High-temperature polymer-matrix composite coating and protection and method of preventing coating from being exposed to high temperatures

A high-temperature polymerization and compound technology, used in vacuum evaporation plating, coating, melting spray plating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

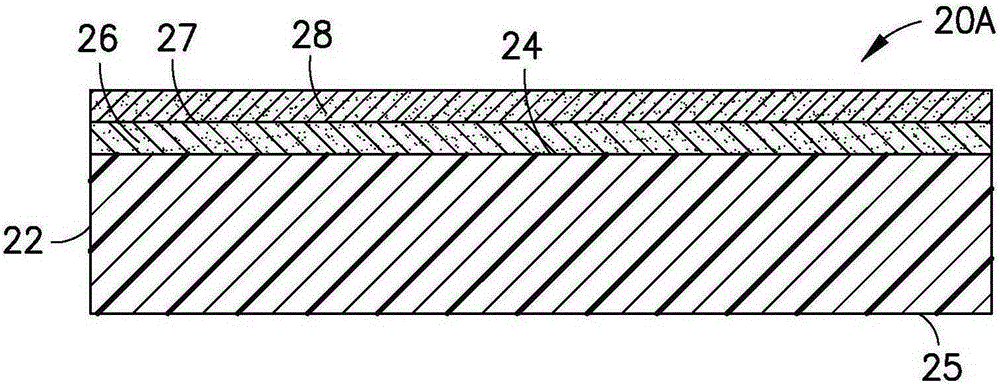

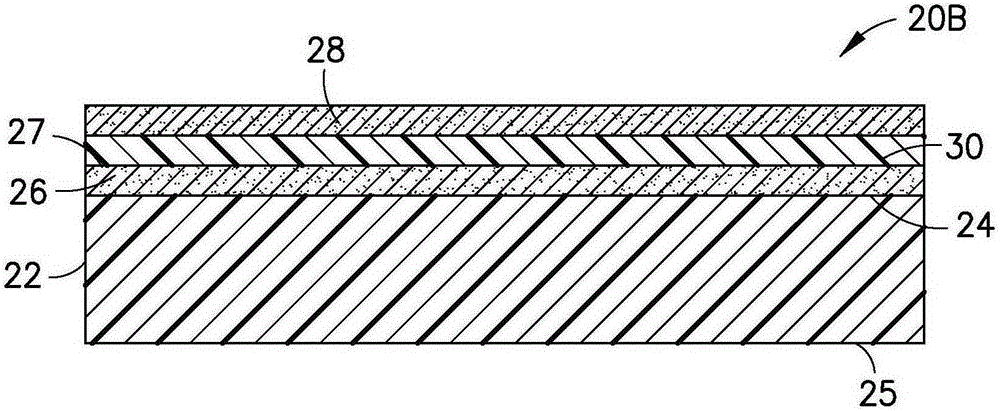

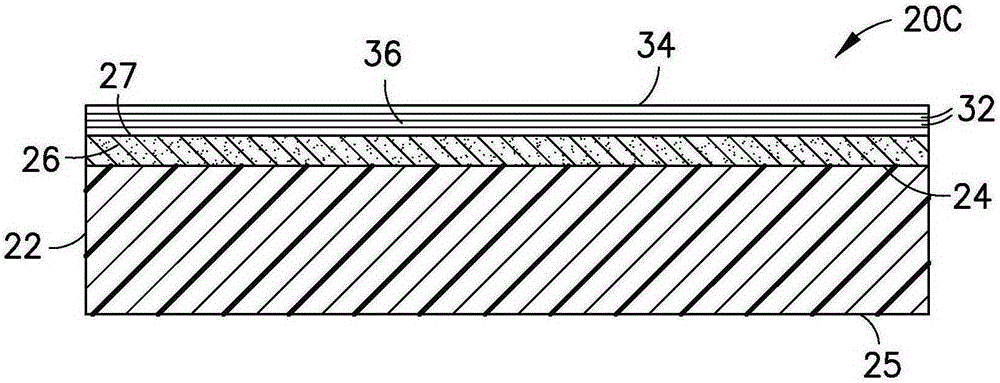

[0020] In the detailed description below, various embodiments of HTPMC substrates coated with conductive carbon-based barrier coatings and related methods for protecting HTPMC substrates from exposure to high temperatures in the presence of air are described with reference to aerospace structures. , thus illustrating the basic principles of the present disclosure. Those skilled in the art will recognize that the present disclosure may be practiced in other simulated applications or environments of the illustrative embodiments and / or with other simulated variations or equivalents of the illustrative embodiments. For example, conductive carbon-based barrier coatings and methods for protecting HTPMC substrates from exposure to high temperatures in the presence of air can be applied to engine applications in the automotive industry or oil well applications in the oil drilling industry that are exposed to high temperatures. Those of ordinary skill in the art will recognize and appr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com