Humidity-sensitive telescopic polyaniline conductive fiber and preparation method thereof

A conductive fiber, humidity-sensitive technology, applied in the direction of fiber type, fiber treatment, plant fiber, etc., can solve the problems of limited fiber stretch, reduced conductivity, short response time, etc., to improve the conductivity and increase the specific surface area. , the effect of ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

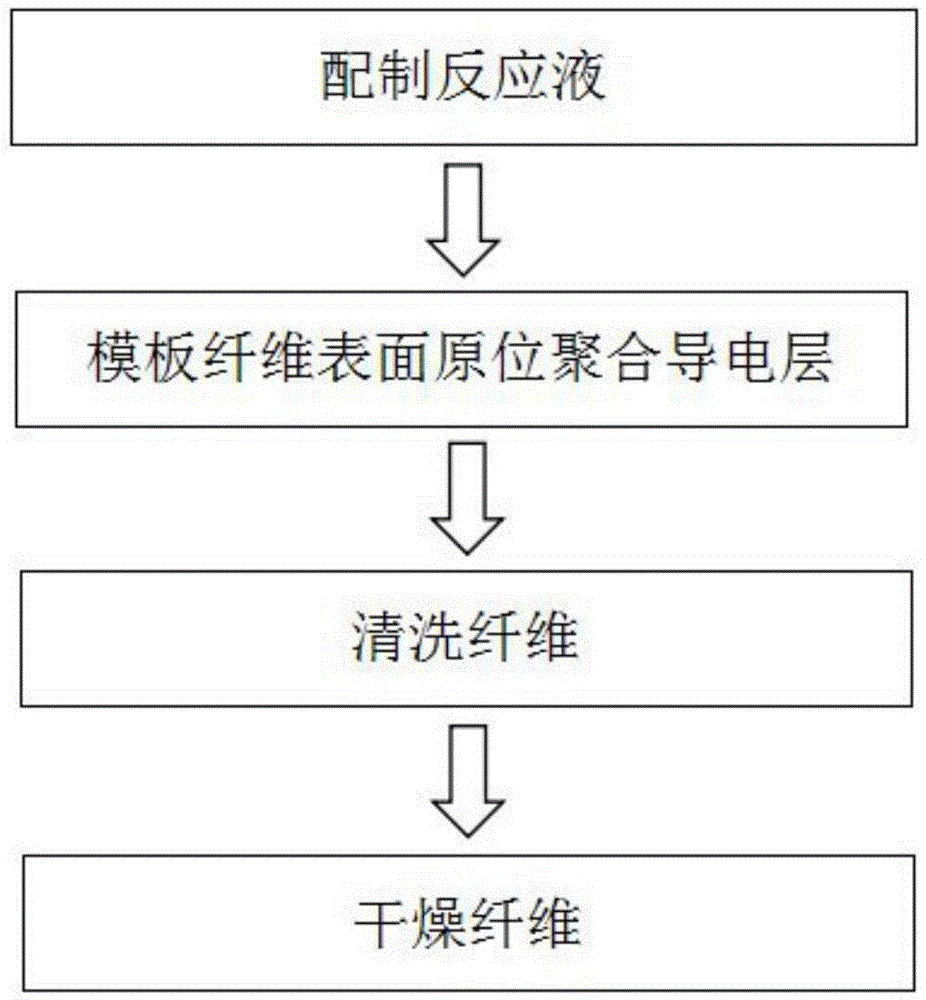

[0027] A kind of preparation method of moisture-sensitive stretchable polyaniline conductive fiber, comprises the following steps:

[0028] (1) Preparation of reaction solution: Weigh 5.0844 grams of sulfosalicylic acid and dissolve it in 100 milliliters of deionized water, stir with a magnetic stirrer for 5 to 10 minutes to dissolve the solvent evenly to obtain solution 1; weigh 9.128 grams of ammonium persulfate Add 100 ml of deionized water, then dropwise add 3.725 g of aniline, and stir with a magnetic stirrer until the solution becomes an emulsion to obtain solution 2;

[0029](2) In-situ polymerization conductive layer on the surface of the template fiber: the spandex core-spun cotton yarn is stretched and wound on the hollow support as the template fiber, and the hollow support wrapped with the template fiber is immersed in a beaker containing solution 2, and then dripped with a glue head. Add solution 1 dropwise to solution 2 by tube, and after solution 1 prepared in s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com