Modified PCT resin compound and preparation method thereof

A resin compound and modification technology, which is applied in the field of modified PCT resin compound and its preparation, can solve the problems of poor processing fluidity, unstable injection pressure, poor processing performance, etc., and achieve the improvement of tensile strength and the production of raw materials The effect of simplicity and good processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] In the preparation process of the above-mentioned wholly aromatic liquid crystal polyester resin, a solution polycondensation method or a bulk polycondensation method may be used. In order to promote the polycondensation reaction, an acylating agent can be used to pretreat the raw materials during the synthesis of the wholly aromatic liquid crystal polyester prepolymer, especially an acetylating agent can be used for pretreatment.

[0033] In the above-mentioned solid-state polycondensation reaction (solid-state polycondensation reaction), it is necessary to provide appropriate heat to the wholly aromatic liquid crystal polyester prepolymer. The specific heat supply can be through methods such as heating plates, hot air, and high-temperature fluids, and in order to remove solid-state polycondensation reactions. By-products can be removed with an inert gas purge or vacuum.

[0034] In any embodiment, the first filler is at least one of glass fiber, whisker, polytetrafluo...

Embodiment 1

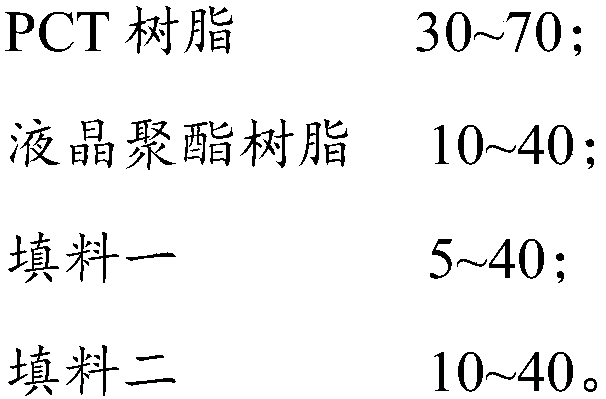

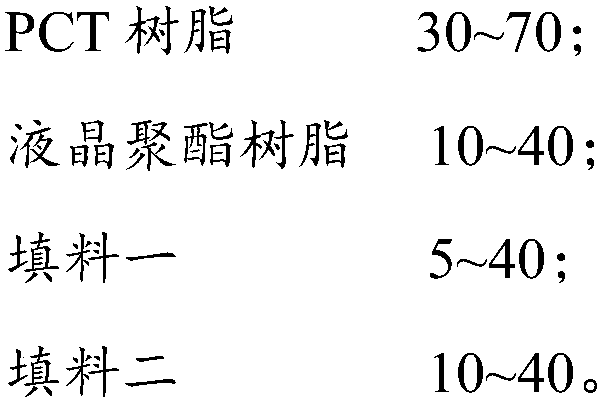

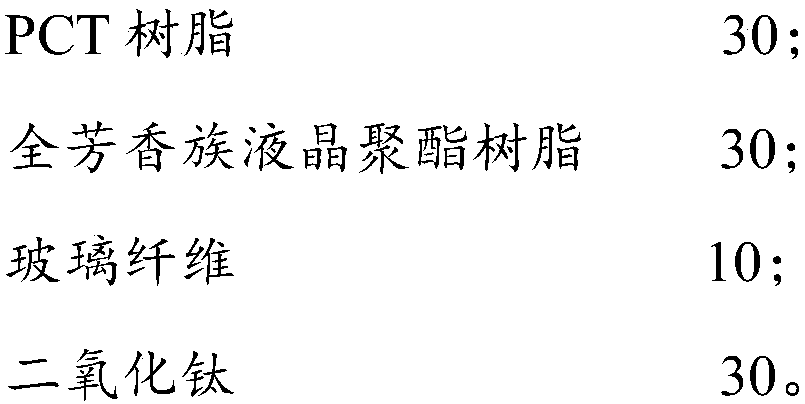

[0050] A modified PCT resin composite, comprising the following components in parts by weight:

[0051]

[0052] The preparation method of the modified PCT resin compound that embodiment 1 provides is as follows:

[0053]Step S01, 30 parts of PCT resin (produced by American Eastman Chemical Company), 30 parts of fully aromatic liquid crystal polyester resin (produced by Jiangsu Water Special Materials Co., Ltd.), 30 parts of titanium dioxide, and 10 parts of glass fiber were placed in Dry at 130°C for 4 hours;

[0054] Step S02, putting the dried PCT resin, glass fiber, titanium dioxide and wholly aromatic liquid crystal polyester resin into an automatic mixer and mixing evenly to obtain a mixed material;

[0055] Step S03, putting the mixture obtained in step S02 into a twin-screw extruder for melting and kneading, and then extruding, drawing, cooling, and granulating to obtain a modified PCT resin compound.

Embodiment 2

[0057] A modified PCT resin composite, comprising the following components in parts by weight:

[0058]

[0059] The preparation method of the modified PCT resin compound that embodiment 2 provides is as follows:

[0060] Step S01, 40 parts of PCT resin (produced by American Eastman Chemical Company), 20 parts of fully aromatic liquid crystal polyester resin (produced by Jiangsu Water Special Materials Co., Ltd.), 30 parts of titanium dioxide, and 10 parts of glass fiber were placed in Dry at 130°C for 4 hours;

[0061] Step S02, putting the dried PCT resin, glass fiber, titanium dioxide and wholly aromatic liquid crystal polyester resin into an automatic mixer and mixing evenly to obtain a mixed material;

[0062] Step S03, putting the mixture obtained in step S02 into a twin-screw extruder for melting and kneading, and then extruding, drawing, cooling, and granulating to obtain a modified PCT resin compound.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com