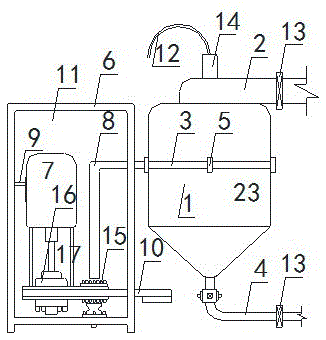

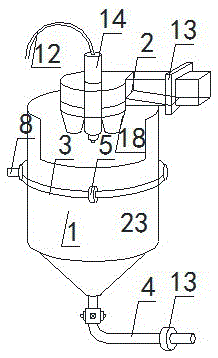

Vibration type atomized evaporative crystallization device

A technology of atomization evaporation and crystallization device, which is applied in the directions of evaporation separation crystallization, spray evaporation, oscillation crystallization, etc., which can solve passive problems and achieve the effect of improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

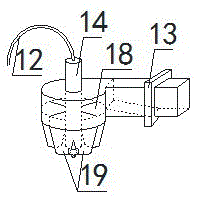

[0033]Take the process of the present invention for treating the bittern water discharged from the saltworks as an example. When the amount of bittern is 50kg / h, the inner diameter of the atomized crystallization chamber 1 is designed to be 1.8m, and the height is 2.5m; the top rectifier 18 of the atomized crystallization chamber 1 has a diameter of 0.9m, and the cross section of the hot air pipe 2 connected with the rectifier 18 The size is 0.8×0.8m. A compensator 13 is set between the hot air pipe 2 and the external pipeline of the equipment to absorb the lateral, longitudinal and axial displacement caused by the high-frequency vibration of the vibration unit 11. The cross-sectional size of the compensator 13 is 1.0× 1.0m; the diameter of the high-speed centrifugal atomizer 14 is 0.225m, the power is 550W, the rotation speed is 2800rpm, the spray volume is adjustable from 0 to 50kg / h, and the diameter of the polytetrafluoroethylene stock solution pipeline 12 connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com