Automatic titration apparatus for analytical instrument

A technology of automatic titration and titration tank, which is applied in the direction of chemical analysis by titration method, can solve the problems of damage to devices in the titration tank, easy residual waste liquid, leakage, etc., and achieve low production and assembly costs, simple liquid inlet and discharge process, The effect of low system cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

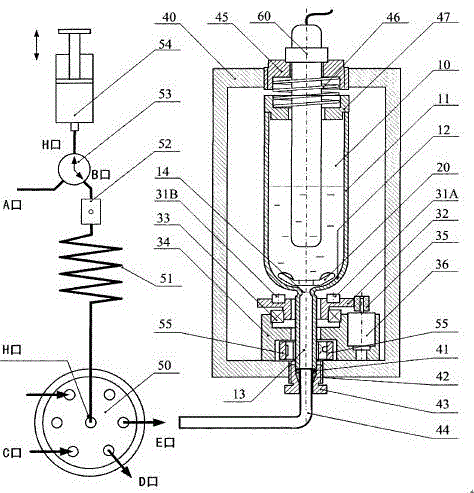

[0026] Such as figure 1 Shown, a kind of automatic titration device that adopts OPR electrode as the titration endpoint judgment is used in the titration of ferrous ammonium sulfate to potassium dichromate, and described automatic titration device comprises: titration cell 10, magnetic stirrer 20, circular Strong magnetic blocks 31A and 31B, large gear turntable 32, bearing pair 33, electromagnetic stirring device shell frame 34, pinion gear 35, motor 36, fastening frame 40, O-ring seal 41, clamp 42, lower supporting knob 43 , Teflon hard tube 44, compression knob 45, compression spring 46, titration tank cover 47, multi-position valve 50, liquid storage ring 51, liquid inlet liquid detector 52, two-position three-way valve 53 and plunger Pump 54 (stepping motor not shown), titration liquid detector 55 and ORP electrode 60.

[0027] The body 11 of the titration cell 10 adopts a cylindrical design with an open upper end, and the material is transparent, corrosion-resistant and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com