Black smoke agent and preparation method thereof

A fumigant, black technology, applied in the direction of offensive equipment, smoke/mist generation, etc., can solve the problems of health hazards, physical disadvantages, toxicity, etc., and achieve the effects of easy operation, low combustion temperature, and high color purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

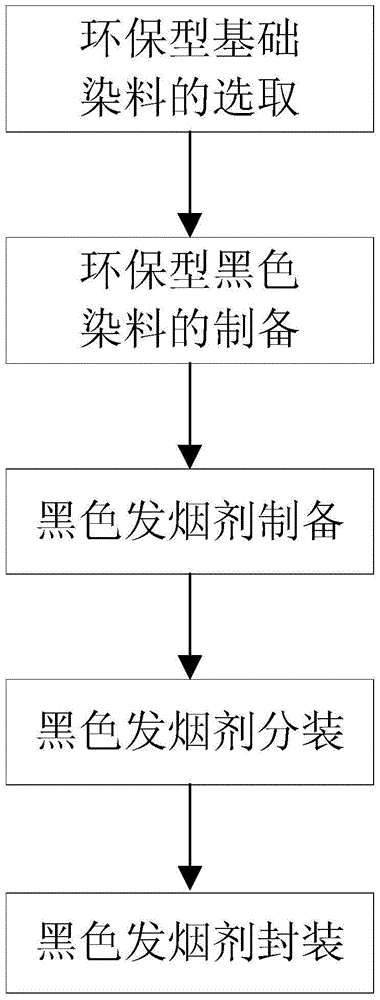

Method used

Image

Examples

Embodiment 1

[0022] 1), accurately weigh 3g of red dye, 4g of yellow dye, and 12g of blue dye, and mix thoroughly to make black dye, and prepare black dye with potassium chlorate, sucrose and ammonium oxalate according to 4.5:3:2:0.5 (mass than) accurately weighed, and evenly mixed to make 30g of black fuming agent, filled into the discharge shell, inserted lead wire and sealed, and ignited to discharge.

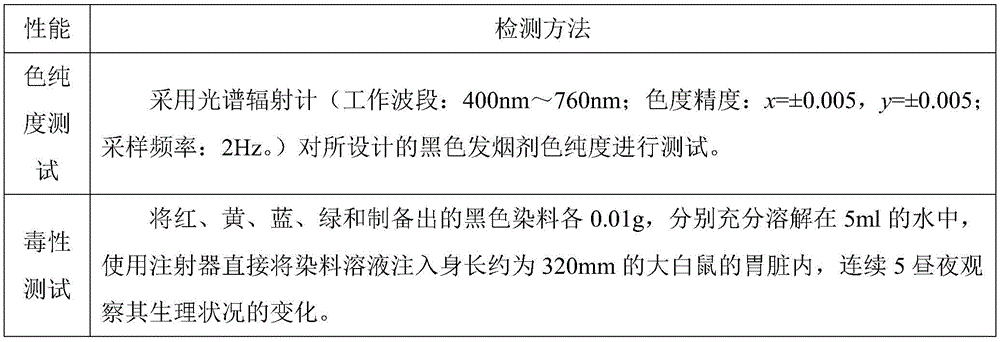

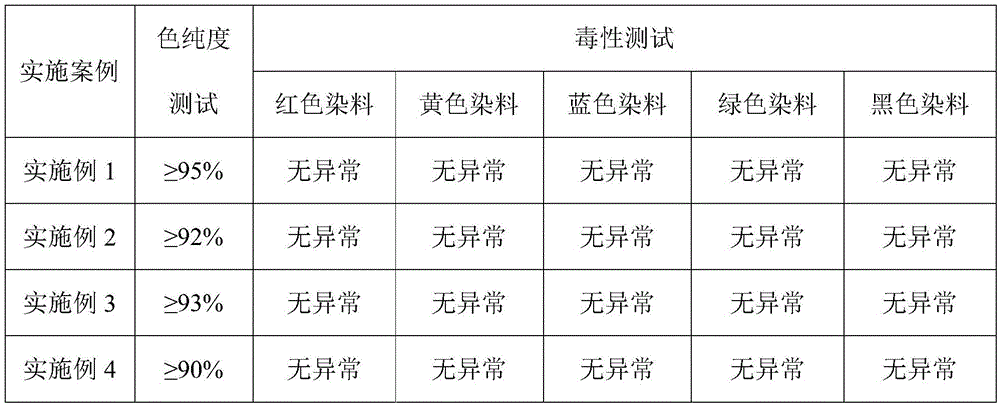

[0023] Test the color purity and dye toxicity when burning with the method shown in Table 1, and Table 2 is the test results.

[0024] The results show that its color purity is more than 95%. After continuous observation for 5 days and nights (120 hours), the physiological condition of the rats injected with the dye has no obvious change.

[0025] Table 1 Test method

[0026]

Embodiment 2

[0027] Embodiment 2: Accurately weigh 3 g of red dye, 4 g of yellow dye, and 10 g of blue dye to make black dye;

[0028] The composite material obtained is used as a dyestuff, and according to the preparation process of the color fuming agent, the composite dyestuff and potassium chlorate, sucrose and ammonium oxalate are accurately weighed according to 4.5:3:2:0.5 (mass ratio), and uniformly mixed to make 30g The black fuming agent is filled into the discharge casing, the lead wire is inserted and sealed, and then ignited and discharged. Test the color purity and dye toxicity when burning with the method shown in Table 1, and Table 2 is the test results. The results show that its color purity is more than 92%. After continuous observation for 5 days and nights (120 hours), the physiological condition of the rats injected with the dye has no obvious change.

Embodiment 3

[0029] Embodiment 3: Accurately weigh 4 g of red dye and 10 g of green dye, and fully mix to obtain black dye;

[0030] Accurately weigh the obtained black dye and potassium chlorate, sucrose and ammonium oxalate according to 4.5:3:2:0.5 (mass ratio), and mix uniformly to make 30g of black fuming agent, fill it into the discharge shell, insert Lead and seal, ignite and set off. Test the color purity and dye toxicity when burning with the method shown in Table 1, and Table 2 is the test results. The result shows that its color purity is more than or equal to 93%. After continuous observation for 5 days and nights (120 hours), there is no obvious change in the physiological condition of the rats injected with the dye.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com