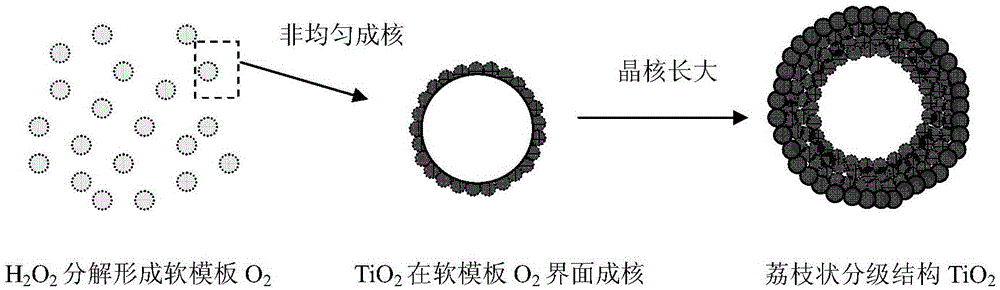

Preparation method of litchi-like hierarchical-structure {001}-surface-exposed TiO2 powder

A hierarchical structure, lychee technology, applied in the field of photocatalysis, can solve problems such as restricted use, and achieve the effects of easy control, easy implementation and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

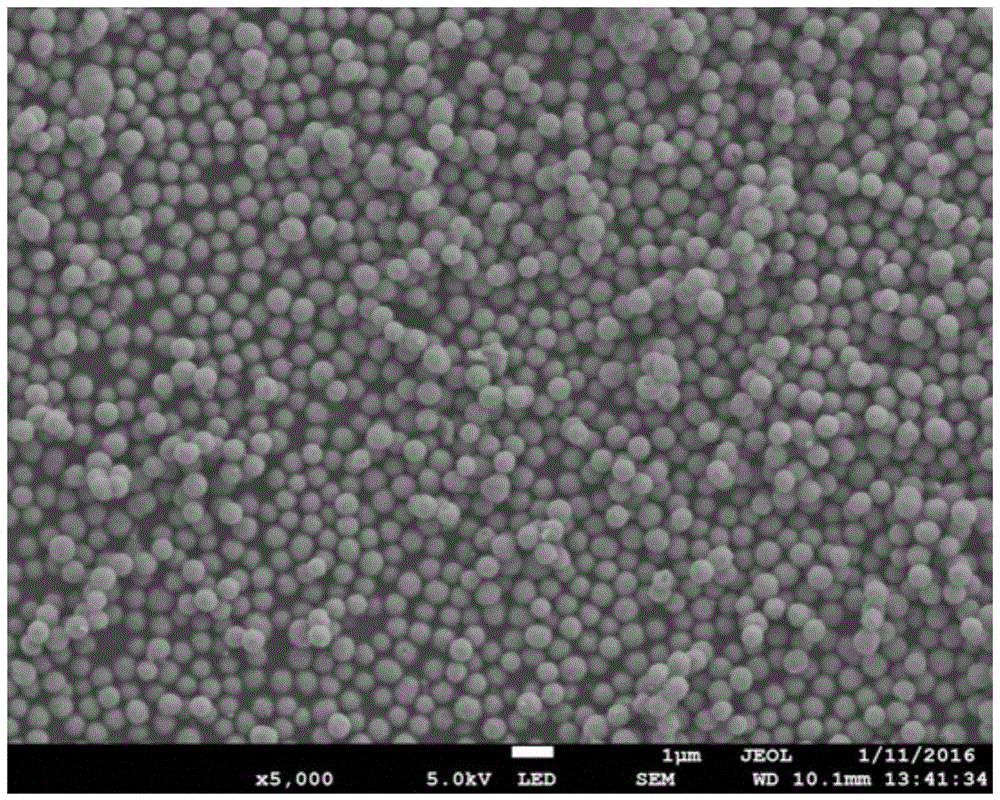

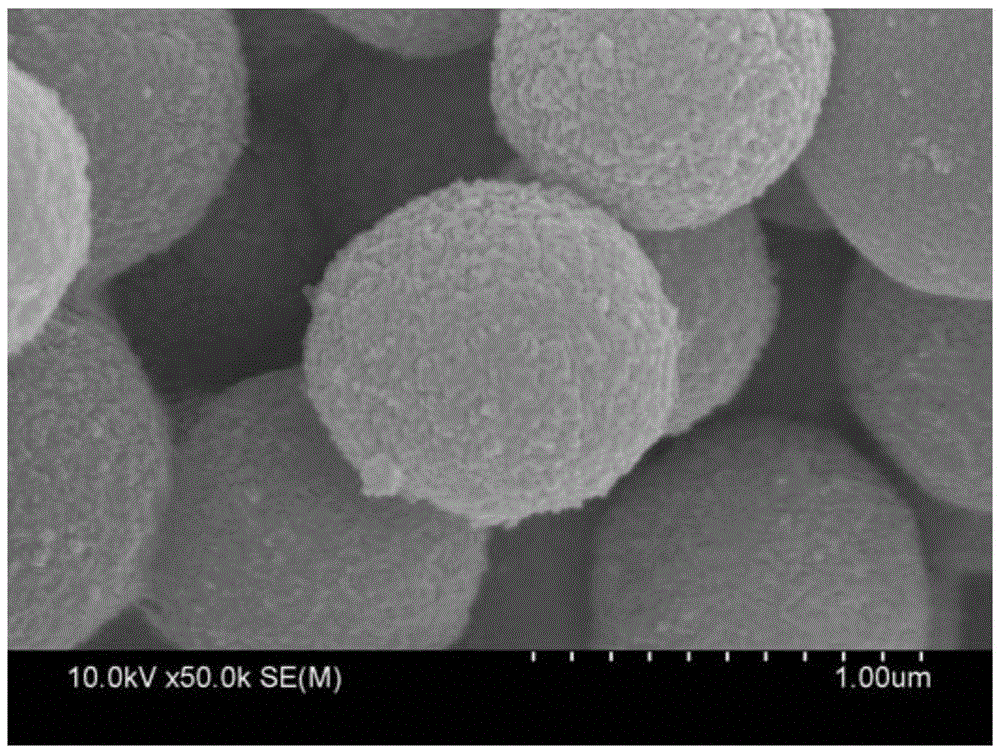

Embodiment 1

[0031] Take 1.58 grams of potassium titanium oxalate, add 30 ml of deionized water, slightly heat and stir for 15 min, and prepare a potassium titanium oxalate solution with a concentration of 0.15 mol / L. Continue to stir after dissolving, add 30ml of 30% hydrogen peroxide while stirring, and stir at room temperature for 30min. After the above steps are completed, put the solution into an airtight container and let it stand for 10 h. Add 37% concentrated hydrochloric acid to it while stirring after 10 hours, transfer it to a reaction kettle containing a polytetrafluoroethylene liner after stirring for 5 minutes, and carry out hydrothermal reaction for 12 hours, and the hydrothermal temperature is 120°C ~ 150°C. After the completion of the hydrothermal reaction, cool to room temperature and wash the precipitate 5 times with deionized water until the pH is neutral, and then wash 5 times with absolute ethanol. Place it in an oven for drying at a temperature of 80°C±5°C, and fin...

Embodiment 2

[0033] Potassium titanium oxalate solution was prepared with deionized water, slightly heated and stirred for 15mim, and potassium titanium oxalate solution was prepared with a concentration of 0.10mol. Continue to stir after dissolving, add 30ml of 30% hydrogen peroxide while stirring, and stir at room temperature for 30min. After the above steps are completed, put the solution into an airtight container and let it stand for 10 h. Add 37% concentrated hydrochloric acid to it while stirring after 10 hours, transfer it to a reaction kettle containing a polytetrafluoroethylene liner after stirring for 5 minutes, and carry out hydrothermal reaction for 12 hours, and the hydrothermal temperature is 120°C ~ 150°C. After the completion of the hydrothermal reaction, cool to room temperature and wash the precipitate 5 times with deionized water until the pH is neutral, and then wash 5 times with absolute ethanol. Place it in an oven for drying at a temperature of 80°C±5°C, and final...

Embodiment 3

[0035] Potassium titanium oxalate solution was prepared with deionized water, slightly heated and stirred for 15mim, and potassium titanium oxalate solution was prepared with a concentration of 0.25mol. Continue to stir after dissolving, add 30ml of 30% hydrogen peroxide while stirring, and stir at room temperature for 30min. After the above steps are completed, put the solution into an airtight container and let it stand for 10 h. Add 37% concentrated hydrochloric acid to it while stirring after 10 hours, transfer it to a reaction kettle containing a polytetrafluoroethylene liner after stirring for 5 minutes, and carry out hydrothermal reaction for 12 hours, and the hydrothermal temperature is 120°C ~ 150°C. After the completion of the hydrothermal reaction, cool to room temperature and wash the precipitate 5 times with deionized water until the pH is neutral, and then wash 5 times with absolute ethanol. Place it in an oven for drying at a temperature of 80°C±5°C, and final...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com