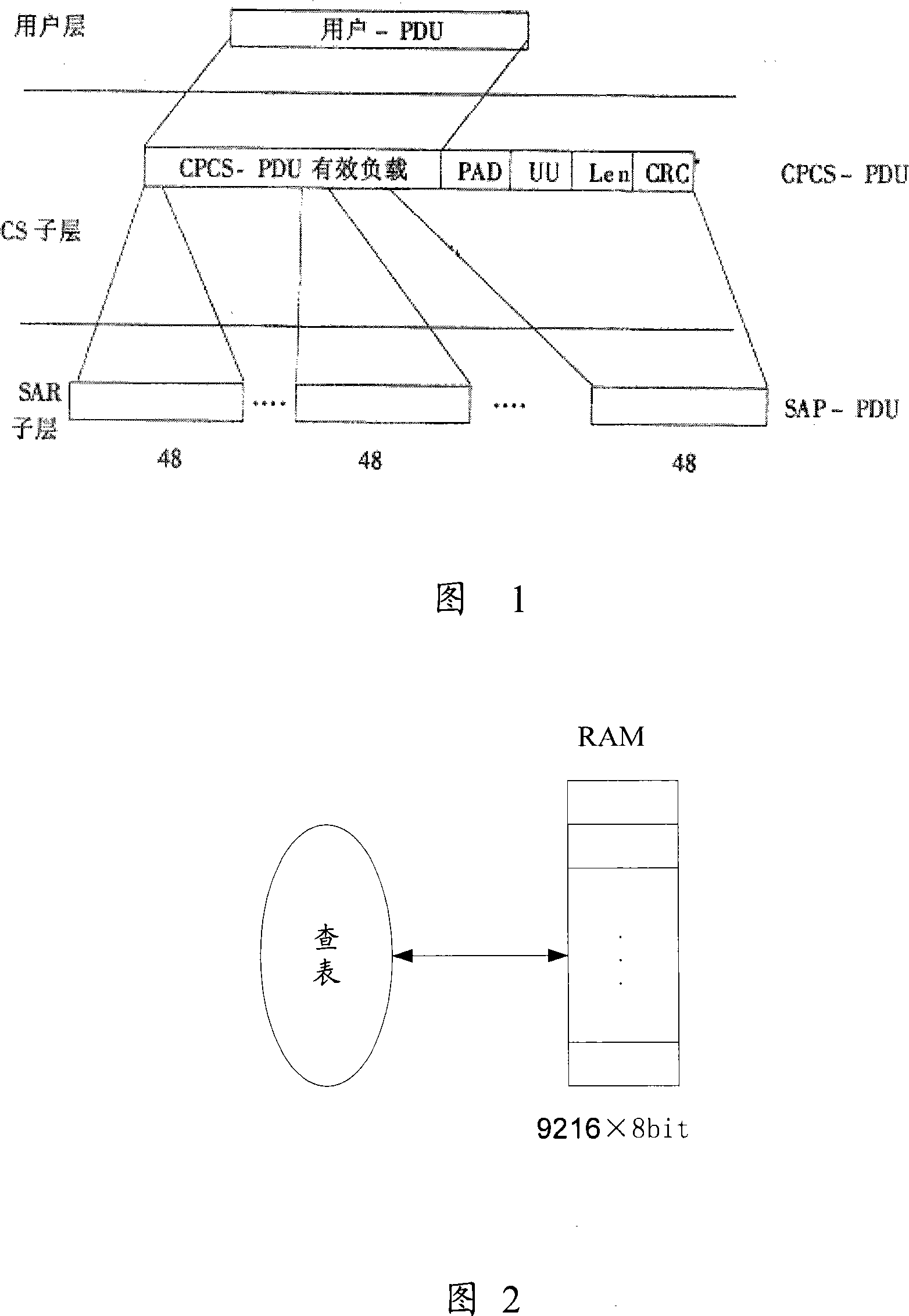

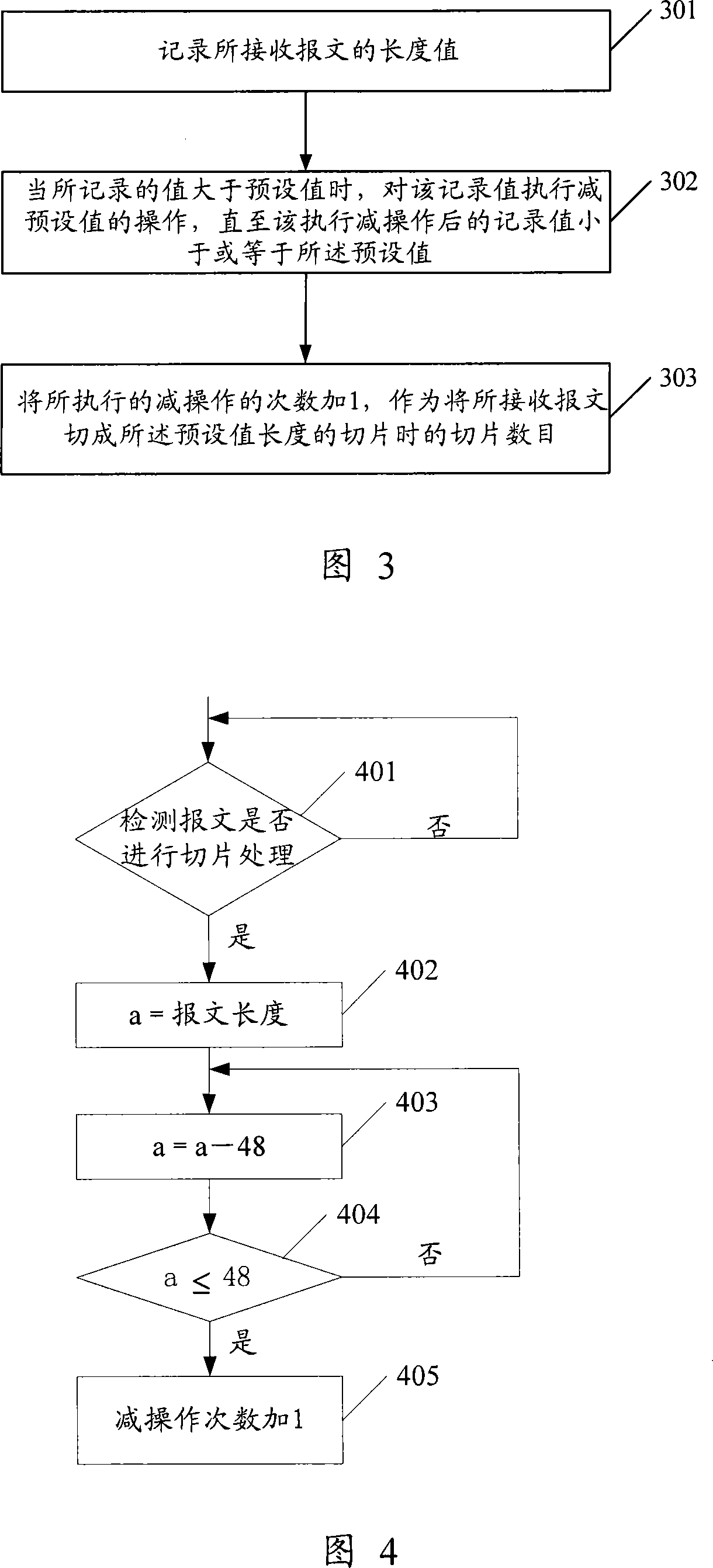

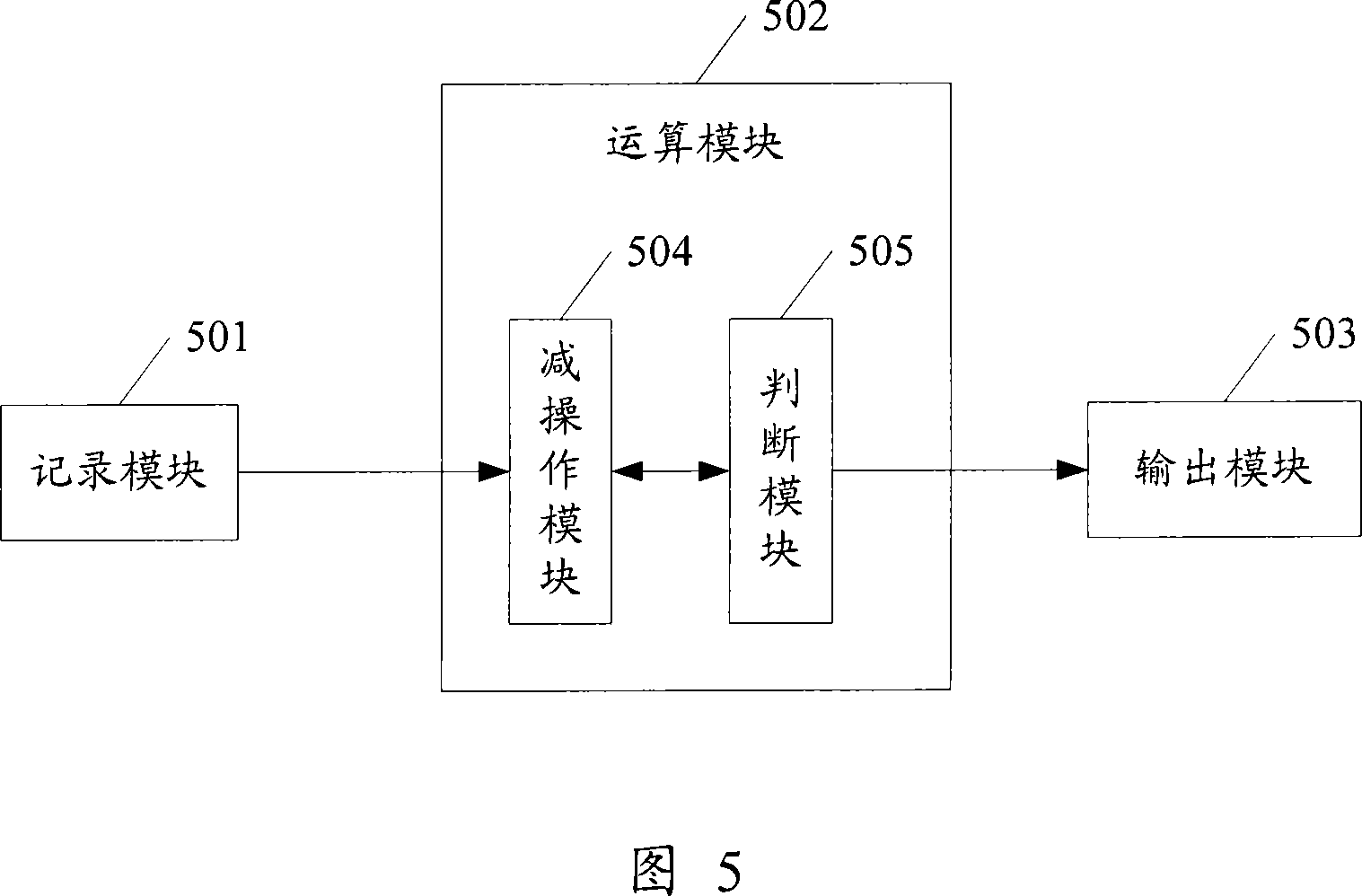

Method and apparatus for obtaining packet slice numbers

The invention discloses a method for obtaining a message fragment number, which comprises recording the length of a received message; when the record value is higher than a preset value, decreasing the preset value to the recoded value until the record value is lower than the preset value; and adding the number of decrement operation by 1 to obtain the fragment number when cutting the received message to fragments with preset length. The invention also discloses a device for obtaining message fragment number. The invention can obtain message fragment number without consuming a large amount of random access memory (RAM) resource.

Owner:NEW H3C TECH CO LTD

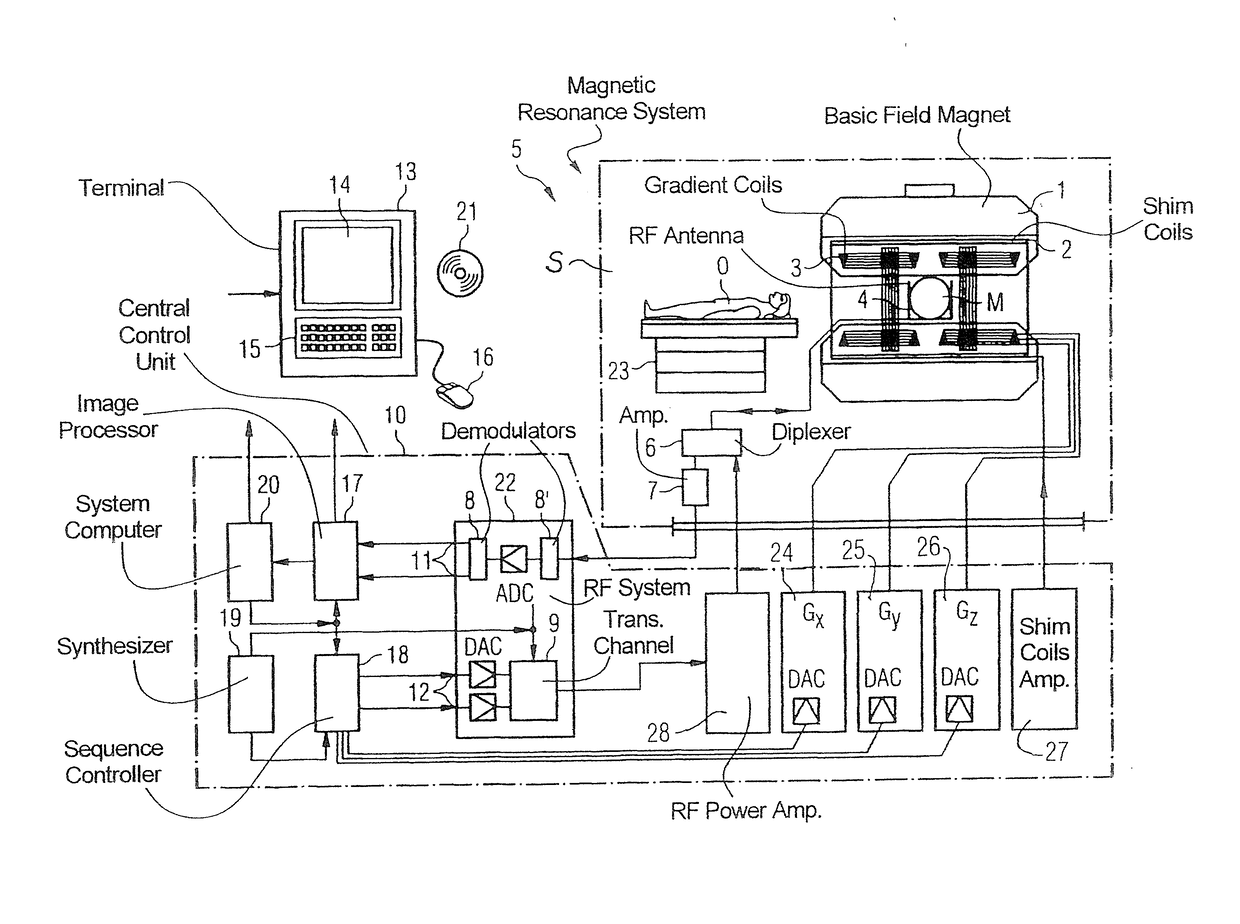

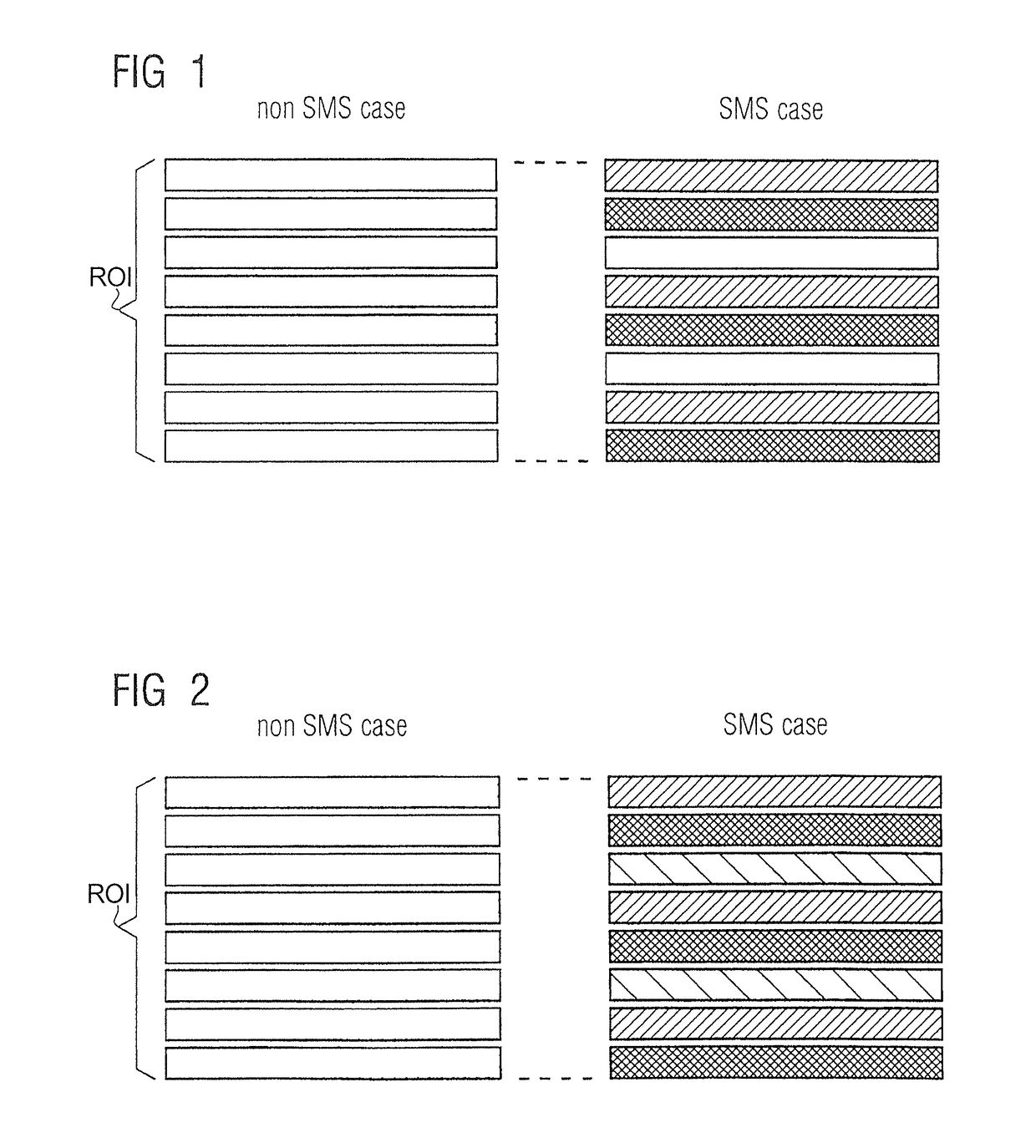

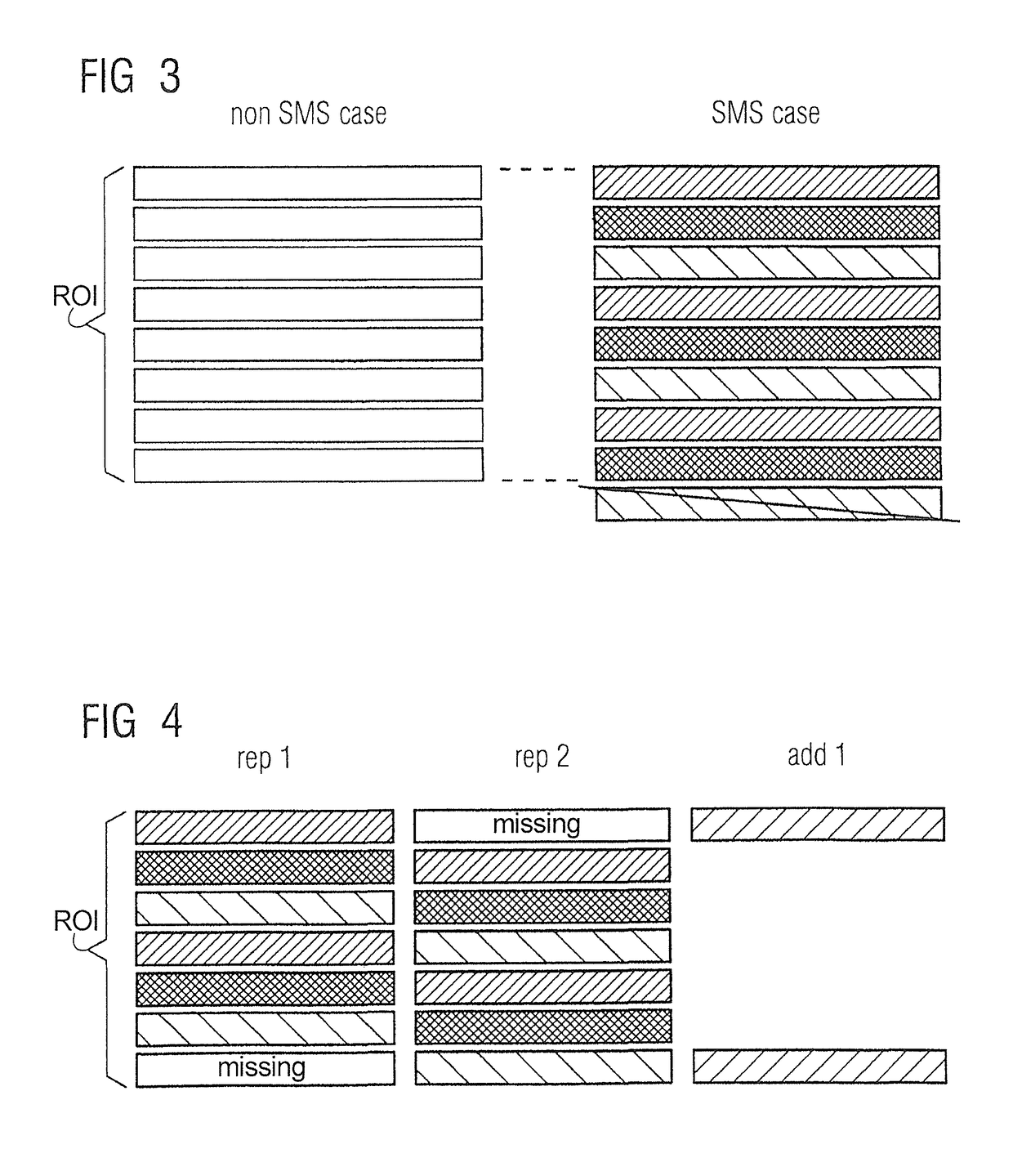

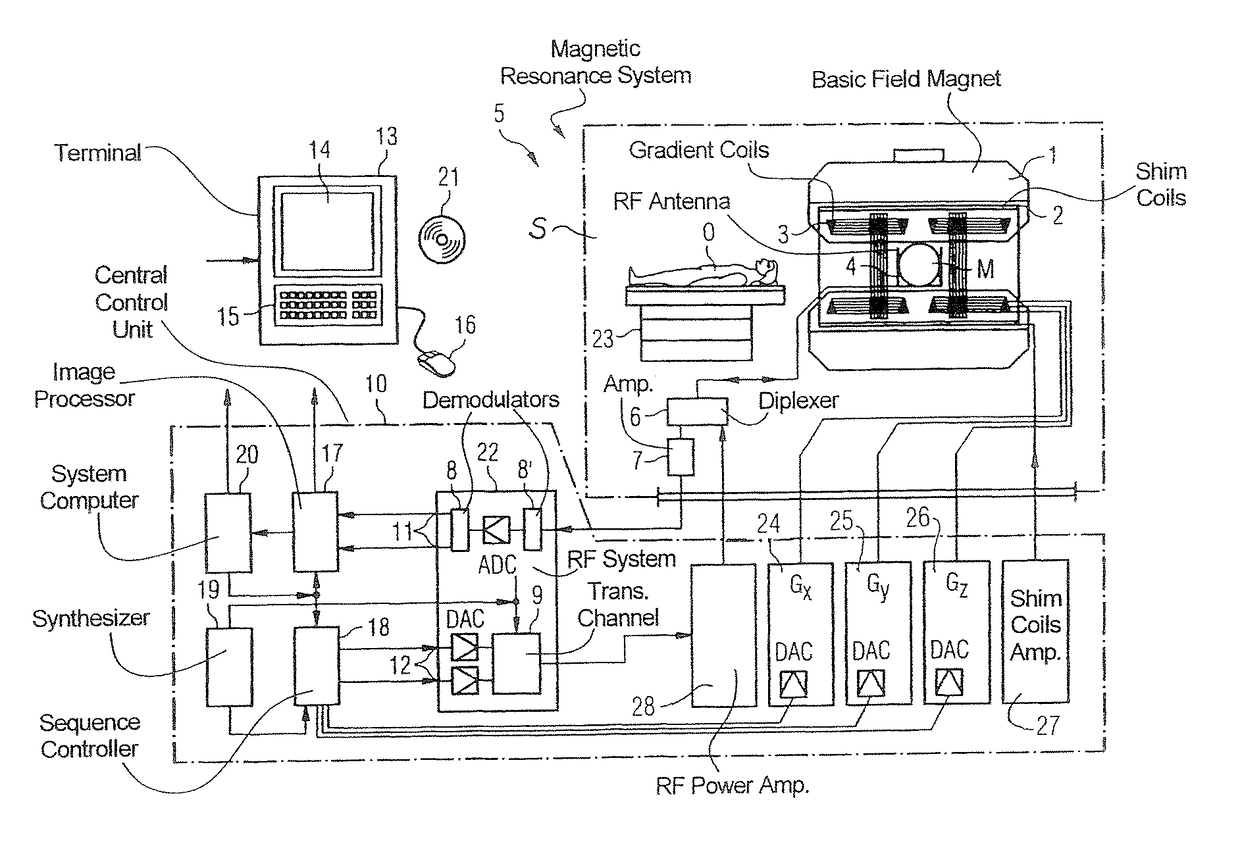

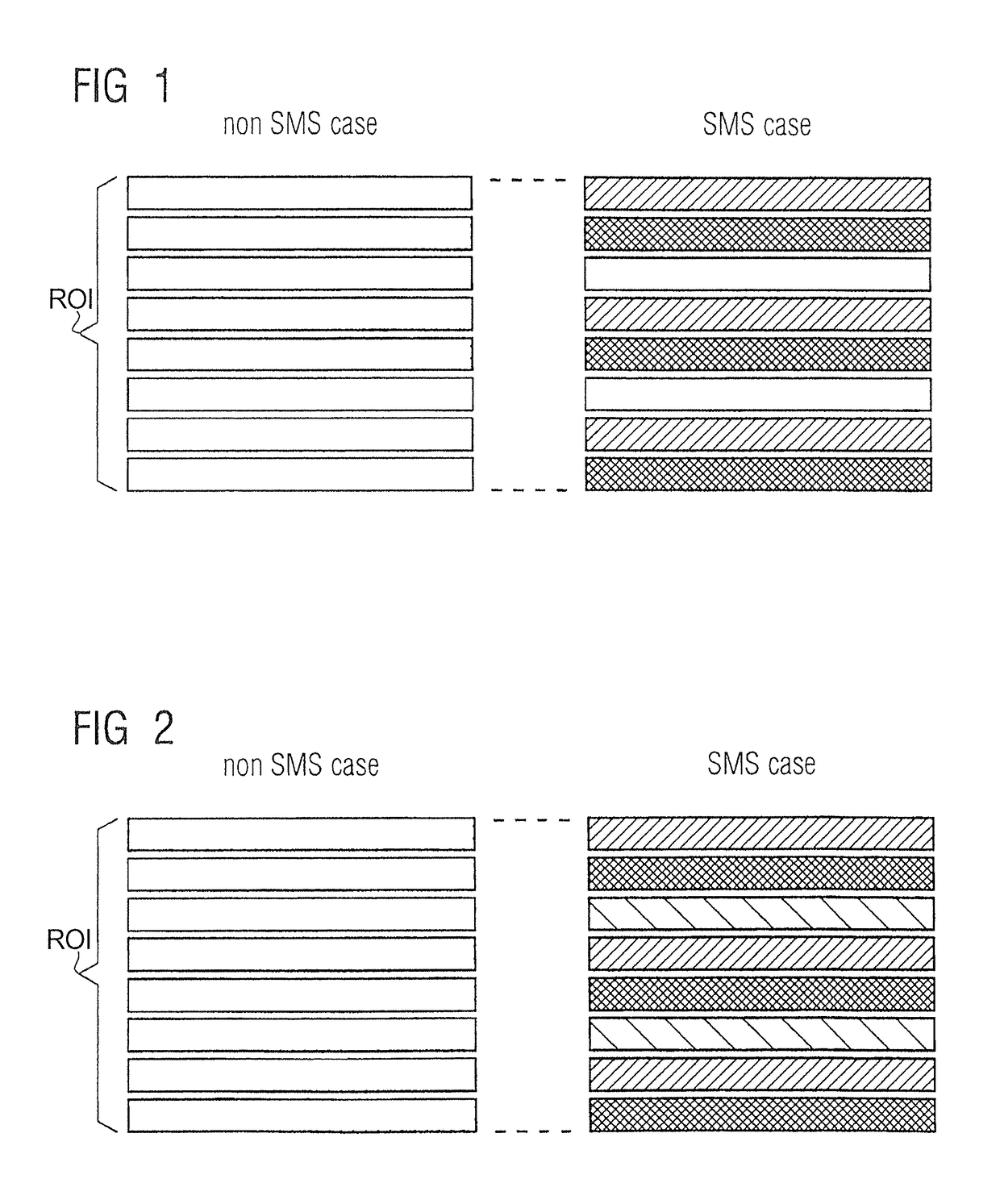

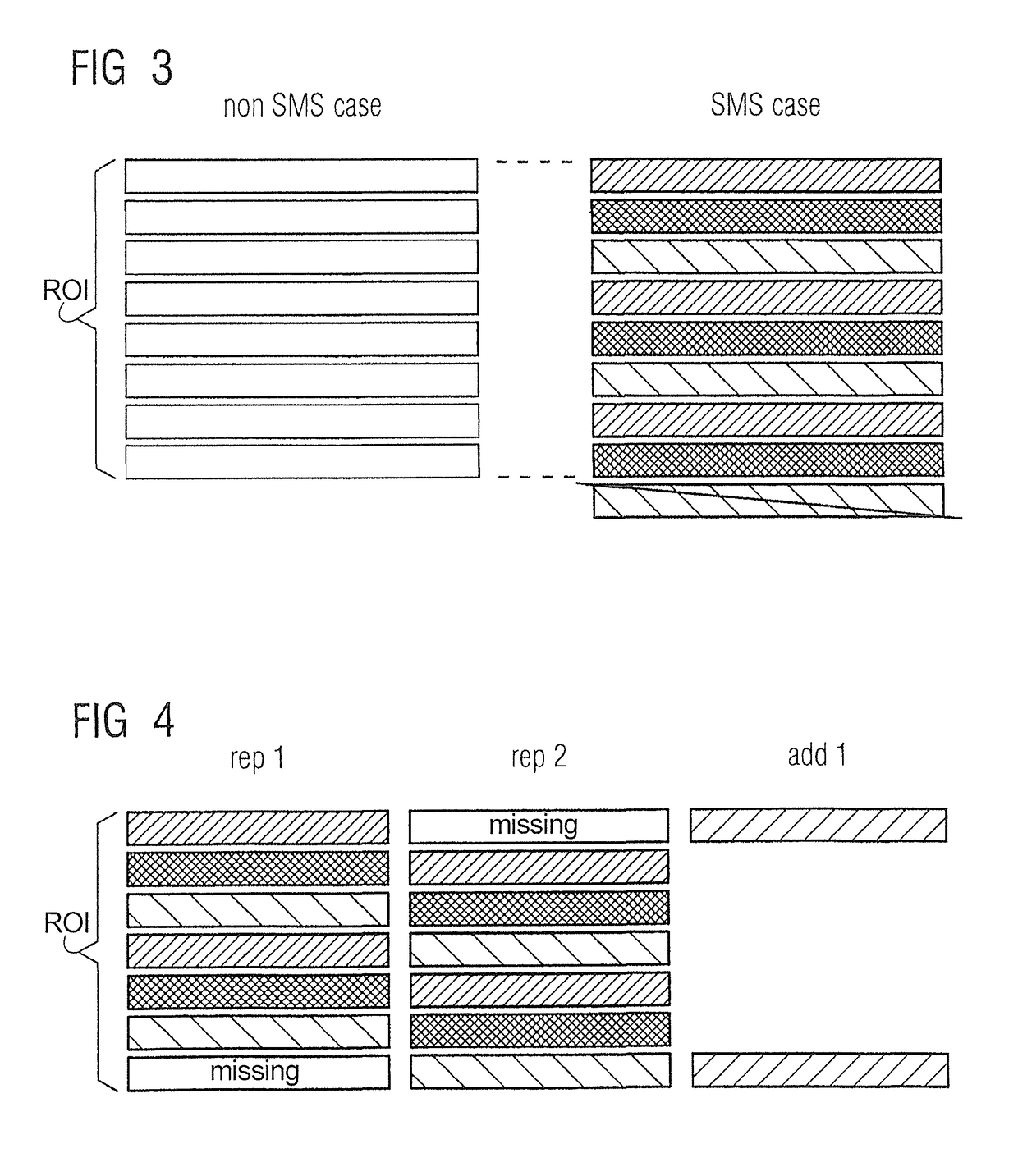

Magnetic resonance apparatus and method for simultaneous multi-slice imaging with arbitrary slice numbers

In a method and apparatus for acquiring magnetic resonance (MR) data from a subject, wherein the MR data are acquired in respective data sets individually from multiple slices in a stack within the examination subject, and wherein the number of slices in the stack is not an integer multiple of a number of slices that are desired to be scanned simultaneously, a quotient of the number of slices in the stack and the number of slices to be acquired simultaneously is formed. A protocol for operating the scanner of the apparatus is then determined wherein the number of simultaneously scanned slices is set either by rounding by quotient up to the next highest integer, or rounding the quotient down to the next lowest integer.

Owner:SIEMENS HEALTHCARE GMBH

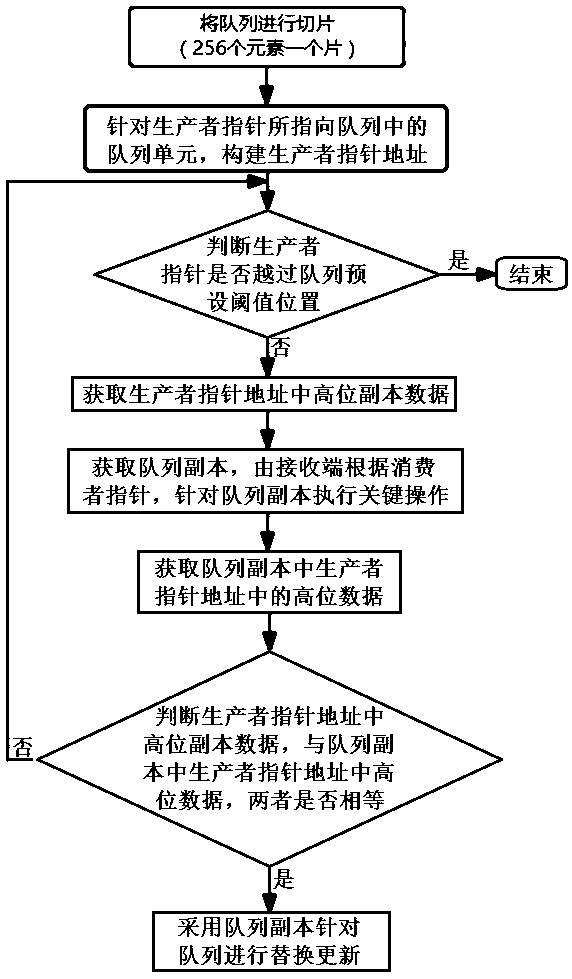

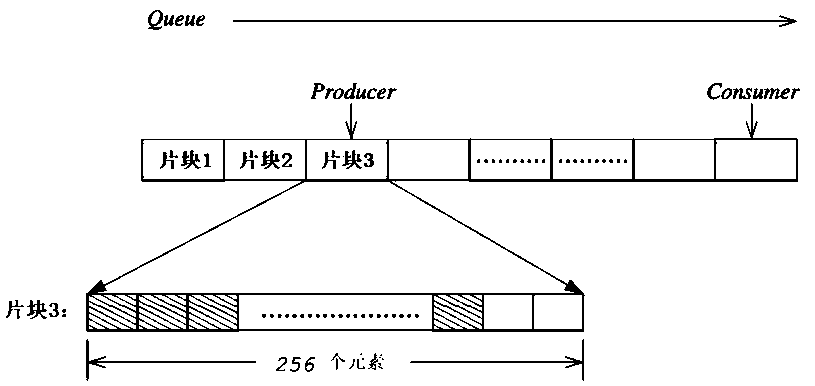

Queue CAS atomic operation control method

ActiveCN108509186AImprove efficiencyReduce failure rateProgramming languages/paradigmsSingle elementTheoretical computer science

The invention relates to a queue CAS atomic operation control method, which, based on a queue slicing thought, is used for solving the problem of failure of indirectly judging CAS under the conditionof range-based atomic operation maximum because a CAS loop statement is used for judging a single pointer position of a producer in the prior art. Through the design method, queue elements are sliced,a single element position pointed by a head of the producer is no longer purely judged, and instead, slice number values pointed by the pointer of the producer before and after CAS judgment are judged, so that the efficiency of a queue algorithm is greatly improved.

Owner:NANJING UNIV OF POSTS & TELECOMM

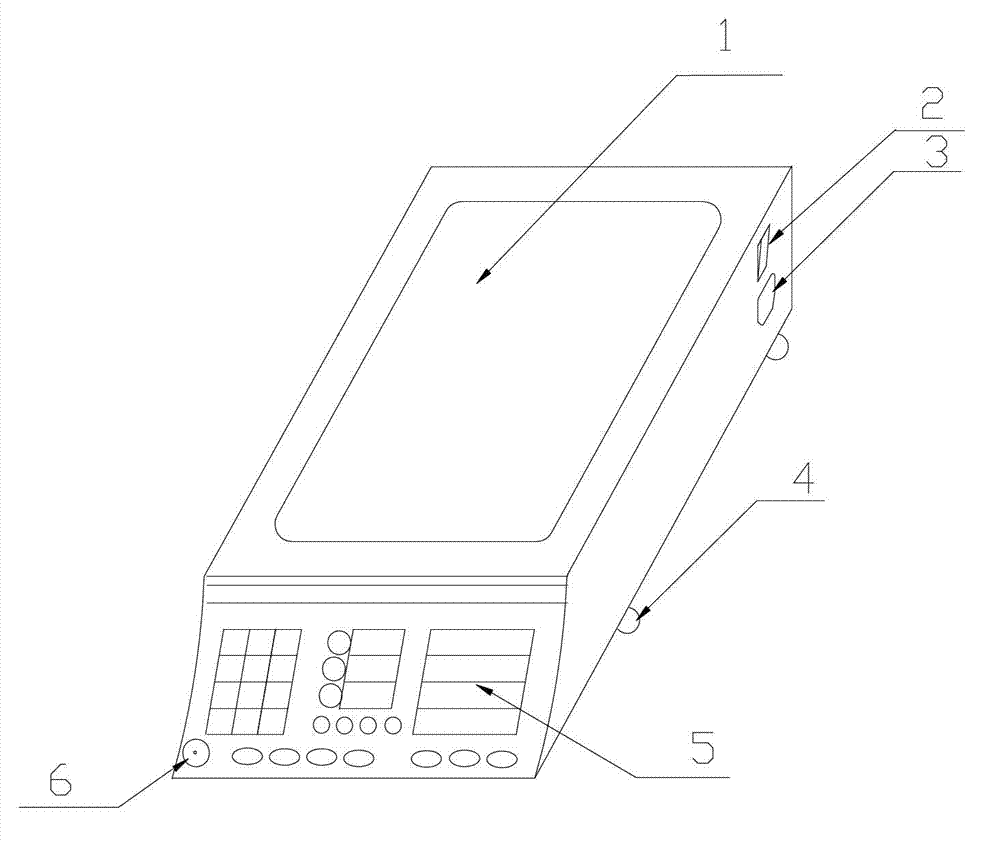

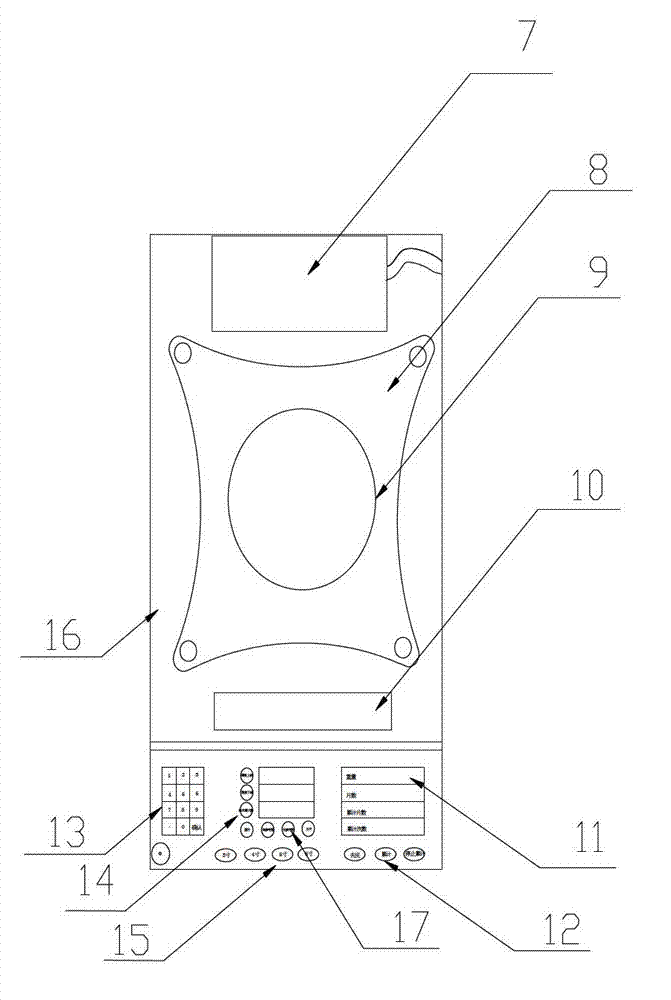

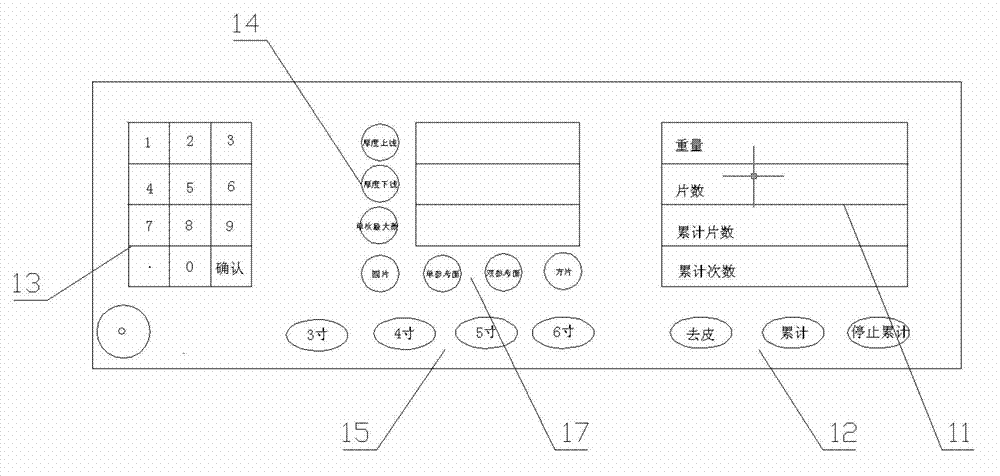

Silicon slice automatic slice counting device based on electronic balance

ActiveCN103033247ARealize spot countingSpecial purpose weighing apparatusSlice thicknessDisplay device

The invention discloses a silicon slice automatic slice counting device based on an electronic balance. The silicon slice automatic counting device based on the electronic balance comprises the electronic balance which comprises an input and display panel. An internal signal processing device is arranged inside the electronic balance. A numerical value input device, a silicon slice thickness choosing and display device, a silicon specification choosing device a silicon slice size choosing device and a counting result display device are arranged on the input and display panel. After information is input by the input and display panel and processed by the internal signal processing device, silicon slice counting result is displayed. The silicon slice automatic counting device based on the electronic balance is developed based on a common electronic balance, slice number is counted by the utilization of an intrinsic physical property between weight and density, slicing counting of silicon slices can be achieved with high efficiency, and the silicon slice automatic counting device based on the electronic balance has the advantages of being convenient to use, practical and cheap.

Owner:ZHEJIANG COWIN ELECTRONICS

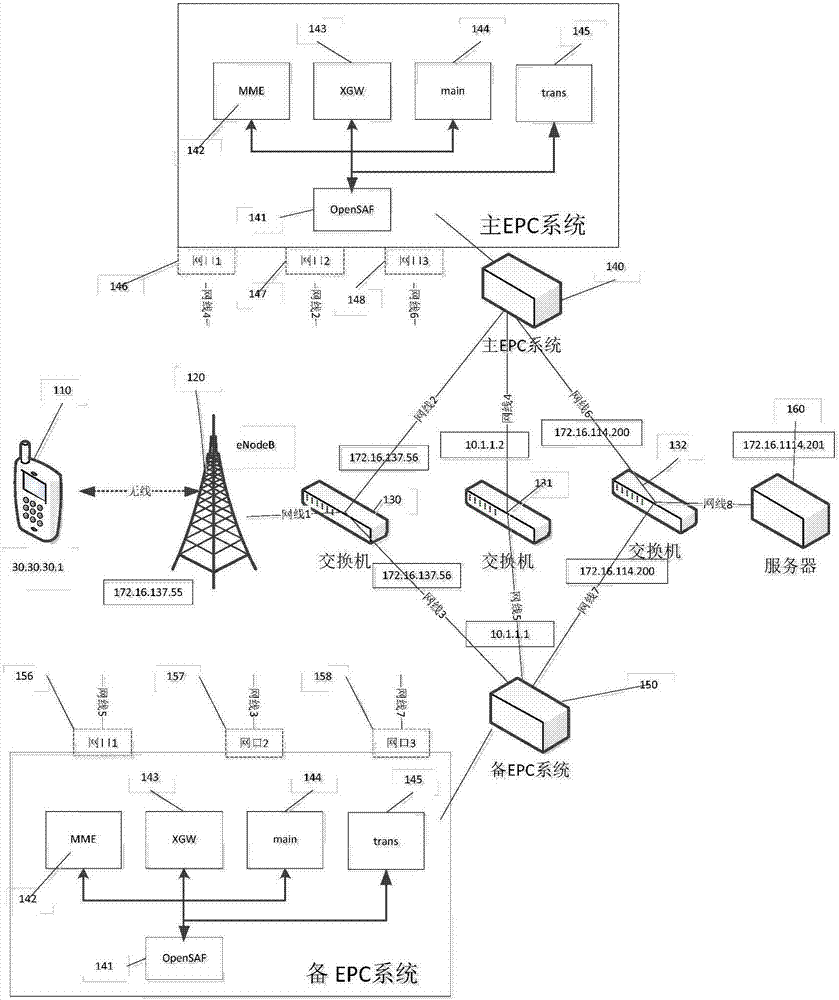

Data backup method for LTE EPC (Long Term Evolution Evolved Packet Core) system

ActiveCN107318121AIncrease flexibilityReduce the number of backupsData switching networksWireless communicationComputer moduleData needs

The invention provides a data backup method for an LTE EPC (Long Term Evolution Evolved Packet Core) system. Two EPC systems: a master EPC system and a standby EPC system are set. The two EPC systems comprise EPC modules, OpenSAF modules and network devices. In a process of starting all processes of an EPC by a main EPC system, when terminals have service operation, each process stores data needing to be backed up to a corresponding slice number and sends backup data to the OpenSAF. After the standby EPC system starts the EPC, the backup data of the master EPC system is received, and each process receives messages and extracts and restores the data according to the slice numbers. If the standby EPC system does not start the EPC process, the OpenSAF stores the backup data of each process; each block of data corresponds to the unique slice number; and when backup is carried out on a certain slice number for N times, restoration is carried out for one time. The backup times is reduced; hot backup and cold backup are supported; real-time backup is realized; a partial backup and integrated backup function is realized for a data structure; and the backup and storage efficiency is improved.

Owner:WUHAN HONGXIN TECH DEV CO LTD

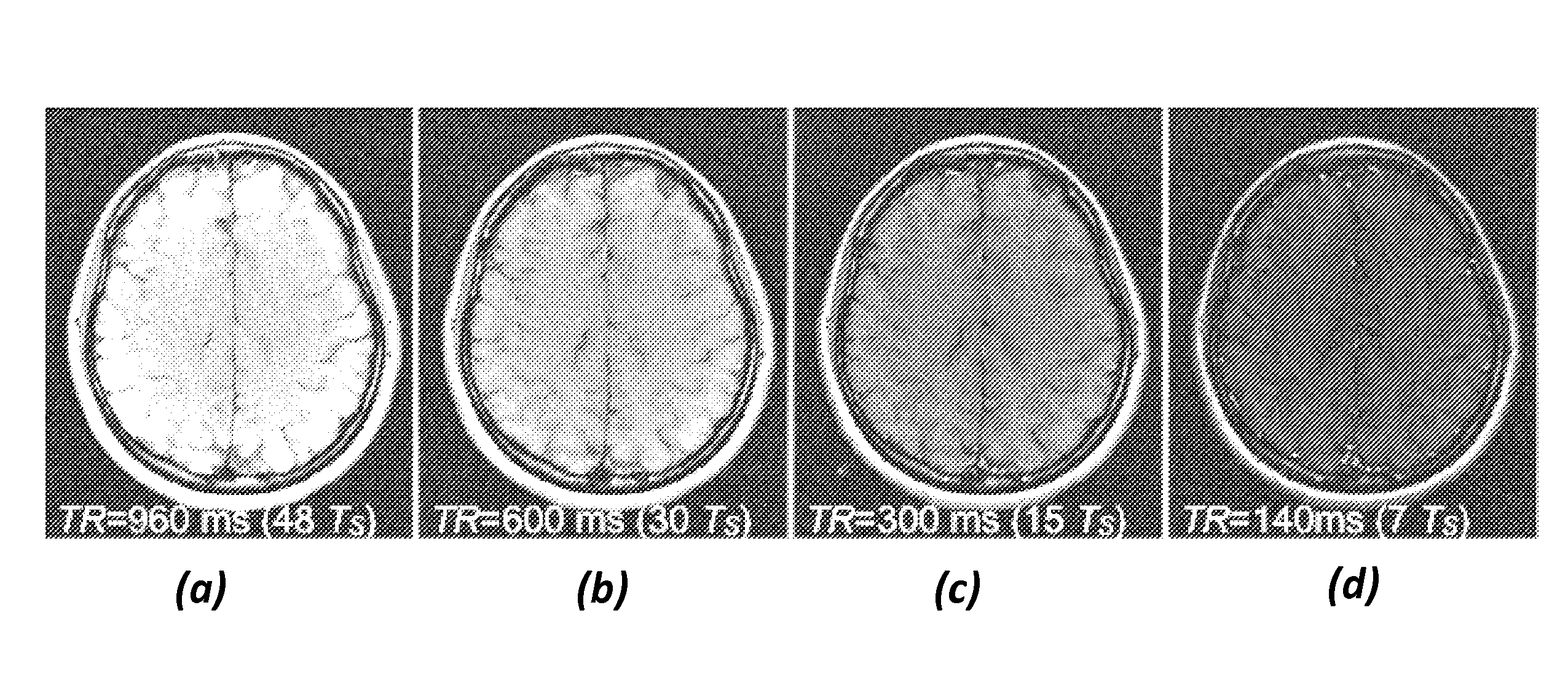

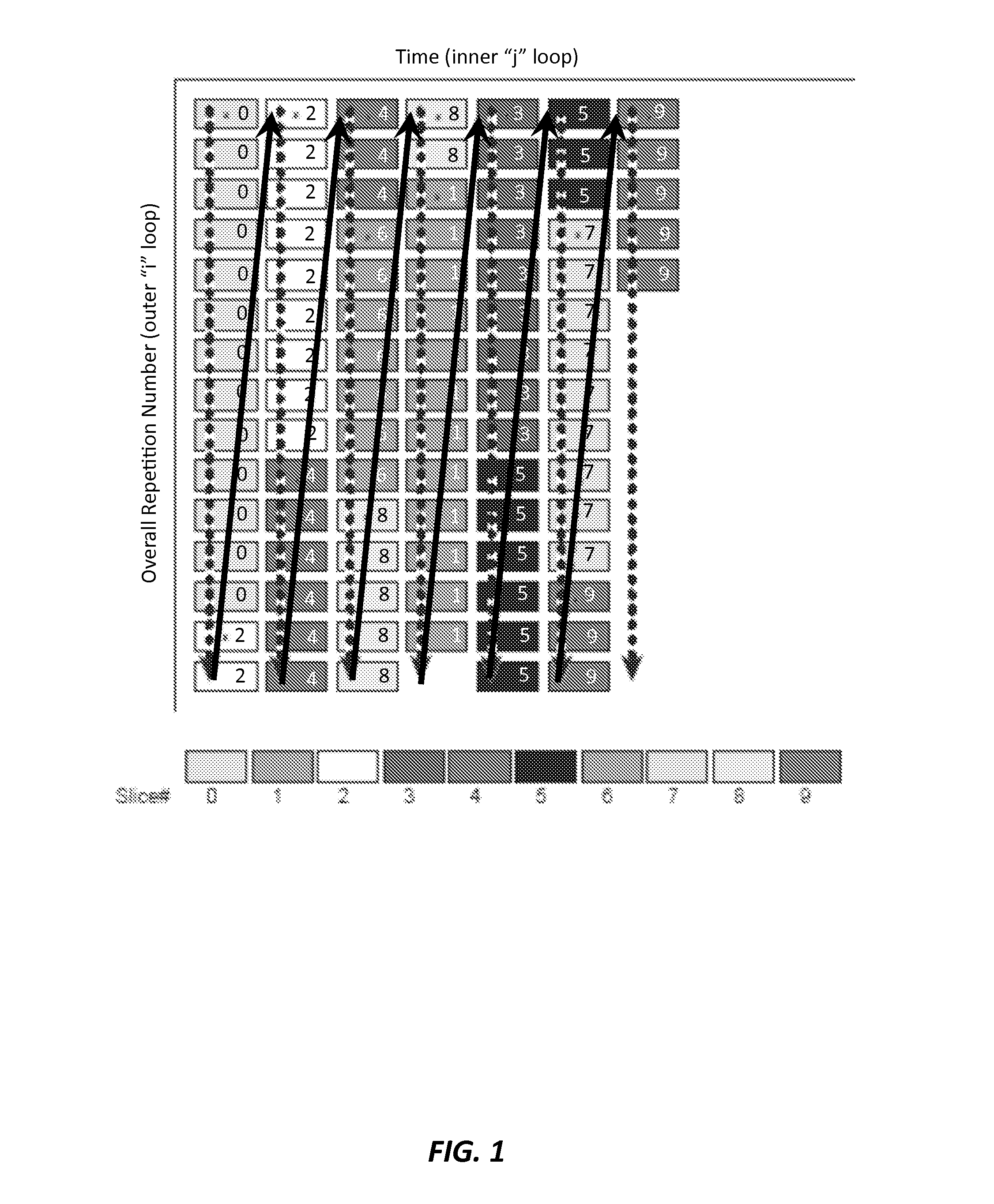

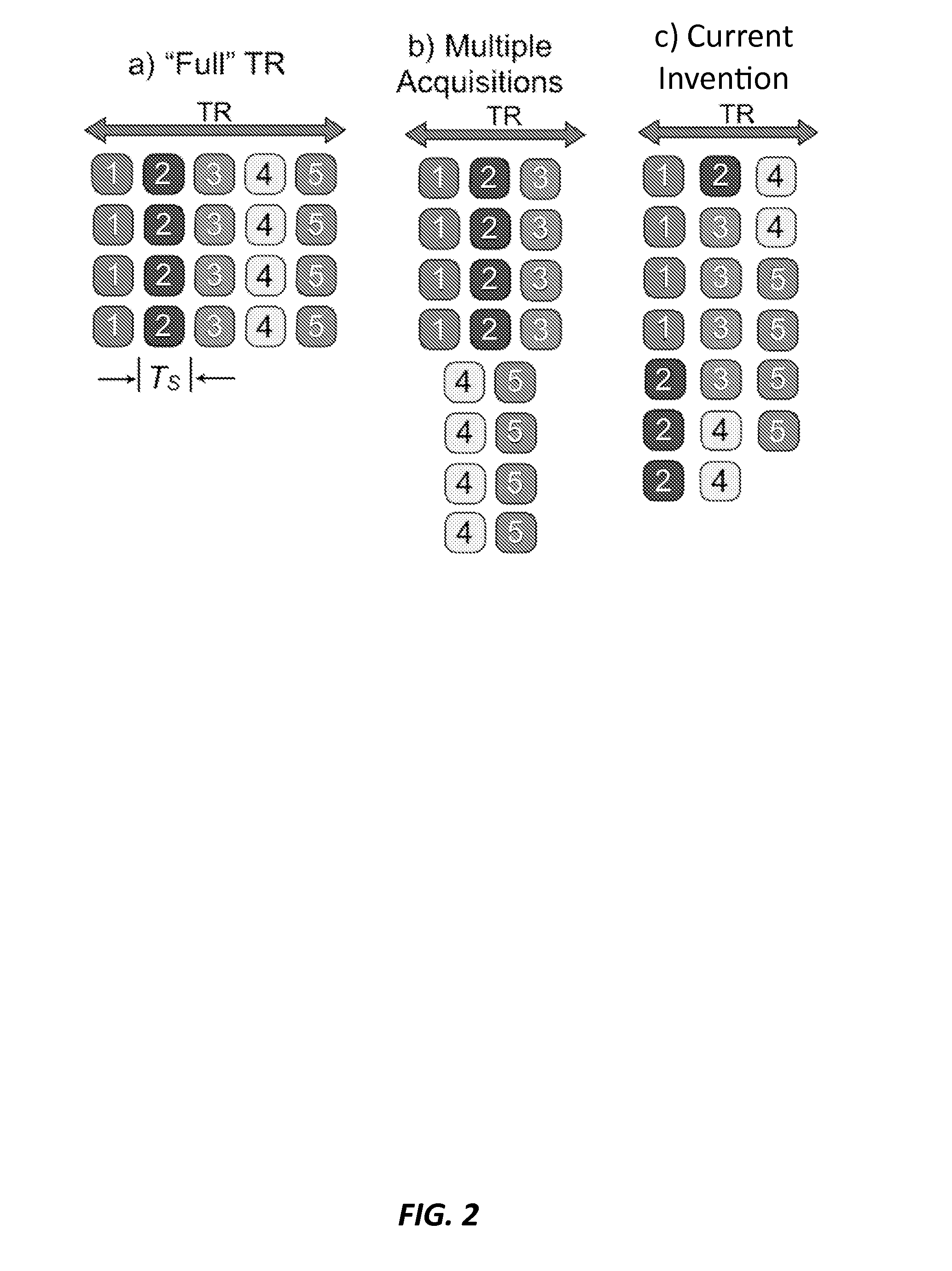

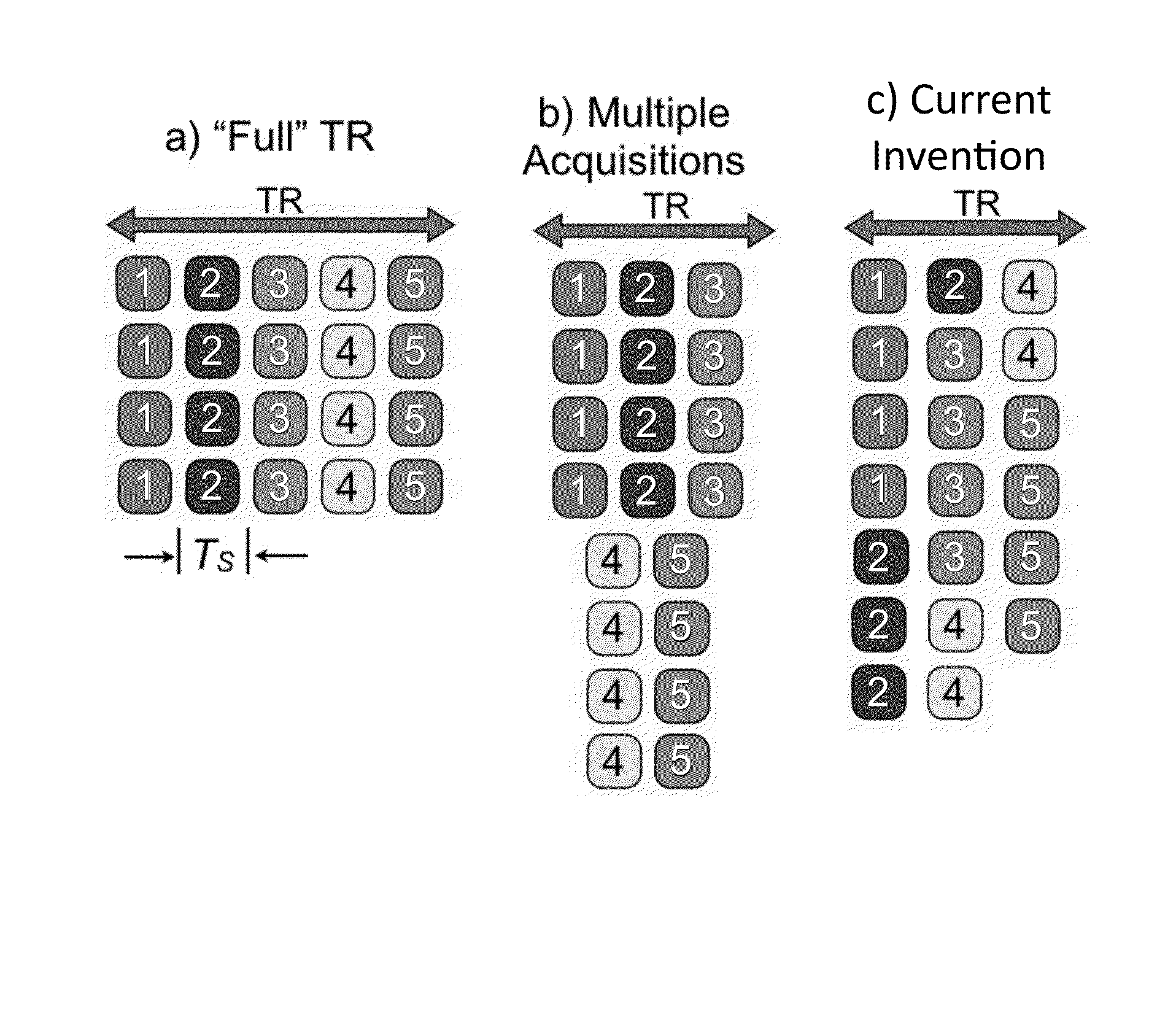

Flexible Ordering for Multiple Slice MRI

ActiveUS20130200892A1Measurements using NMR imaging systemsElectric/magnetic detectionComputer scienceSlice Number

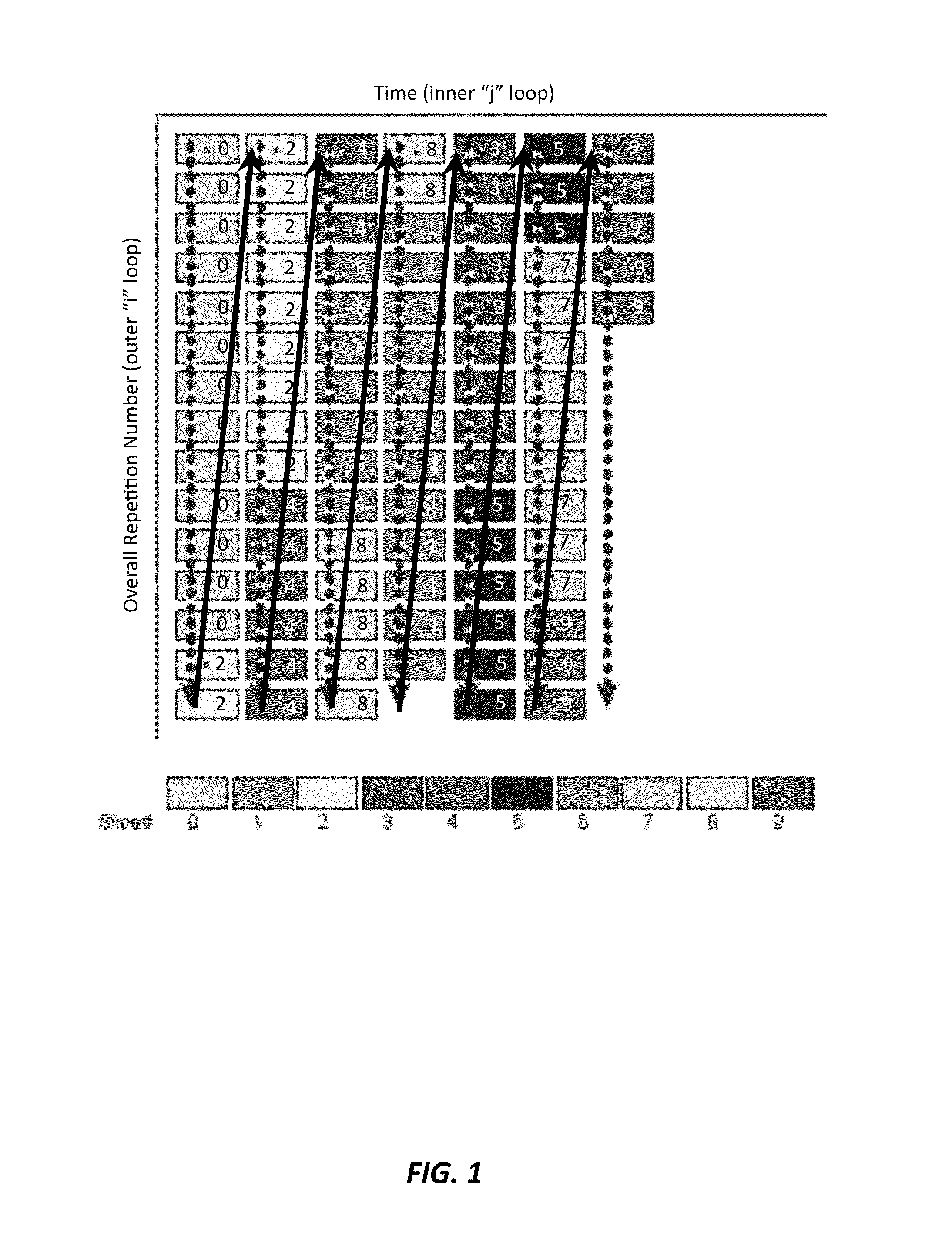

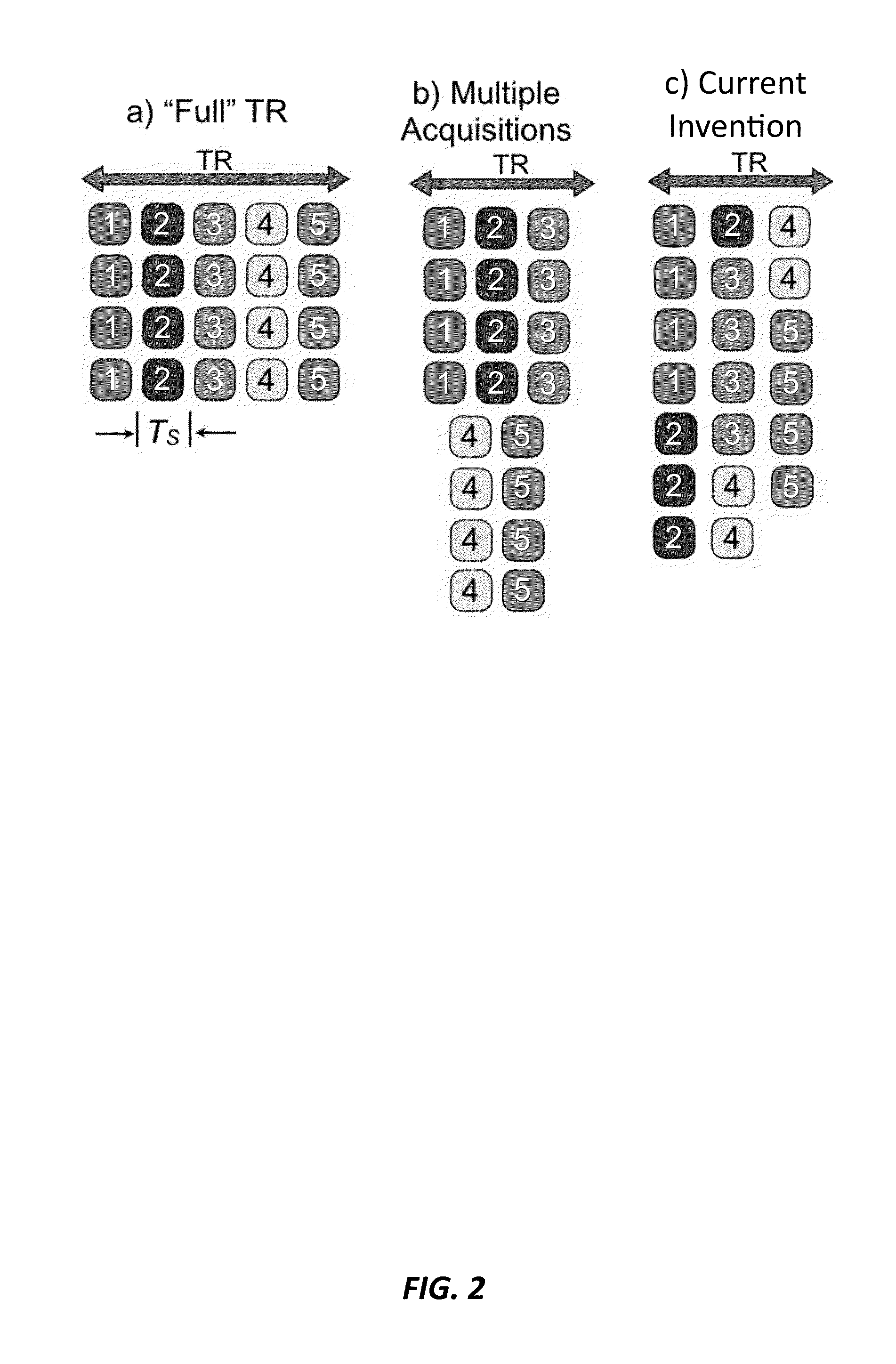

A method of ordering slices for interleaved MRI is provided that includes selecting a number of interleaved slice locations (NS) each having a plurality of excitations (NE,S), where S is the slice number between 1 and NS and NE,S may differ for different slice numbers, selecting an excitation duration (TS) of each the excitation in each the slice, selecting a repetition time (TR) between successive excitations of the same slice, TR has a duration of Ni×TS, Ni is the number of interleaved slices per TR period, and arranging the order for the slices such that the total scan time (T) is minimized such that TR is the product of Ni and Ts, where Ni can be arbitrarily chosen between 1 and NT / NE,max where NT is the total number of excitations for all the slices and where NE,max is the maximum number of the excitations for one slice.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

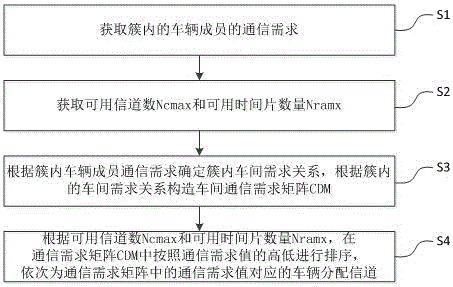

Inter-vehicle-communication-demand-based intra-cluster channel distribution method

ActiveCN105828440AReliable transmissionAvoid congestionWireless communicationDistribution methodInter vehicle communication

The invention discloses an inter-vehicle-communication-demand-based intra cluster channel distribution method. The method comprises: vehicle states of vehicle members in a cluster are obtained, wherein the vehicle states include healthy states and position information of the vehicle; an available channel number Ncmax and an available time slice number Nramx are obtained; according to the vehicle states of the vehicle members in the cluster, intra-cluster inter-vehicle communication demand relationships are obtained, and an inter-vehicle communication demand matrix (CDM) is constructed based on the intra-cluster inter-vehicle communication demand relationships; and according to the available channel number Ncmax and the available time slice number Nramx, priority sorting is carried out in the CDM according to communication demand values sizes, and then channel distribution is carried out on vehicles corresponding to the communication demand values. With the method, safety warning information is transmitted by using a multi-frequency-point division time slice, so that the channel competition and channel congestion can be avoided effectively and thus the safety warning information can be transmitted to a target vehicle reliably in real time.

Owner:CHONGQING UNIV

Coding method for all-depth-of-field imaging of range-gating-based laser radar

ActiveCN109521439AImprove detection efficiencyRealize full depth imagingElectromagnetic wave reradiationArray data structurePulse number

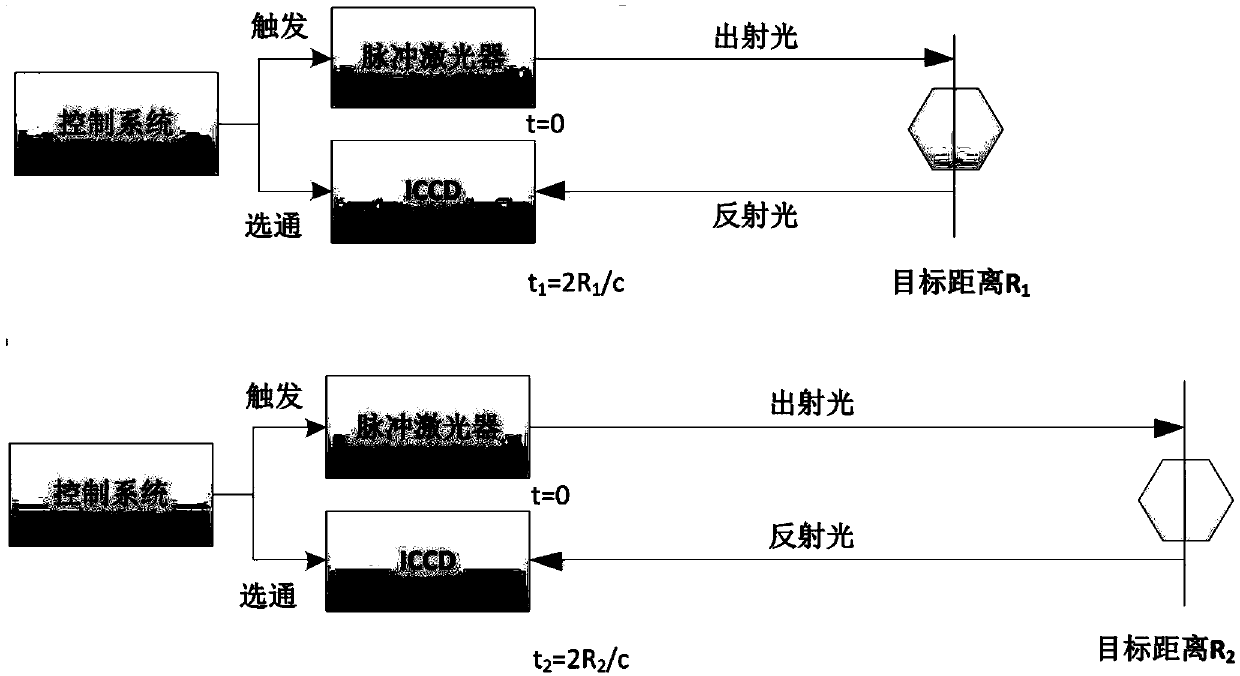

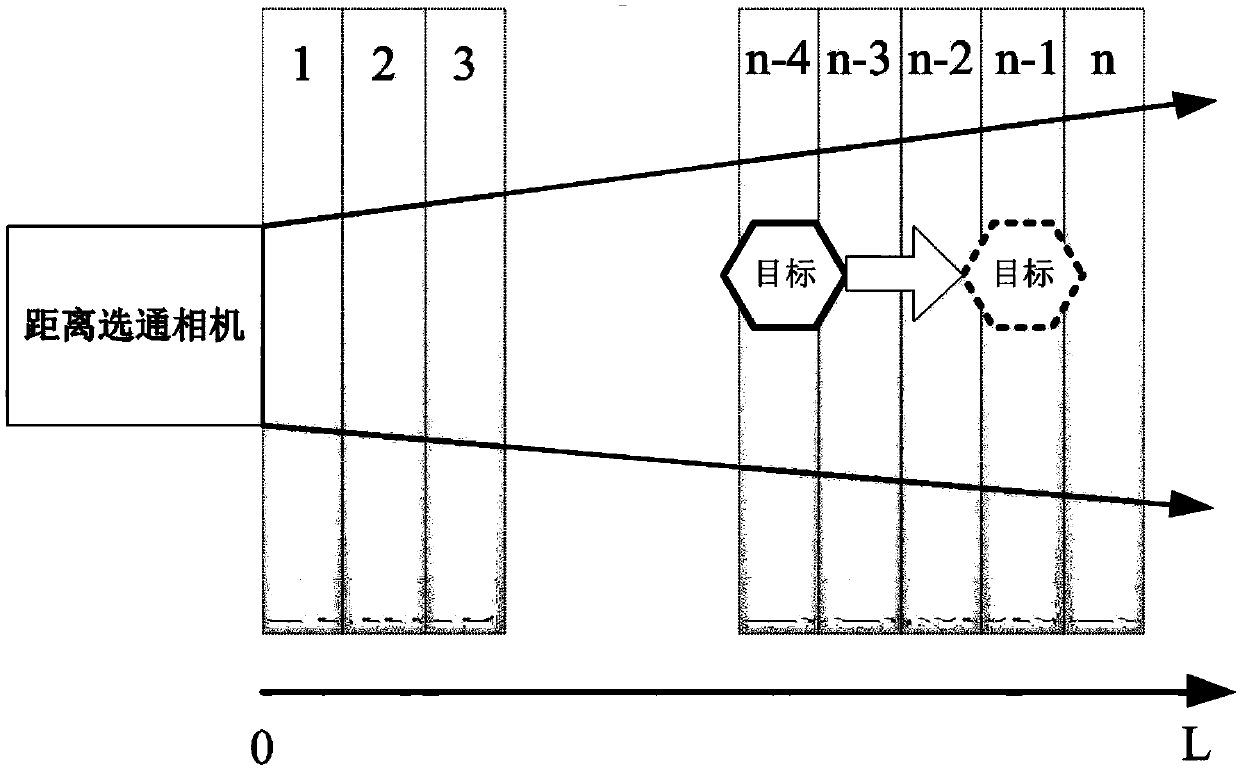

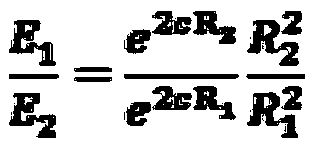

The invention relates to a coding method for all-depth-of-field imaging of a range-gating-based laser radar. According to a light attenuation coefficient in a working medium of the laser radar, a total detection distance is determined; a single slice depth of field based on a gated imaging parameter; the needed slice number is determined based on the total detection distance and the single slice depth of field; actual detection distances corresponding to all slices and actually corresponding ICCD opening times of all slices are determined; on the basis of the principle of equal energy of light, a ratio of laser pulse numbers needing to be allocated to all slices is determined; a one-dimensional array is obtained and a sum of the one-dimensional array is calculated; the total laser pulse number of single-frame imaging is determined based on the gated imaging parameter and pulse numbers allocated to all slices actually are determined; and the pulse numbers allocated to all slices actually are determined. With the coding method, the all-depth-of-field imaging in the detection range is realized; and the detection efficiency is improved.

Owner:SHANDONG INST OF AEROSPACE ELECTRONICS TECH

Method for managing stone stock with inventory management system

InactiveCN104867000ATo meet the needs of operating domestic board enterprisesRealize Computational StorageLogisticsEngineeringInventory management system

The invention discloses a method for managing stone stock with an inventory management system, which is used for solving the problem that an inventory form is signal and could not meet the inventory requirement of current stone industry. The method of the invention is used for carrying out double inventory management to the stone by using two inventory modes through arranging a square inventory module and a slice number inventory module. The method specifically comprises in-stockroom operation of the stone, discharging operation of the stone, inventory conversion operation of the stone, inventory verification operation of the stone and inventory allocating operation of the stone. Through the above operation, the method of the invention not only can be used for achieving positive inventory, zero inventory and negative inventory, but also can realize the condition that the stone enterprise inventory can be stored in a combined manner of calculating according to square and according to slice number to meet the requirement of domestic and import stone concurrent enterprise.

Owner:CHENGDU HAISAN TECH

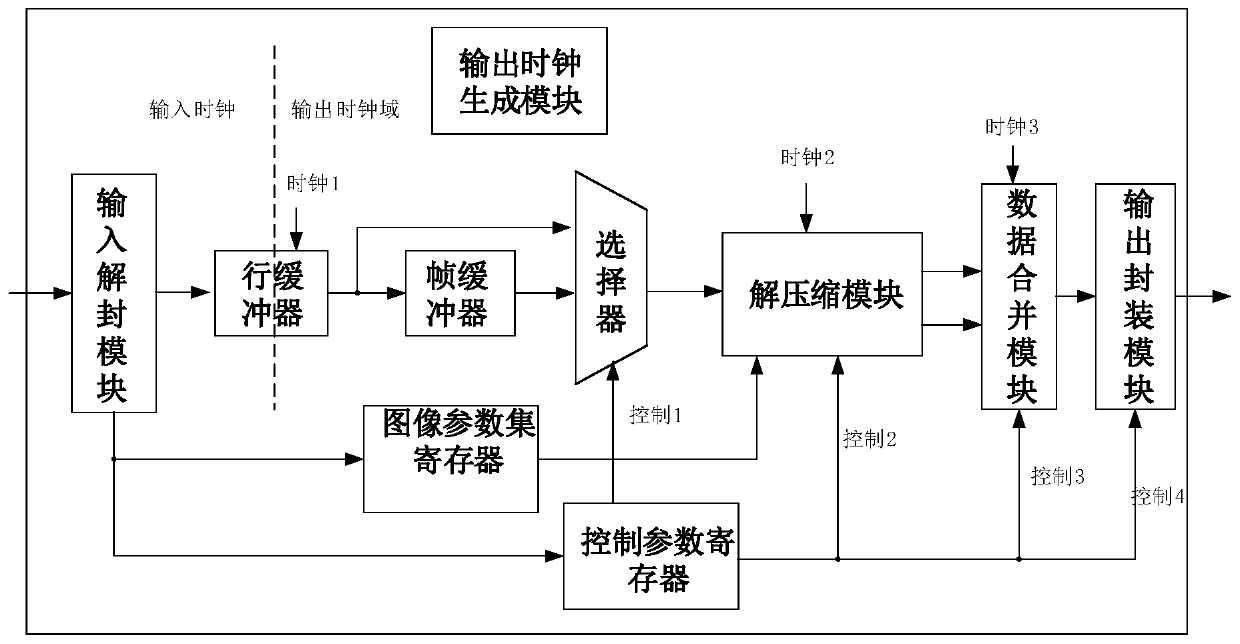

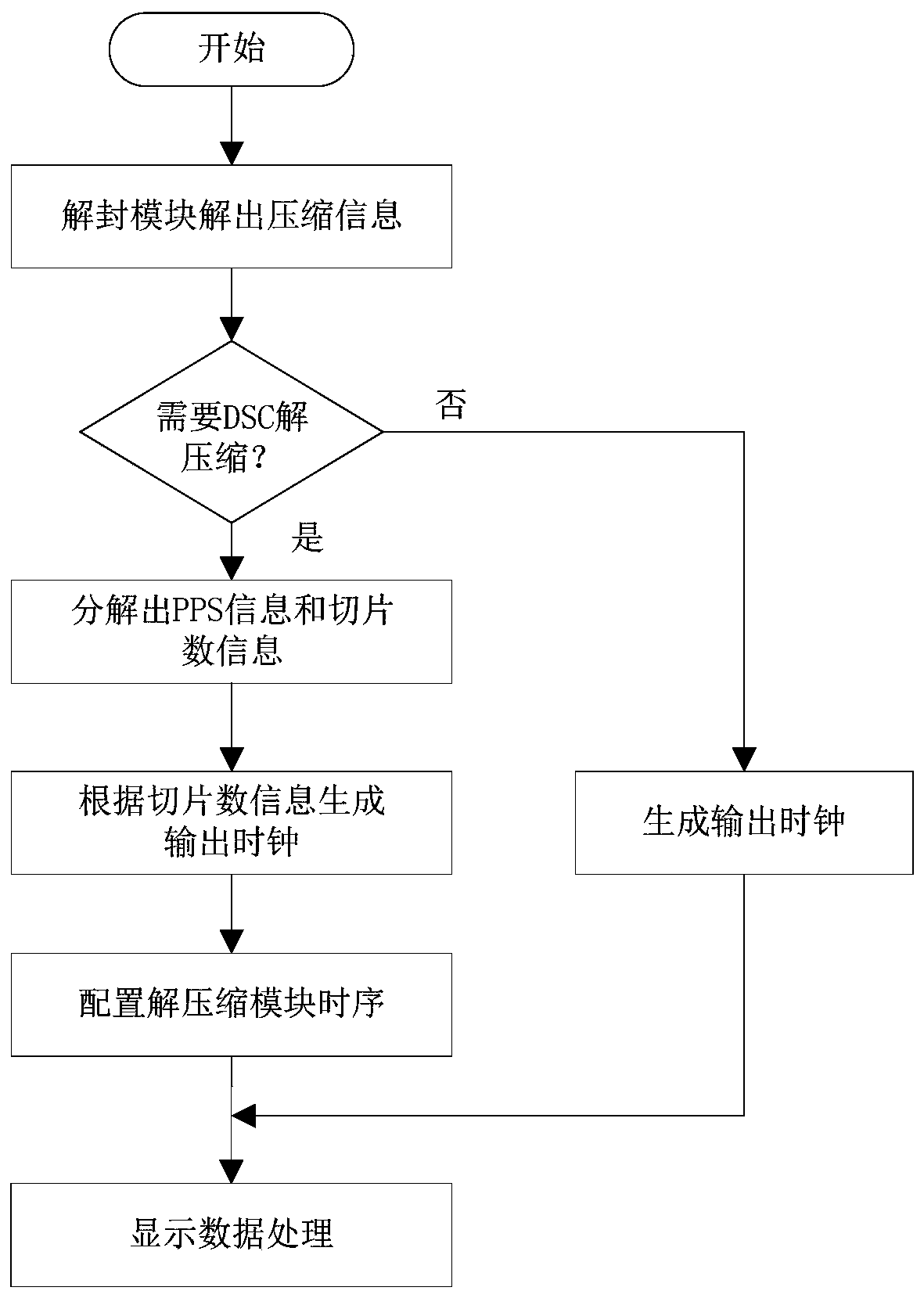

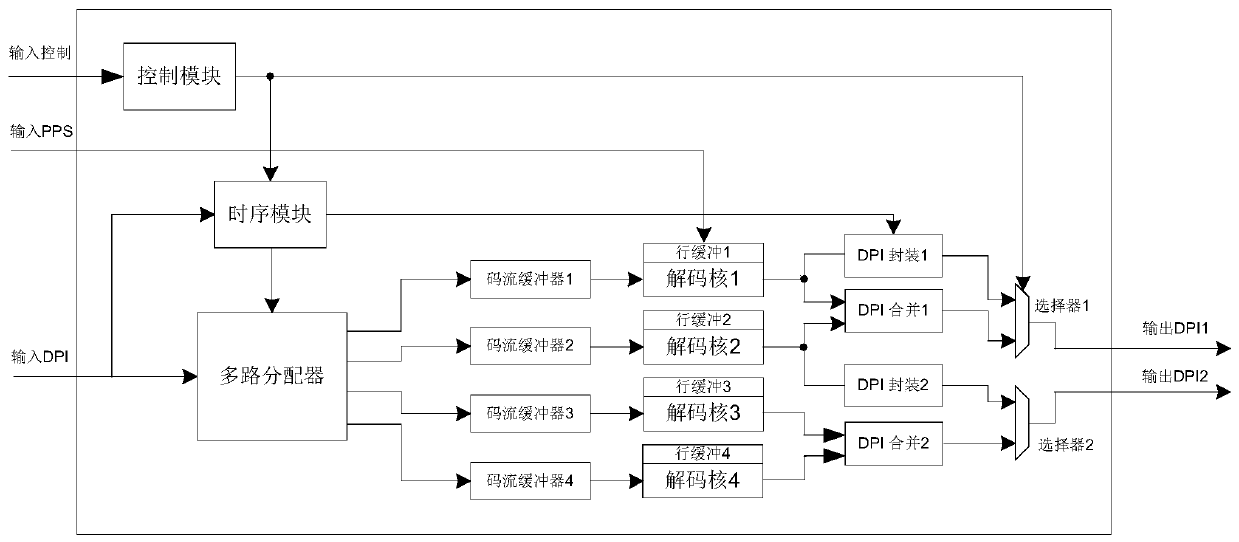

A computer readable storage medium and a display stream compression decoding module and display interface interaction device applying the same

ActiveCN109831671AWith compression ratioEasy to operateTelevision system detailsColor television detailsClock rateComputer module

The invention relates to the technical field of display processing, in particular to a computer readable storage medium and a display stream compression decoding module and display interface interaction device applying the same, a computer program is stored in the medium, and the computer program can be executed by a processor of the display stream compression decoding module and the display interface interaction device. The DSC standard V1.1 specifies that bit stream compression has a fixed compression ratio while the number of slices of a complete image may be 1, 2 or 4. Slice number information is obtained through calculation of a coded and transmitted image parameter set, clock frequencies needed by all the modules are automatically distributed, the input and output time sequence of decoding is controlled, and the method has the advantage of being easy to operate. Data for displaying a serial interface is converted into a DSC bit stream on hardware, and a decoding algorithm in a VESA association DSC standard V1.1 is realized by using the hardware, so that the method is simple and cheap to implement on conventional hardware.

Owner:SHENZHEN AIXIESHENG TECH CO LTD

Flexible ordering for multiple slice MRI

A method of ordering slices for interleaved MRI is provided that includes selecting a number of interleaved slice locations (NS) each having a plurality of excitations (NE,S), where S is the slice number between 1 and NS and NE,S may differ for different slice numbers, selecting an excitation duration (TS) of each the excitation in each the slice, selecting a repetition time (TR) between successive excitations of the same slice, TR has a duration of Ni×TS, Ni is the number of interleaved slices per TR period, and arranging the order for the slices such that the total scan time (T) is minimized such that TR is the product of Ni and Ts, where Ni can be arbitrarily chosen between 1 and NT / NE,max where NT is the total number of excitations for all the slices and where NE,max is the maximum number of the excitations for one slice.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

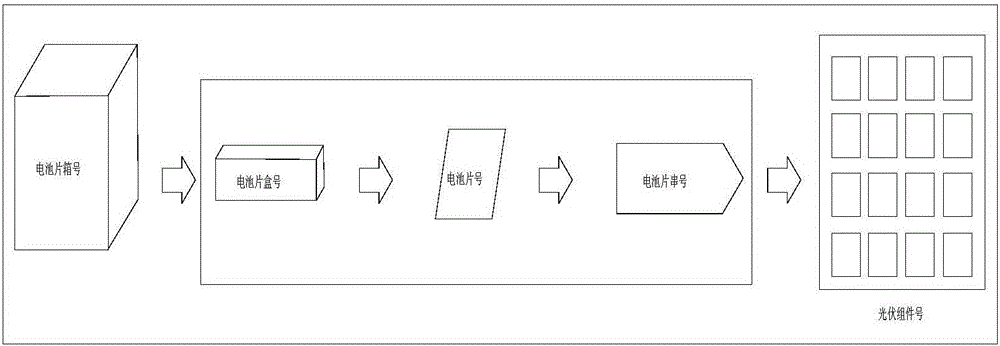

Cell slice tracking information generating method and system, and tracking method and system

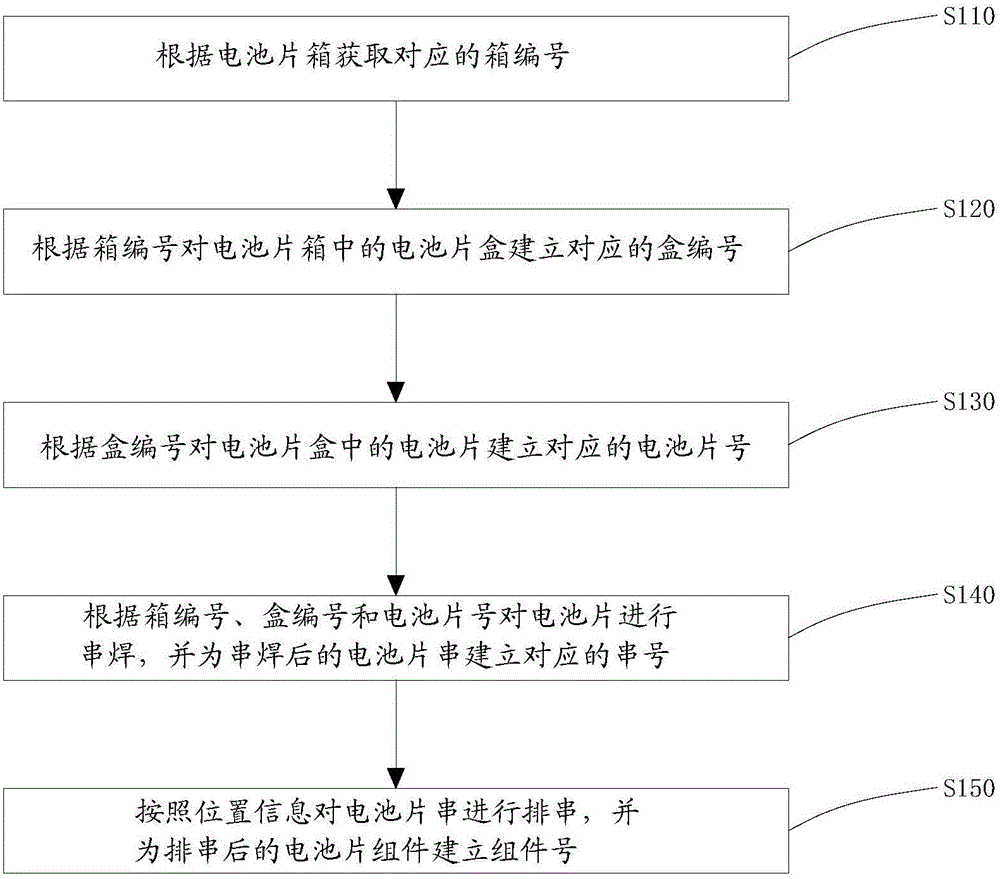

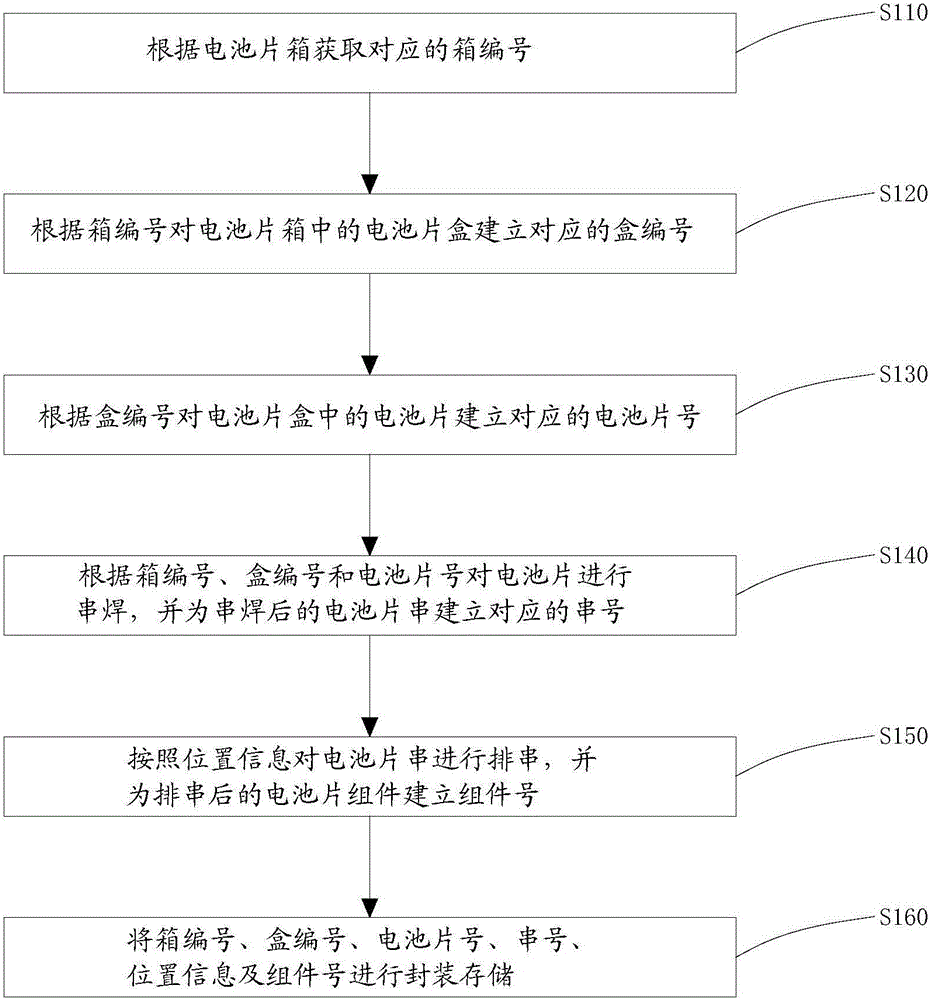

The invention relates to a cell slice tracking information generating method and system, and a tracking method and system. The generation method comprises: obtaining a corresponding case number according to a cell slice case; establishing corresponding box numbers for the cell slice boxes in the cell slice case according to the case number; establishing corresponding cell slice numbers for the cell slices in the cell slice boxes according to the box numbers; series welding the cell slices according to the case number, boxes numbers and cell slice numbers, and establishing corresponding serial numbers for the cell slices after series welding; and arranging cell slice strings according to position information, and establishing module numbers for the cell slice modules after string arrangement. The tracking method can track cell slices according to the generation method, track cell slice production line, production processes, production time, etc., and effectively avoid photovoltaic module faults.

Owner:ZHANGJIAGANG GCL INTEGRATION TECH CO LTD +3

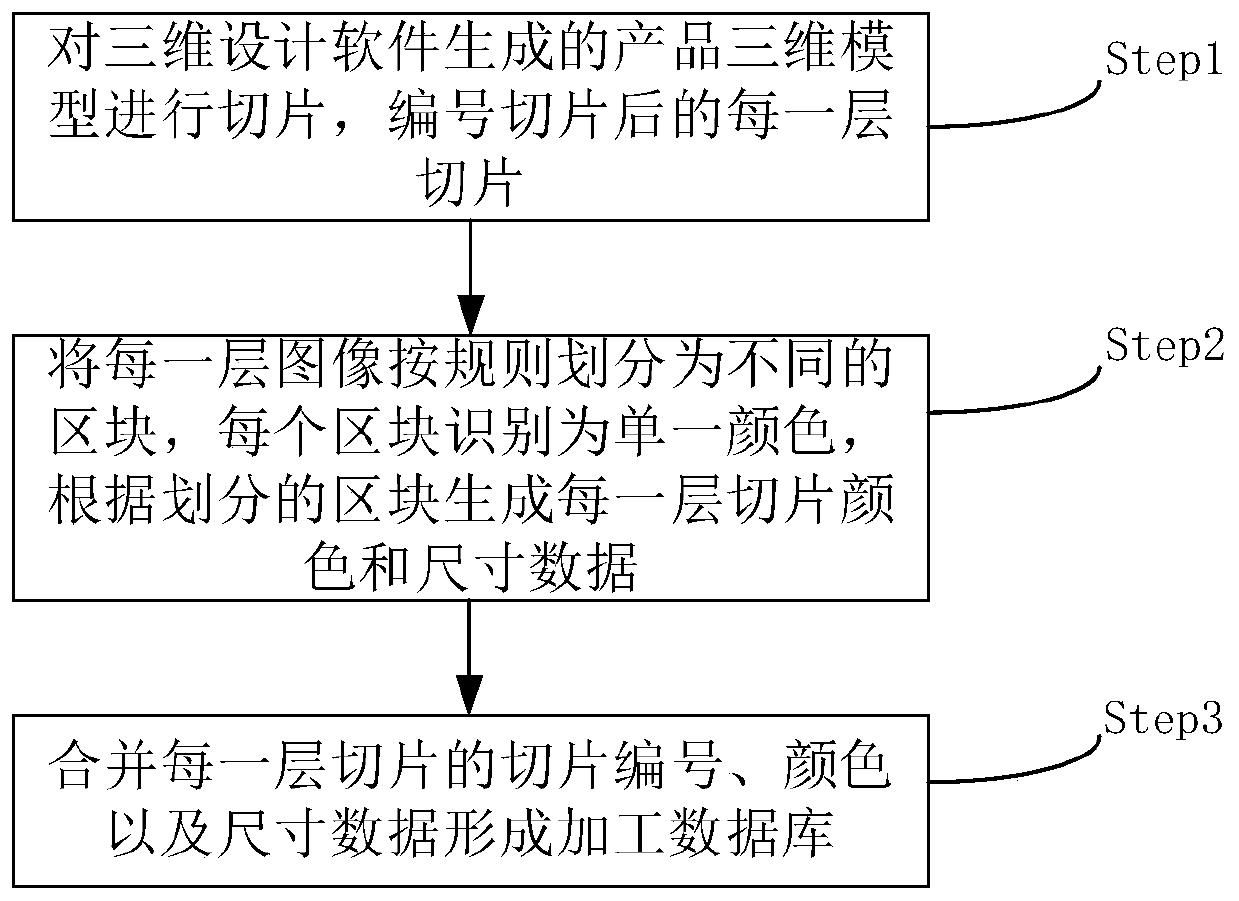

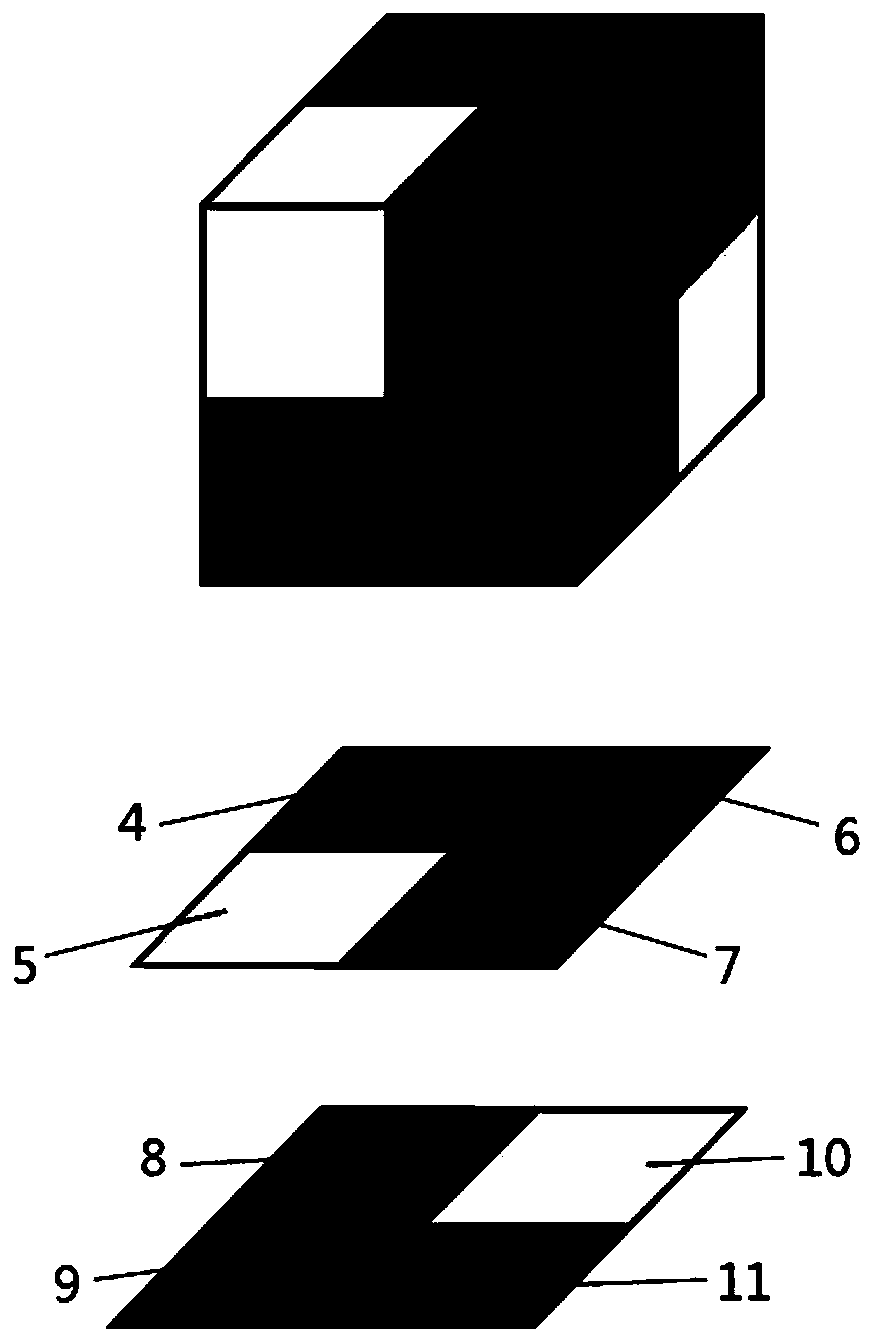

Software slicing method based on colored photocuring 3D printer

InactiveCN110053263AImplement codingRealize multi-color printingAdditive manufacturing apparatusManufacturing data aquisition/processing3d printerComputer science

The invention discloses a software slicing method based on a colored photocuring 3D printer. The method comprises the following steps: slicing a product three-dimensional model generated by software,and numbering each layer of slice after slicing; dividing each layer of image into different zones according to a rule, identifying each zone as a single color, and generating color and size data of each layer of slice according to the divided zones; and then combining slice numbers, color data and size data of each layer of slice to form a processing database, wherein the processing database comprises zone data of all slices, a storage format of any one zone in the processing database is YNXT, the Y represents numbers of the slices, N represents the quantity of the zones included in the Y layers of slices, X represents the number of a certain specific zone in the N zones of the Y layer of slices, and T represents the color of the Xth zone in the N zones of the Y layer of slices. Accordingto the software slicing method based on the colored photocuring 3D printer disclosed by the invention, the problem that colored products cannot be printed because an existing photocuring printer lacks colored slicing software is solved.

Owner:上海幻嘉信息科技有限公司

Magnetic resonance apparatus and method for simultaneous multi-slice imaging with arbitrary slice numbers

InactiveUS10126394B2Avoid restrictionsMeasurements using NMR imaging systemsElectric/magnetic detectionMulti sliceData set

Owner:SIEMENS HEALTHCARE GMBH

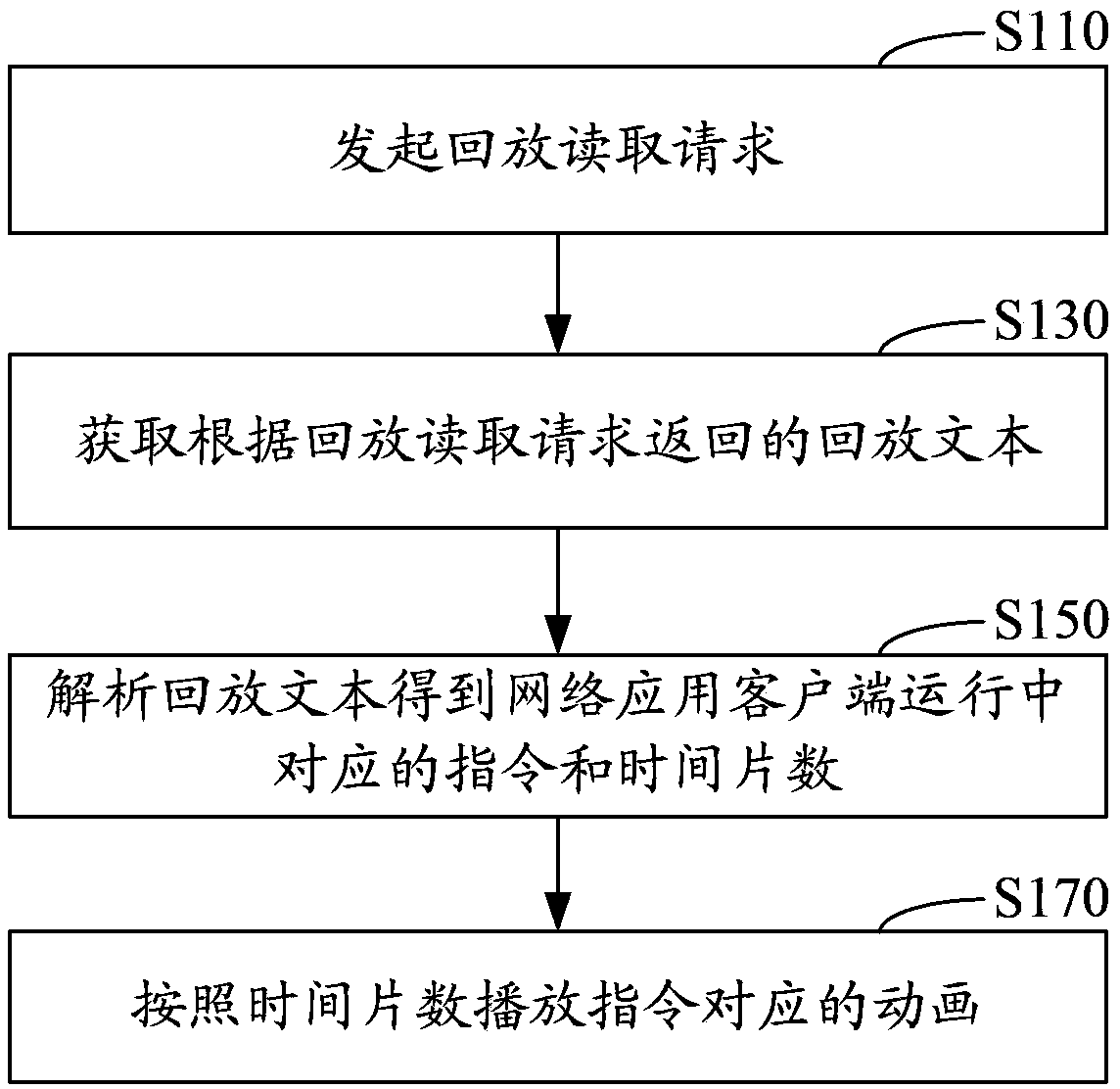

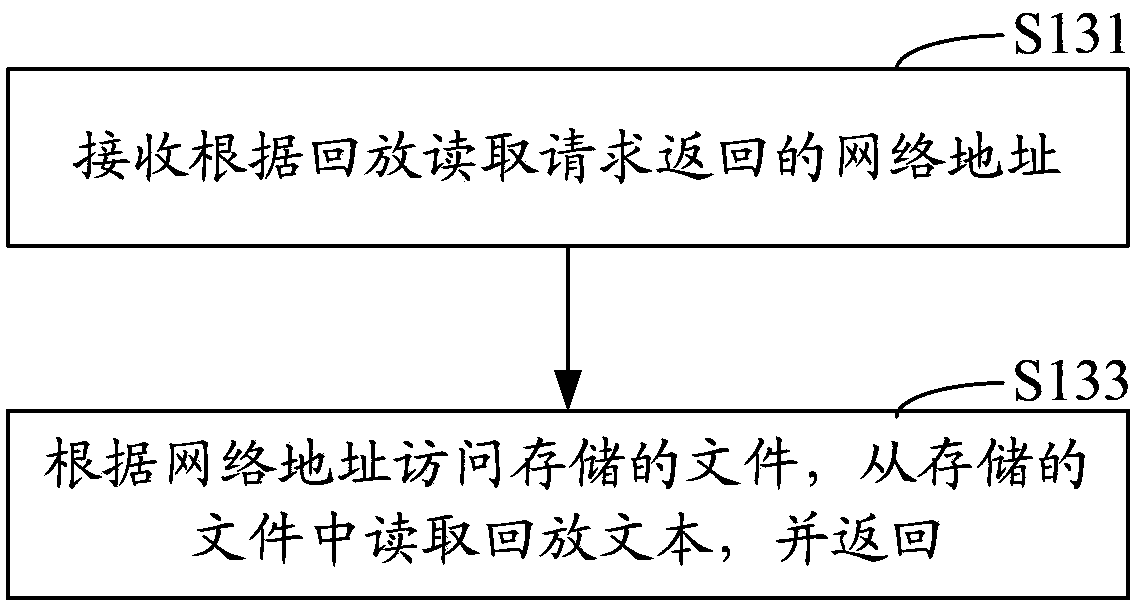

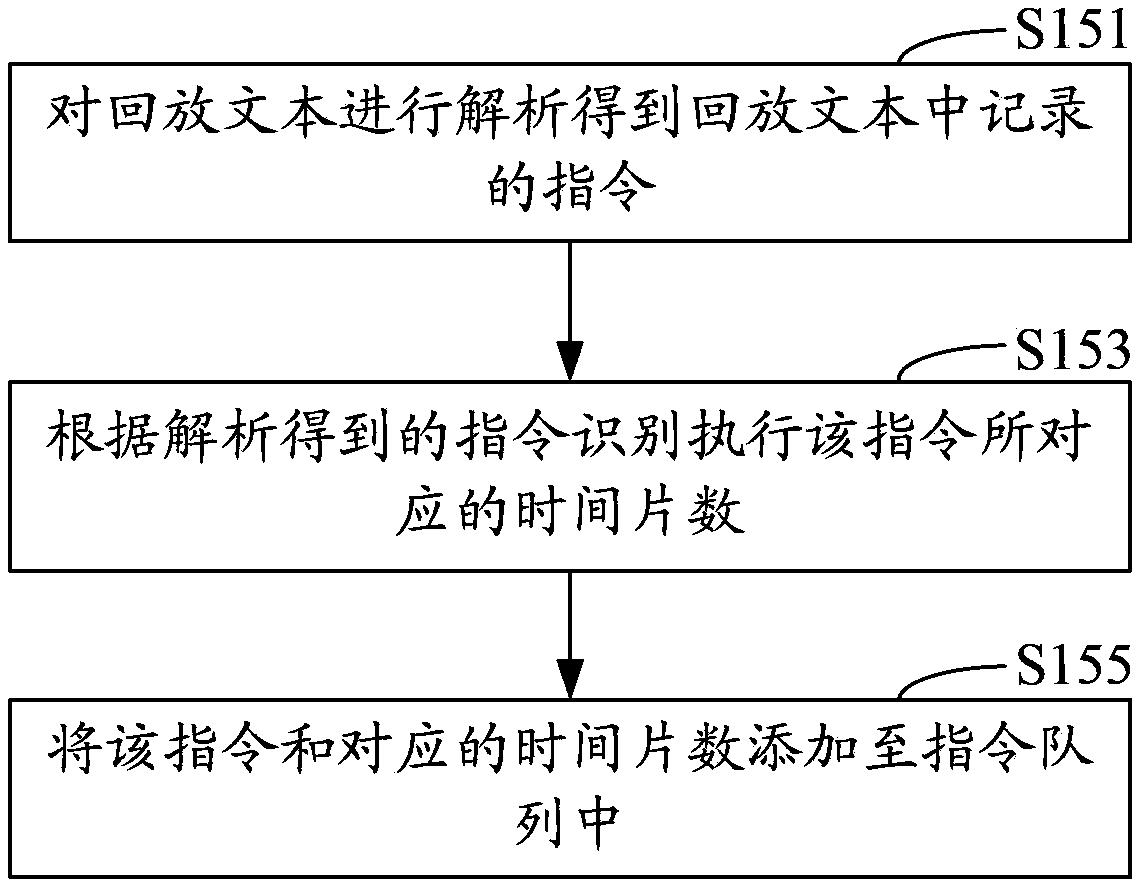

Playback method of network application client and system thereof

The invention provides a playback method of a network application client and a system thereof. The method comprises the following steps: a playback read request is initiated; a playback text returned according to the playback read request is obtained; the playback text is parsed to obtain a corresponding instruction and time slice number in running of the network application client; and an animation corresponding to the instruction is played according to the time slice number. The system comprises the network application client which comprises a request initiating module used for initiating the playback read request, a text obtaining module used for obtaining the playback text returned according to the playback read request, a parse module used for parsing the playback text to obtain the corresponding instruction and time slice number in the running of the network application client, and a play module used for playing the animation corresponding to the instruction according to the time slice number. By the method, playback in the running process can be realized in the lightweight network application client.

Owner:BOYAA ONLINE GAME DEV SHENZHEN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com