Preparation method of mesoporous carbon-based solid acid and mesoporous carbon-based solid acid prepared through method and application

A technology of mesoporous carbon and solid acid, which is applied in the field of mesoporous carbon, can solve the problems of high cost, cumbersome synthesis process, and increase the difficulty of mesoporous carbon, and achieve the effects of simple operation, cost reduction, and short preparation process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

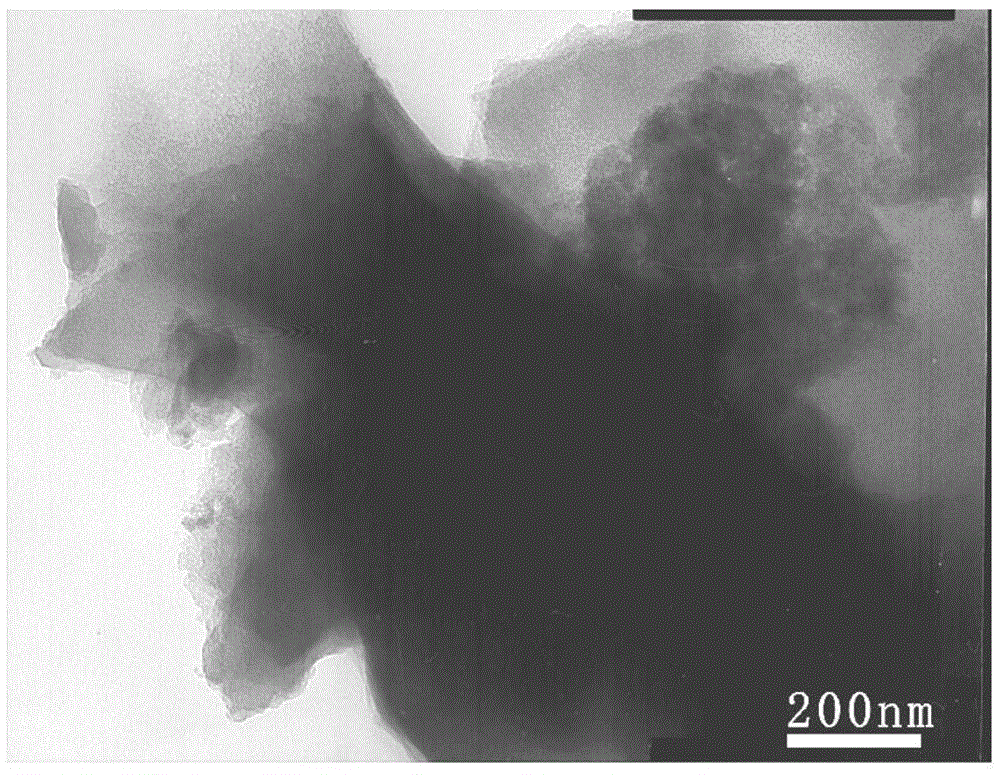

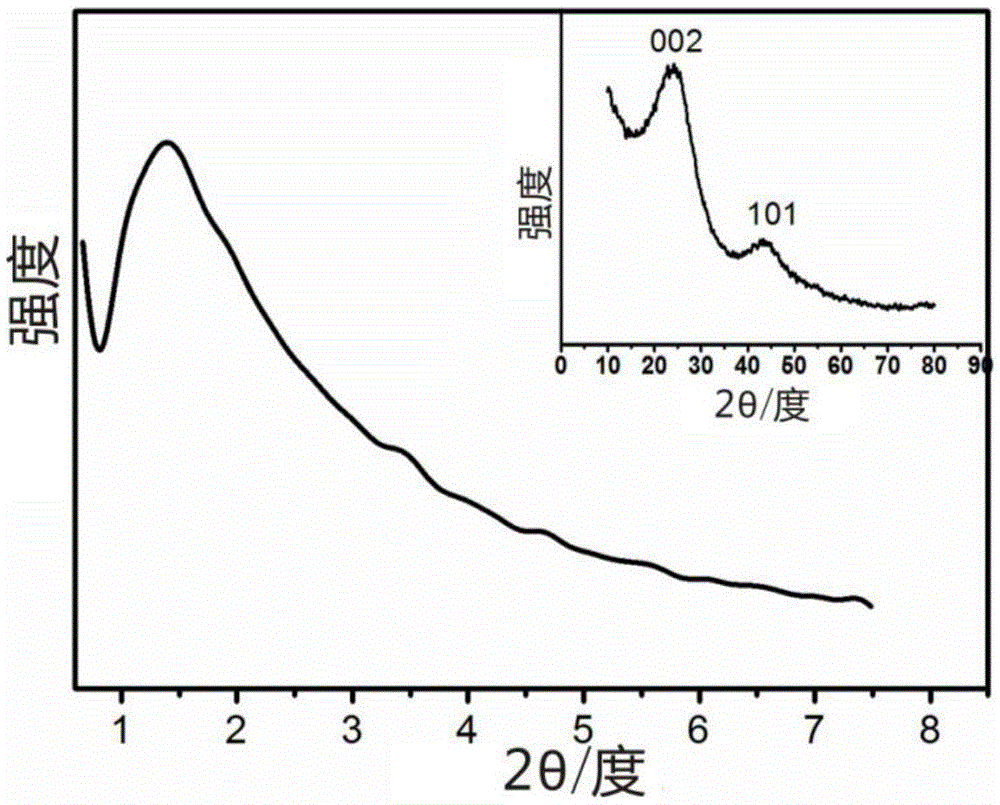

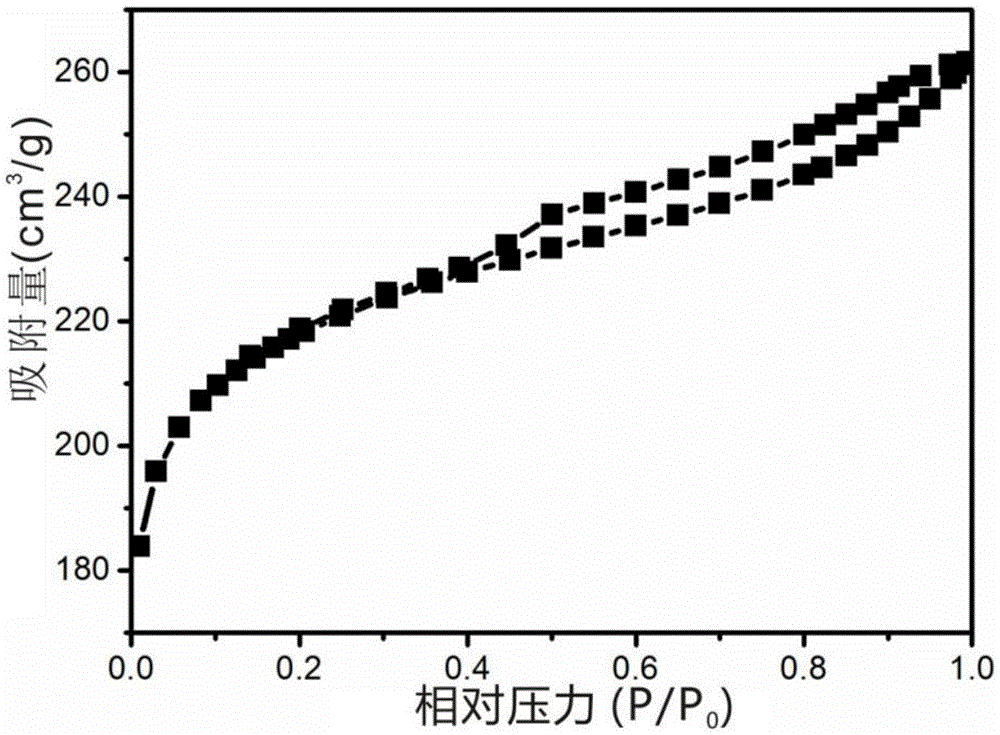

[0033] 3.42g of sucrose was weighed and dissolved in 40ml of water to obtain a precursor solution, and then 0.5g of P123 was dissolved in the precursor solution to obtain a mixed solution of the precursor and the template. Slowly add 5ml of concentrated sulfuric acid (98%) into the mixed solution of precursor and template, stir evenly, transfer the mixed solution of precursor and template to a petri dish, keep it at 40°C for 6h, then transfer to 100°C After keeping in the oven at ℃ for 6 hours, the mixture of precursor and template was obtained, and the obtained mixture was calcined in an inert atmosphere at a heating rate of 1 ℃ / min to 400 ℃ for 4 hours to remove the template, and the mesoporous carbon-based solid acid was obtained. The morphology of the product was characterized by transmission electron microscopy, as figure 1 As shown, the crystallinity of the product was characterized by X-ray diffraction pattern, as figure 2 As shown in the optical angle X-ray diffracti...

Embodiment 2

[0035] 3.42g of sucrose was weighed and dissolved in 40ml of water to obtain a precursor solution, and then 1.0g of F127 was dissolved in the precursor solution to obtain a mixed solution of the precursor and the template. Slowly add 5ml of concentrated phosphoric acid (85%) into the mixed solution of the precursor and the template, stir evenly, transfer the mixed solution of the precursor and the template to a petri dish, keep it at a temperature of 50°C for 6h, and then transfer to 100°C After keeping in the oven at ℃ for 6 hours, the mixture of precursor and template was obtained, and the obtained mixture was calcined in an inert atmosphere at a heating rate of 1 ℃ / min to 400 ℃ for 4 hours to remove the template, and the mesoporous carbon-based solid acid was obtained. The morphology and crystallinity of the product are similar to those obtained in Example 1.

Embodiment 3

[0037] 3.42g of sucrose was weighed and dissolved in 40ml of water to obtain a precursor solution, and then 1.5g of F108 was dissolved in the precursor solution to obtain a mixed solution of the precursor and the template. Slowly add 5ml of concentrated phosphoric acid (85%) into the mixed solution of precursor and template, stir evenly, transfer the mixed solution of precursor and template to a Petri dish, keep it at 60°C for 6h, then transfer to 100°C After keeping in the oven at ℃ for 6 hours, the mixture of precursor and template was obtained, and the obtained mixture was calcined in an inert atmosphere at a heating rate of 1 ℃ / min to 400 ℃ for 4 hours to remove the template, and the mesoporous carbon-based solid acid was obtained. The morphology and crystallinity of the product are similar to those obtained in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com