Water-based woodware anti-bleeding seal primer, and preparation method and application thereof

A sealing primer, water-based technology, applied in the direction of coating, etc., can solve the problems of affecting the coating effect, emulsion breaking, paint film peeling, etc., to increase adhesion and sealing effect, increase cross-linking density, and improve sealing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

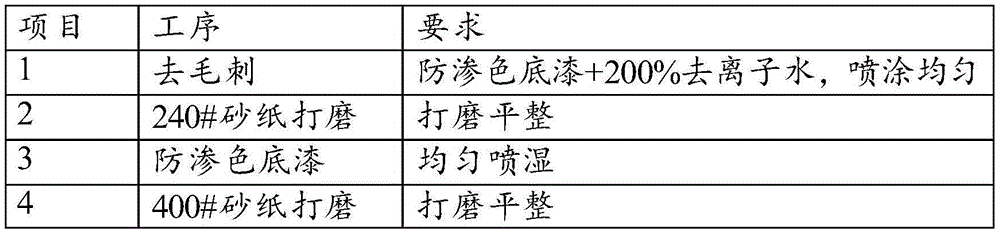

preparation example Construction

[0049] The present invention also provides a kind of preparation method of water-based wood sealing primer, comprising the following steps:

[0050] 1) adding film-forming aids, defoamers and wetting agents to the water-based hydroxyacrylic resin, stirring and dispersing to obtain the first mixture;

[0051] 2) Add grinding aid, tannic acid polymerization inhibitor, deionized water and thickener to the first mixture obtained in the above steps, and continue to stir and disperse to obtain component A;

[0052] 3) After combining component A and component B obtained in the above steps, water-based wood sealing primer is obtained;

[0053] The component B is an aqueous HDI trimer.

[0054] In the preparation method of the present invention, the specific preferred scheme of the raw material, and the preferred numerical value of the added number of parts are consistent with the specific preferred scheme of the components in the aforementioned water-based wood sealer primer, and th...

Embodiment 1

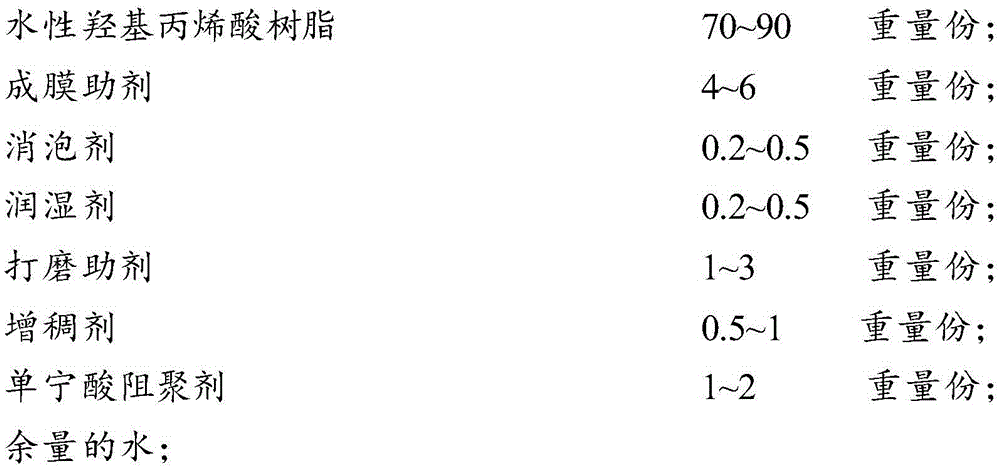

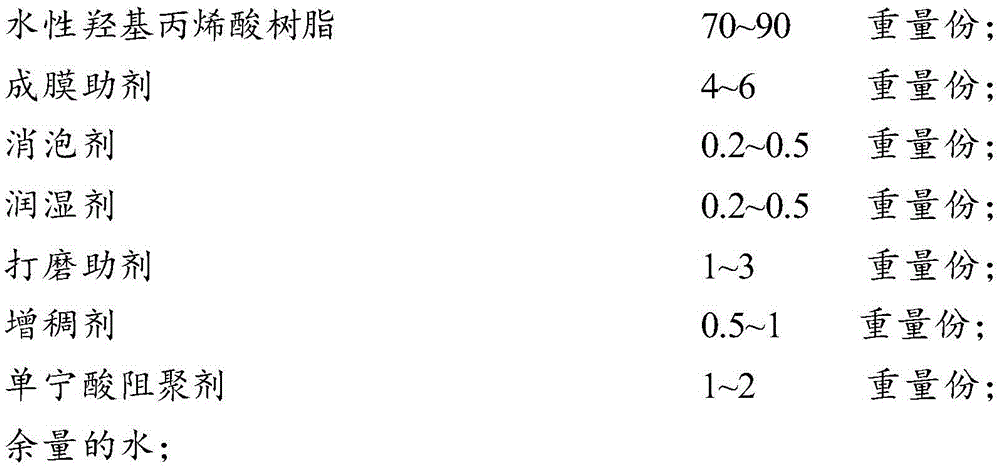

[0070] An anti-bleeding color sealing primer, comprising two components A and B, the mass ratio of component A to component B is 100:5, wherein component A comprises the following components according to the mass fraction:

[0071] Water-based hydroxyacrylic resin (A-450): 70%, dipropylene glycol methyl ether: 3%, dipropylene glycol butyl ether: 2%, BYK028: 0.2%, Tego 270: 0.3%, zinc stearate: 2%, RM -8W: 0.5%, haloxL44: 1%, deionized water: 21%.

[0072] (1) Add dipropylene glycol methyl ether, dipropylene glycol butyl ether, BYK028, and Tego 270 to A-450 in sequence, and disperse for 20 minutes at 2000 rpm;

[0073] (2) Then reduce the rotation speed to 1000 rpm, add zinc stearate, haloxL44, deionized water and thickener in sequence, and disperse for 30 minutes to obtain component A.

[0074] When used, the mass ratio of component A and component B is 100:5, and after uniform mixing, the anti-bleeding color sealing primer is obtained

Embodiment 2

[0076] An anti-bleeding color sealing primer, comprising two components A and B, the mass ratio of component A to component B is 100:5, wherein component A comprises the following components according to the mass fraction:

[0077] Water-based hydroxyacrylic resin (A-450): 80%, dipropylene glycol methyl ether: 4%, dipropylene glycol butyl ether: 2%, BYK028: 0.3%, Corning H140: 0.3%, zinc stearate: 2%, RM -8W: 0.5%, haloxL66: 2%, deionized water: 8.9%.

[0078] (1) Add dipropylene glycol methyl ether, dipropylene glycol butyl ether, BYK028, and Corning H140 to A-450 in sequence, and disperse for 20 minutes at 2000rpm;

[0079] (2) Then reduce the rotational speed to 1000 rpm, add zinc stearate, haloxL66, deionized water and thickener in sequence, and disperse for 30 minutes to obtain component A.

[0080] When used, the mass ratio of component A and component B is 100:5, and after uniform mixing, the anti-bleeding color sealing primer is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com