Pneumatic and electric matched automatic loading and unloading device

An automatic loading and unloading and electrical technology, which is applied in metal processing and other directions, can solve the problems of low precision, inconsistent positions, and the inability to add L-shaped workpieces for accurate positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

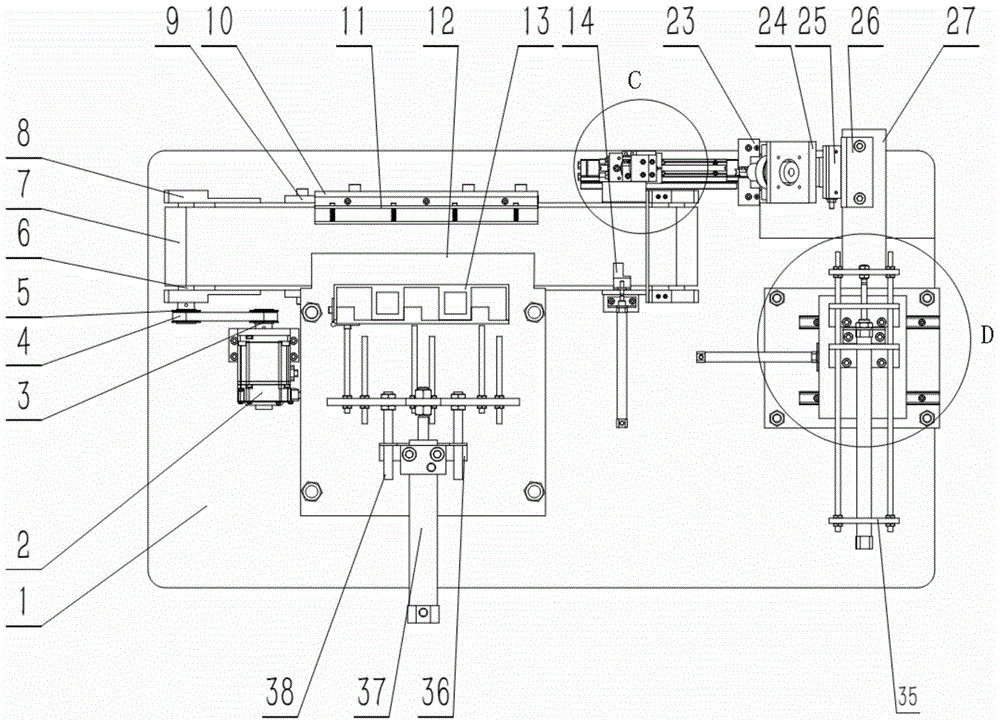

[0021] This embodiment is a pneumatic, electrical and automatic loading and unloading device.

[0022] refer to Figure 1~6 In this embodiment, the pneumatic and electrical automatic loading and unloading device is composed of a control system, a workbench, a feeding mechanism, and a loading and unloading mechanism; the control system adopts PLC + industrial computer control to control the feeding mechanism and the loading and unloading machine, and realize different Institutional independent work. The table provides support for the components.

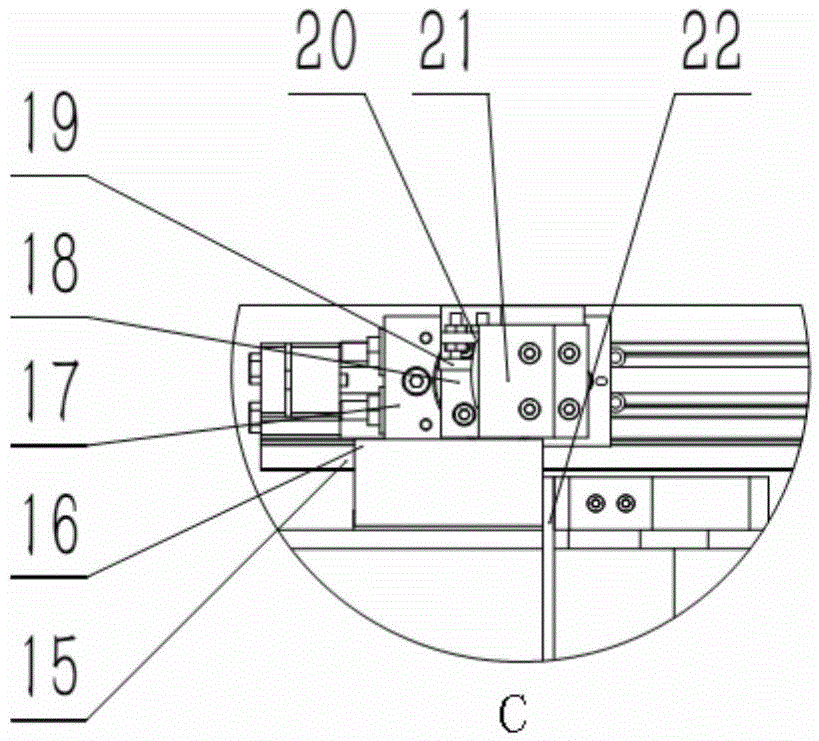

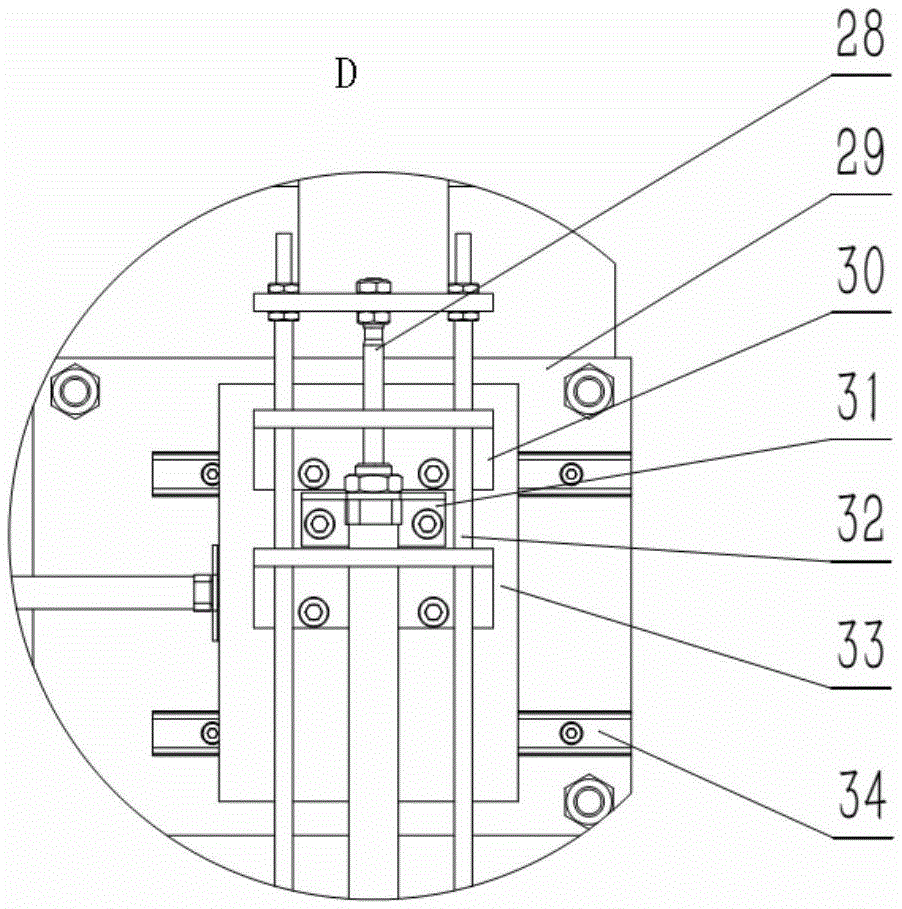

[0023] In this embodiment, the feeding mechanism includes a motor 2, a synchronous pulley 3, a synchronous belt 4, a conveyor pulley 5, a roller 6, a conveyor belt 7, a bearing mounting seat 8, a conveyor belt mounting plate 9, a workpiece lateral positioning plate 10, and a limit mechanism 11 , cylinder mounting plate 12, material storage box 13, cylinder support 36, feeding cylinder 37, guide rod 38, push rod mounting plate 39, wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com