Method for preparing metal organic framework material

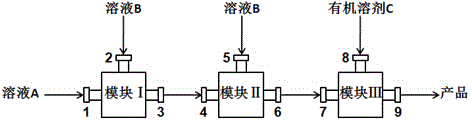

A metal-organic framework and organic solvent technology, which is applied in the field of preparing metal-organic framework materials using microchannel reactors, can solve the problems of affecting the production efficiency and performance of materials, consuming organic solvents, and long processing time, etc., and achieves good activation effects. Effects of shortened reaction time and high material handling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

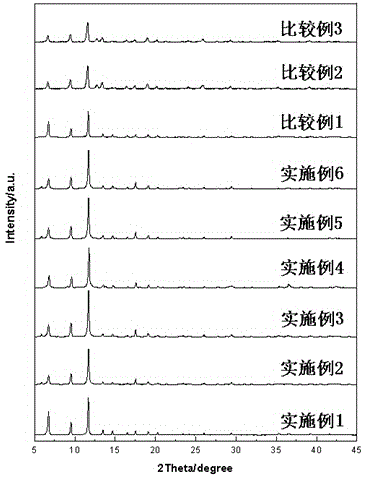

Embodiment 1

[0035] Dissolve 12.1 g of copper nitrate trihydrate in 500 ml of ethanol to form liquid A, and dissolve 10.5 g of trimesic acid in 500 ml of ethanol to form liquid B. The flow rate of liquid A is 5 μl / min, which is sent into module I from feed port 1, while the flow rate of liquid B is 5 μl / min, which is injected into module I from feed port 2, wherein the temperature of module I is 40°C and the pressure is 0.1MPa, liquid A and liquid B are uniformly mixed in module I to generate a feed liquid containing Cu-MOFs seed crystals, and the residence time is 180s. The feed liquid containing Cu-MOFs seed crystals is sent into the microchannel reactor module II from the feed port 4 at a flow rate of 10 μl / min, and the remaining B liquid is sent into the microchannel reactor from the feed port 5 at a flow rate of 5 μl / min In module II, the temperature of module II is 80°C, the pressure is 0.1MPa, and the residence time is 200s. After reacting for a certain period of time, the product ...

Embodiment 2

[0037] Dissolve 121g of copper nitrate trihydrate in 500ml of ethanol to form liquid A, and dissolve 210g of trimesic acid in 500ml of ethanol to form liquid B. The flow rate of liquid A is 200 μl / min, which is sent into module I from feed port 1, while the flow rate of liquid B is 200 μl / min, which is injected into module I from feed port 2, where the temperature of module I is 70°C and the pressure 1.0MPa, liquid A and liquid B are uniformly mixed in module I to generate a feed liquid containing Cu-MOFs seed crystals, and the residence time is 30s. The feed liquid containing Cu-MOFs seed crystals is sent into the microchannel reactor module II from the feed port 4 at a flow rate of 400 μl / min, and the remaining liquid B is sent into the microchannel reactor from the feed port 5 at a flow rate of 200 μl / min In module II, the temperature of module II is 150°C, the pressure is 1MPa, and the residence time is 60s. After reacting for a certain period of time, the product feed li...

Embodiment 3

[0039] Dissolve 60.5g of copper nitrate trihydrate in 500ml of ethanol to form liquid A, and dissolve 105g of trimesic acid in 500ml of ethanol to form liquid B. The flow rate of liquid A is 100 μl / min, and it is sent into module I from feed port 1, while the flow rate of liquid B is 100 μl / min, and it is injected into module I from feed port 2, wherein the temperature of module I is 60°C and the pressure is 0.5MPa, liquid A and liquid B are uniformly mixed in module I to generate a feed liquid containing Cu-MOFs seed crystals, and the residence time is 120s. The feed liquid containing Cu-MOFs seed crystals is sent into the microchannel reactor module II from the feed port 4 at a flow rate of 200 μl / min, and the remaining liquid B is sent into the module II from the feed port 5 at a flow rate of 100 μl / min , where the temperature of module II is 120°C, the pressure is 0.5MPa, and the residence time is 150s. After reacting for a certain period of time, the product feed liquid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com