Helicene diphenol hydride, method for preparing same and application of helicene diphenol hydride

A technology for hydrogenating helicene diphenols and helicene diphenols, which is applied in the directions of organic chemistry methods, carbon-based compound preparation, chemical instruments and methods, etc. Symmetrical catalytic effect, correct structure, high product yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

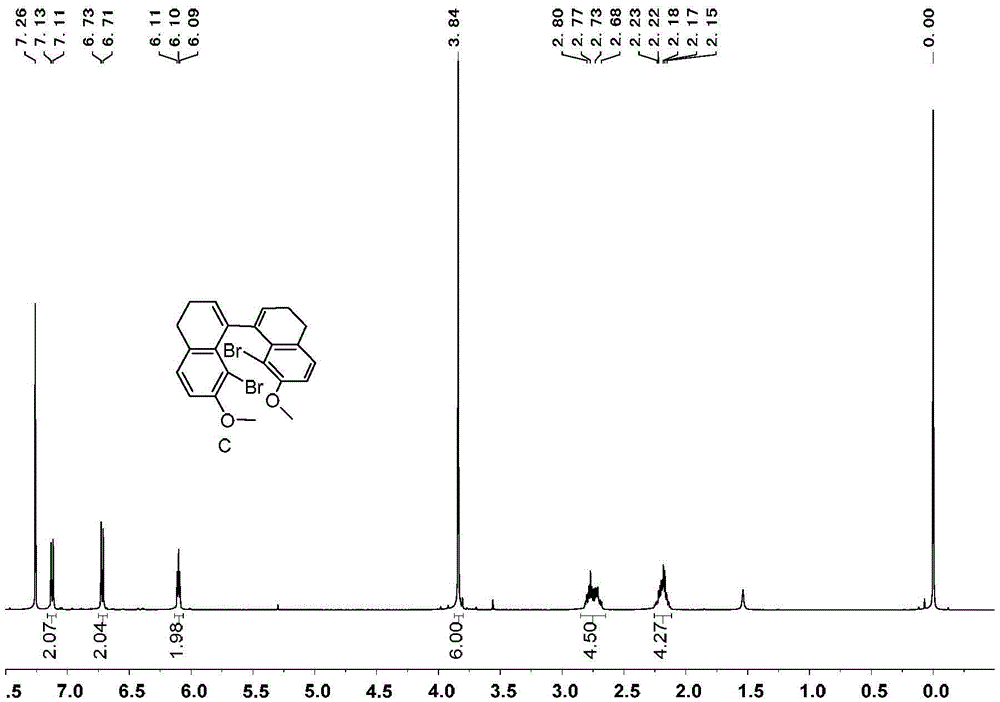

[0071] Embodiment 1, the synthesis of 1,1 '-diphenyl [5] helical diphenol

[0072] 1,1'-diphenyl[5]helicenediol is synthesized according to the following reaction scheme:

[0073]

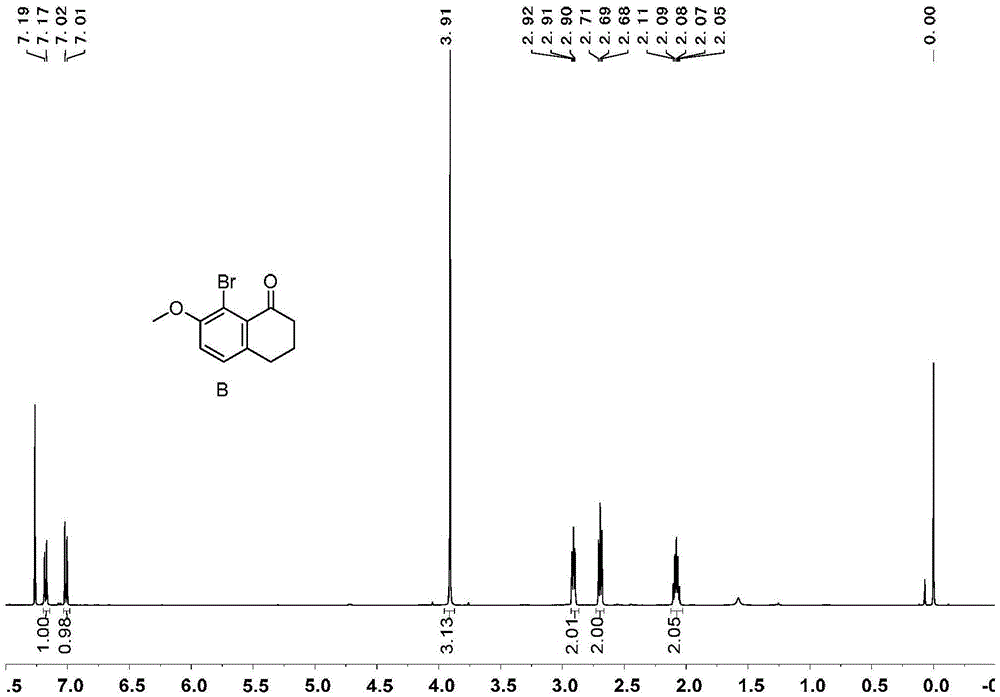

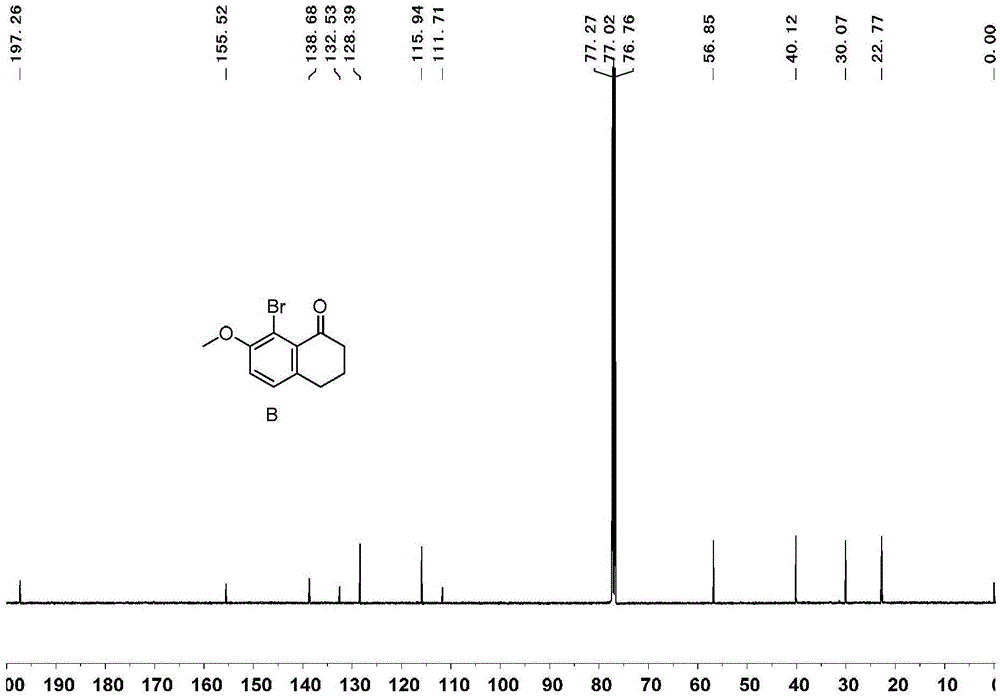

[0074] 1) Add 99g of tetralone, 100g of N-bromosuccinimide, 4g of ferric chloride and 500mL of acetonitrile in sequence in a 1000mL round bottom flask, react at room temperature for 4 hours, add 300mL of water to the reaction system, and precipitate a white solid 143 g of product B, greater than 99% yield.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com