A non-contact temperature parameter extraction device in an ultra-high temperature environment

A temperature parameter, non-contact technology, applied in thermometers, measuring devices, electrical devices, etc., can solve problems such as inaccurate test results, insufficient dynamic response, complex processing technology, etc., and reduce the adaptability requirements of high temperature environments. The effect of high temperature parameter accuracy and obvious change of resonance frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

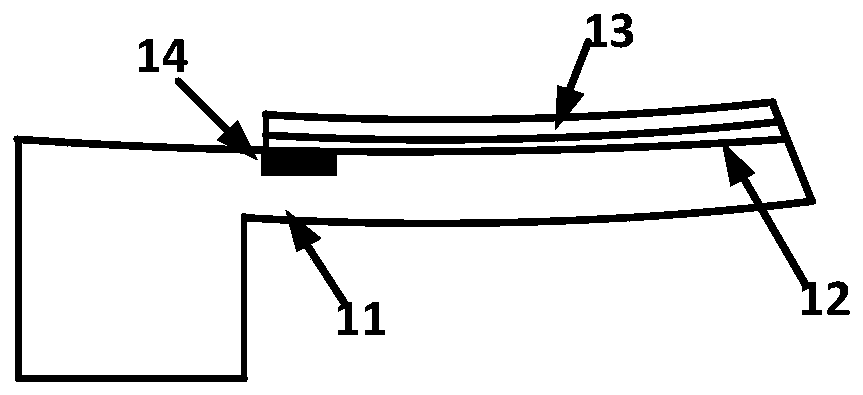

[0034] Such as figure 1Shown is a piezoresistive composite beam temperature sensor prepared by surface technology. When the temperature changes, the double-layer material of the composite cantilever 11 bends due to the mismatch of thermal expansion coefficients to form thermal stress. Bending under the action of stress generates shear stress on the contact surface of the aluminum film 13 and the silicon film 12, so that the resistance value of the piezoresistor 14 located on the root surface of the silicon cantilever beam changes. The change of the piezoresistive 14 is read through the Wheatstone bridge, and the change of the stress is used to characterize the change of the temperature. The preparation of the temperature sensor is relatively complicated, in which the cantilever beam structure is prepared by epitaxial monocrystalline silicon surface micromachining (MEMS), and the Wheatstone bridge input needs to be powered by pulsed current, and the peak operating temperature i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com