Process for recovering light hydrocarbons from crude oil distillation device, as well as system

A technology of crude oil distillation and absorption stabilization system, which is applied in the process and system field of recovering light hydrocarbons in crude oil distillation equipment, and can solve problems such as short service life, corrosion, and large investment in compressors, and achieve the effect of easy promotion and small changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

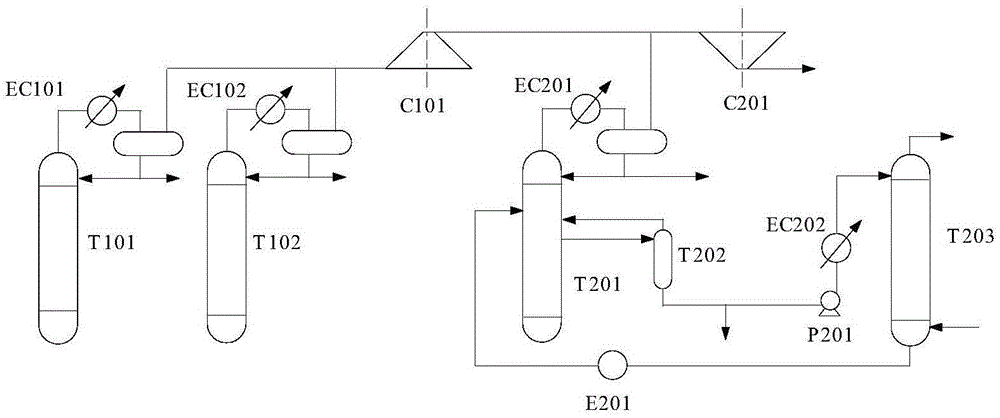

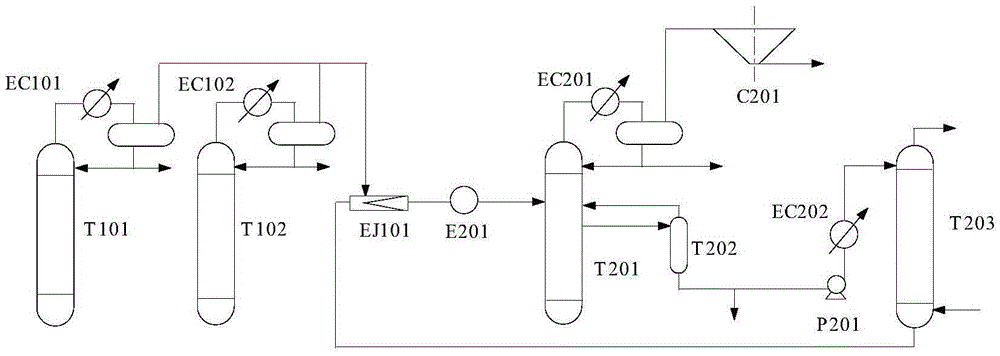

[0035] In this embodiment, the above-mentioned system for recovering light hydrocarbons in the crude oil distillation unit is used to recover light hydrocarbons, and the process flow is as follows:

[0036] The initial normal top gas is obtained through the initial distillation tower T101 of the crude oil distillation unit and the atmospheric tower T102 of the crude oil distillation unit, and the initial normal top gas enters the liquid gas jet pump EJ101 of the crude oil distillation unit; The rich absorption oil enters the liquid-gas jet pump EJ101 of the crude oil distillation unit under self-pressure to increase the pressure of the initial permanent top gas;

[0037] The pressurized gas and the rich absorption oil are heated by the rich absorption oil heat exchanger E201 of the catalytic cracking unit, and then enter the main fractionation tower T201 of the catalytic cracking unit under self-pressure; through the separation of the main fractionation tower T201 of the catalyti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com