Construction method for noble metal hollow tube array-based ordered membrane electrode assemblies

A technology of noble metals and hollow tubes, applied in battery electrodes, nanotechnology for materials and surface science, circuits, etc., can solve problems such as easily damaged ordered structures and complicated preparation processes, and achieve improved catalytic activity and utilization. The effect of simple steps and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Such as Figure 8 As shown, this embodiment provides a method for constructing an ordered membrane electrode based on a noble metal hollow tube array, including steps:

[0049] Such as Figure 8 As shown, step 1) S11 is first performed to provide a substrate, and a zinc oxide seed layer is prepared on the substrate.

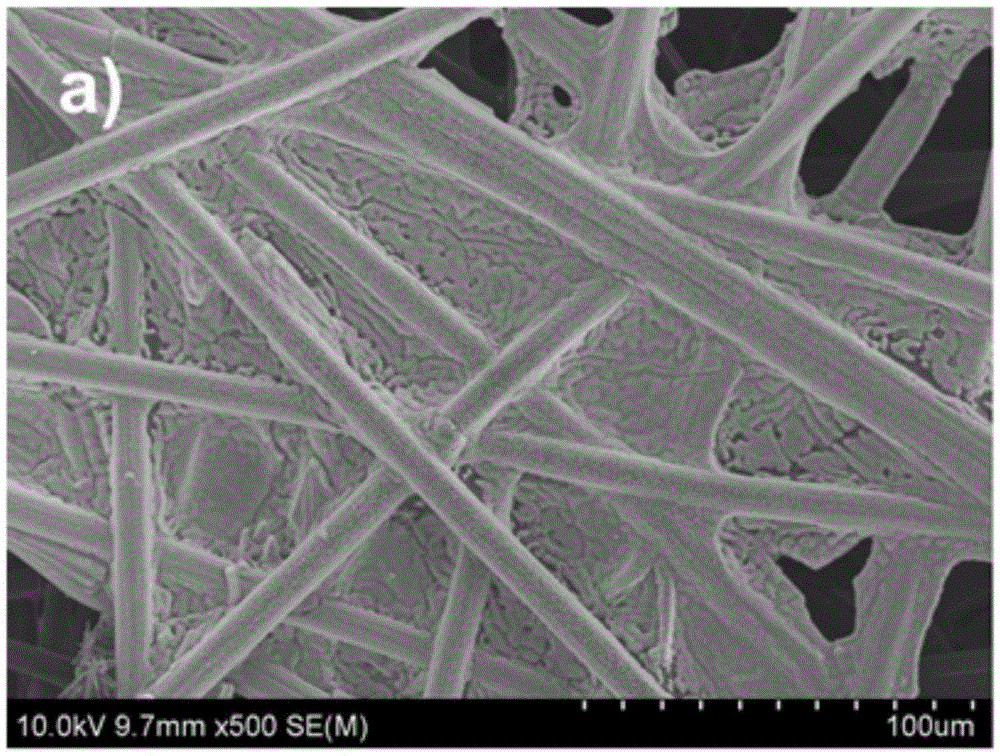

[0050] As an example, the substrate includes one of a silicon wafer, carbon paper, and carbon paper fabricated with a gas diffusion layer. In this embodiment, the substrate is carbon paper made with a gas diffusion layer, and the mass fraction of polytetrafluoroethylene in the gas diffusion layer of the carbon paper made with a gas diffusion layer is 10% to 30%, and The loading capacity of the gas diffusion layer is 1~2mg / cm 2 . Specifically, the carbon powder, the polytetrafluoroethylene dispersion liquid and the isopropanol aqueous solution are mixed, ultrasonically uniform, sprayed onto the carbon paper, and finally heat-treated to obtain the carbon...

Embodiment 2

[0075] This embodiment provides a method for constructing an ordered membrane electrode based on a noble metal hollow tube array, the basic steps of which are as in Embodiment 1, wherein, in this embodiment, Cu is used as a metal replacement agent to prepare a Pt nano-array structure and used as The cathode catalyst layer prepares an ordered membrane electrode, comprising the following steps:

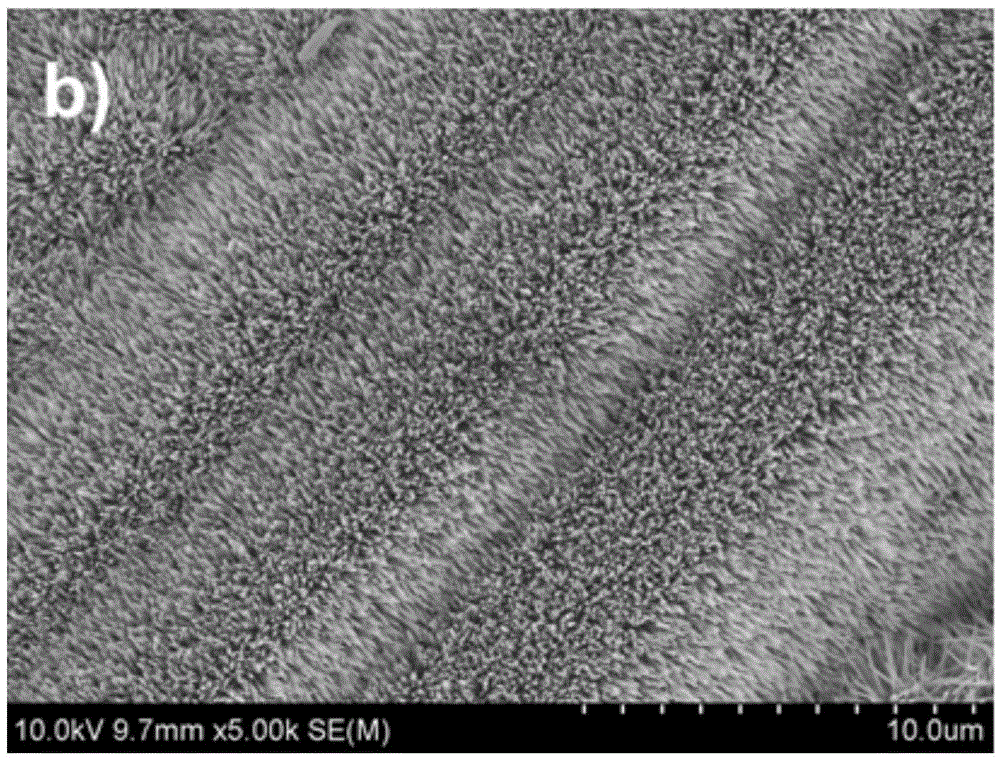

[0076] 1) Preparation of ZnO nano-arrays: ZnO nano-arrays were prepared on carbon paper prepared with GDL according to Example 1.

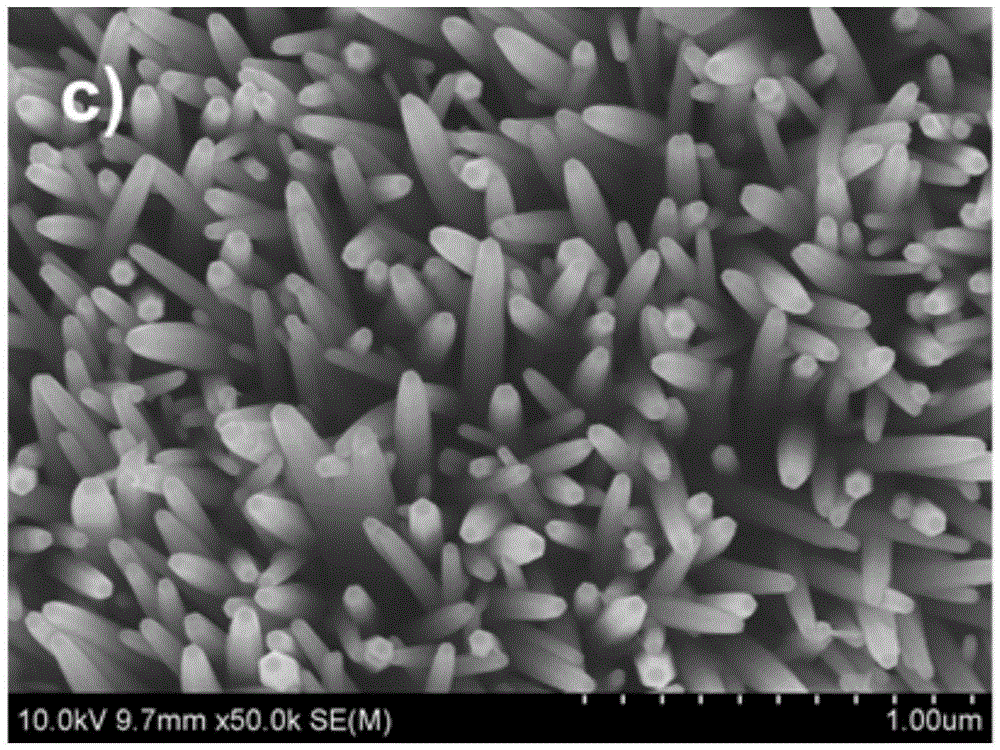

[0077] 2) Prepare a metal displacer on the ZnO nanoarray: use a magnetron sputtering apparatus to make a layer of Cu on the ZnO nanoarray as a metal displacer; the sputtering process is as follows: copper (purity is 99.99%) as the target material, DC power supply The power is 50W, and the sputtering time is 50s.

[0078] 3) Preparation of Pt nanoarrays on ZnO nanoarrays: Weigh 18.68 mg of K 2 PtCl 4 Dissolve in 300ml water, stir well to get K with a conc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Maximum power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com