Resistance furnace

A resistance furnace and resistance wire technology, applied in the direction of electric furnace heating, furnace, furnace type, etc., can solve the problems of increasing the preparation cost of the heating furnace and the difficulty of accurate current control, and achieve the effect of reducing the preparation cost and blocking the loss of energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

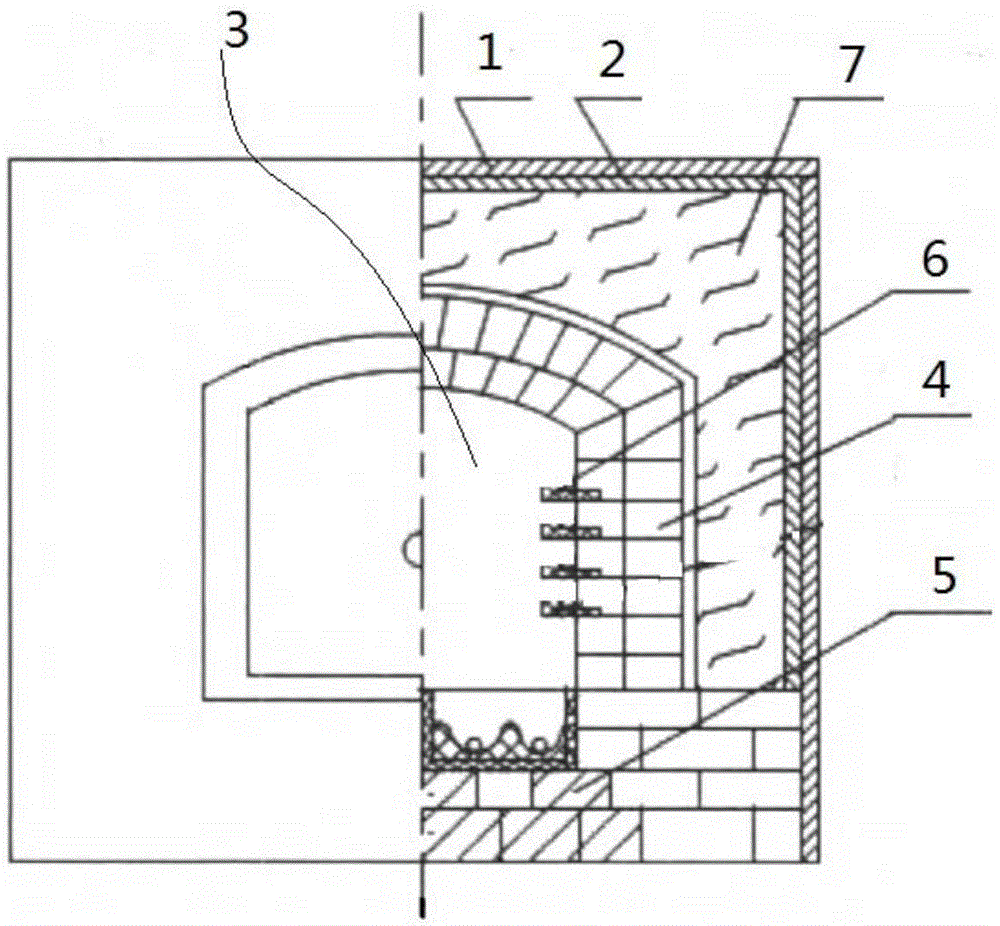

[0012] This example figure 1 and figure 2 as shown,

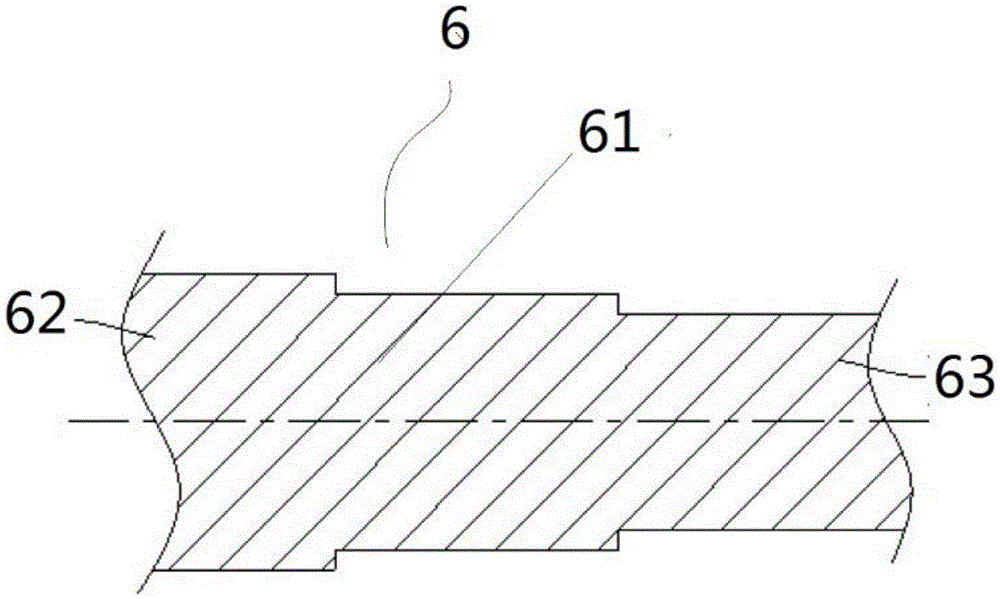

[0013] A resistance furnace, which includes a furnace shell 1, the inner surface of the furnace shell 1 is provided with a heat-insulating fiber felt 2 on the side wall, and the middle part of the furnace shell 1 is provided with a furnace body 3 for storing materials. The furnace body 3 is made of lightweight refractory bricks 4, the bottom of the furnace body 3 is laid with several layers of heavy refractory bricks 5, and the space between the heat-insulating fiber mat 2 and the furnace body 3 is filled with expansion Perlite, said lightweight refractory bricks 4 are provided with resistance wires 6 at intervals, said resistance wires 6 include a resistance wire body 61, said resistance wire body 61 is cylindrical, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com