a fermented dairy product

A technology for fermenting dairy products and strains, applied in dairy products, milk preparations, food ingredients, etc., can solve the problem of less high value-added products, improve endocrine status, increase blood pressure, and promote iron absorption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

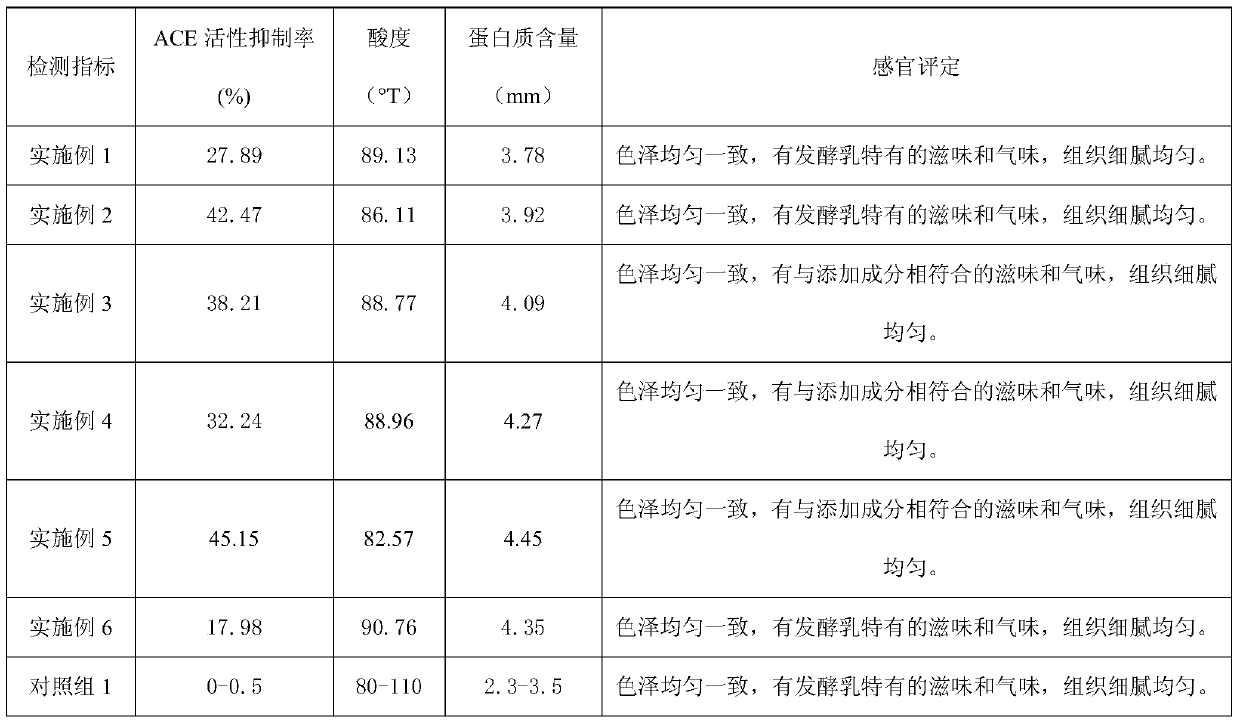

Examples

preparation example Construction

[0044] 1) Preparation of reaction solution

[0045] Take 20μL of inhibitor solution and add 120μL of 5mmol / L HHL solution. After mixing well, place it in a water bath at 37℃ to preheat for 5min. At the same time, take 20μL of ACE reagent and place it in a water bath at 37℃ to preheat it. Heat for 5 minutes; after preheating, mix the above-mentioned mixed solution and ACE reagent thoroughly as a sample group. The sample group was kept at 37°C for 60 minutes, and then 200 μL of 1 mol / L HCl was added to stop the reaction to obtain a reaction solution. After the reaction solution was filtered through a 0.45μm filter membrane, it was analyzed by HPLC.

[0046] Furthermore, 20 μL of the boric acid buffer was used instead of the inhibitor solution as the first blank control group; 20 μL of the sodium borate buffer was used instead of the ACE reagent as the second blank control group.

[0047] 2) Chromatographic conditions

[0048] 1) Chromatographic column: Sunfire column C18 analytical ch...

Embodiment 1

[0055] A fermented milk product for lowering blood pressure, which is made by fermenting the following raw materials with lactic acid bacteria strains: 85g fresh buffalo milk, 5g sucrose, 5g buffalo milk blood pressure lowering peptide base, 0.15g taurine; lactic acid bacteria strains added The amount is 0.022836u.

[0056] The preparation method of the buffalo milk hypotensive peptide base material is:

[0057] (1) Raw milk standardization: using fresh buffalo milk as the raw material, defatting it, and adjusting the protein content of the fresh buffalo milk to 4% to obtain standardized buffalo milk;

[0058] (2) Sterilization: heat the standardized buffalo milk obtained in step (1) to 60°C and sterilize for 10 min;

[0059] (3) Adjust the pH value: cooling the buffalo milk obtained after step (2) to 55°C, and adjust the pH value to 10.5;

[0060] (4) Protease hydrolysis: add protease to the water buffalo milk treated in step (3), and hydrolyze it for 3.5 hours at a temperature of 55°...

Embodiment 2

[0069] A fermented milk product for lowering blood pressure, which is made by fermenting the following raw materials with lactic acid bacteria: 88g fresh buffalo milk, 6g sucrose, 8g buffalo blood pressure lowering peptide base, 0.25g taurine; lactic acid bacteria added The amount is 0.0407u.

[0070] The preparation method of the buffalo milk hypotensive peptide base material is:

[0071] (1) Raw milk standardization: using fresh buffalo milk as the raw material, defatting it, and adjusting the protein content of the fresh buffalo milk to 4% to obtain standardized buffalo milk;

[0072] (2) Sterilization: Heat the standardized buffalo milk obtained in step (1) to 65°C and sterilize for 8 minutes;

[0073] (3) Adjust the pH value: cool the buffalo milk obtained after step (2) to 60°C, and adjust the pH value to 10.0;

[0074] (4) Protease hydrolysis: add protease to the buffalo milk treated in step (3), and hydrolyze it for 4 hours at a temperature of 60° C., wherein the buffalo milk i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com