Quaternized organic silicone oil and preparation method thereof

A technology for quaternizing silicone and silicone oil, which can be used in fiber types, textiles and papermaking, fiber processing, etc., and can solve problems such as the use of emulsifiers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

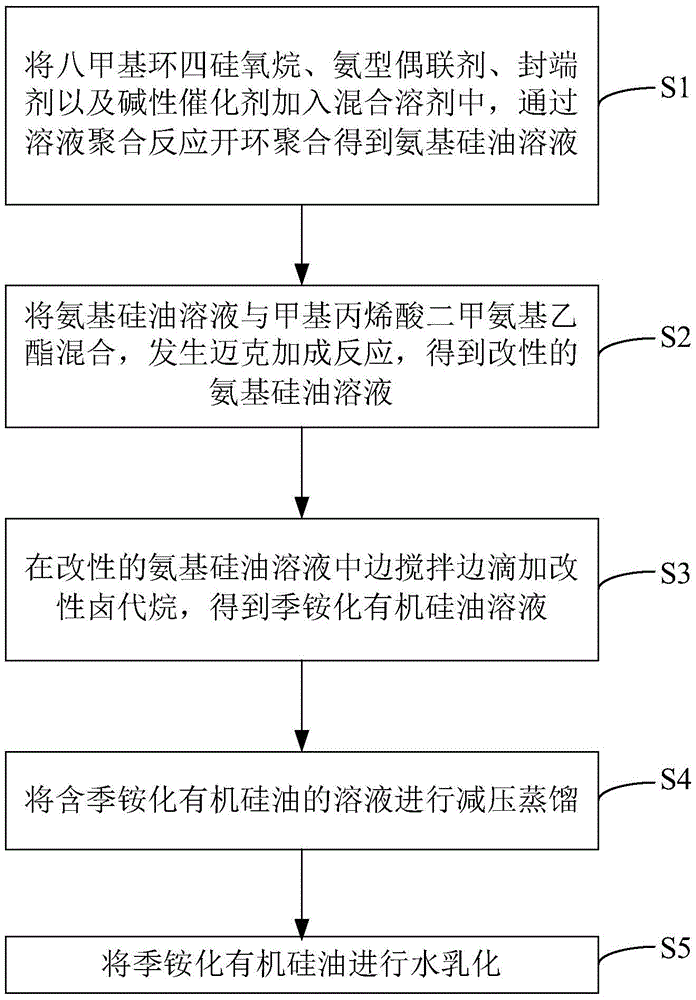

[0026] like figure 1 Shown, the preparation method of the quaternized silicone oil of an embodiment, comprises the steps:

[0027] S1: Add octamethylcyclotetrasiloxane, ammonia type coupling agent, end-capping agent and basic catalyst into a mixed solvent, and obtain an amino silicone oil solution by ring-opening polymerization through solution polymerization.

[0028] Specifically, add octamethylcyclotetrasiloxane, ammonia type coupling agent, basic catalyst and mixed organic solvent into a four-necked flask, and stir the above raw materials evenly at room temperature at a stirring speed of 200-400 rpm . Wherein, the four-necked flask is equipped with a stirrer, a reflux condenser and a thermometer.

[0029] After stirring evenly, heat up to a temperature of 45-75°C. At a stirring speed of 200-400 rpm and a temperature of 45-75°C, octamethylcyclotetrasiloxane and ammonia-type coupling agent are mixed in the basic catalyst Under the influence of reaction for 5-10 hours. Un...

Embodiment 1

[0062] Add 13.0g octamethylcyclotetrasiloxane, 2.5g N-β-(aminoethyl)-γ-aminopropylmethyldimethoxysilane (KH602), 0.08g catalyst potassium hydroxide and 84g mixed solvent In a four-necked flask equipped with a stirrer, a reflux condenser and a thermometer, stir and mix uniformly at a speed of 300rmp / min, then raise the temperature to 50°C, react for 6 hours, and finally add 0.06g of end-capping agent hexamethyldisiloxane, React for 1.5 hours to obtain an amino silicone oil solution, wherein the mixed solvent used is a mixture of toluene and isopropanol, and its mass percentage is 20:80;

[0063] Add dimethylaminoethyl methacrylate to the obtained aminosilicone oil solution, stir and mix evenly at a speed of 300rmp / min, then raise the temperature to 25°C, and react for 15 hours to obtain a modified aminosilicone oil solution, wherein the primary aminosilicone oil The molar ratio of amine to dimethylaminoethyl methacrylate is 1:1.

[0064] At room temperature, under stirring at ...

Embodiment 2

[0068] Add 10.0g octamethylcyclotetrasiloxane, 4g N-β-(aminoethyl)-γ-aminopropylmethyldimethoxysilane (KH602), 0.08g catalyst potassium hydroxide and 84g mixed solvent In a four-necked flask with a stirrer, a reflux condenser and a thermometer, stir and mix evenly at a speed of 300rmp / min, then raise the temperature to 50°C, react for 6 hours, and finally add 0.06g of end-capping agent hexamethyldisiloxane, and react After 1.5 hours, an amino silicone oil solution was obtained, wherein the mixed solvent used was a mixture of toluene and isopropanol, and its mass percentage was 20:80;

[0069] Add dimethylaminoethyl methacrylate to the obtained aminosilicone oil solution, stir and mix evenly at a speed of 300rmp / min, then raise the temperature to 25°C, and react for 15 hours to obtain a modified aminosilicone oil solution, wherein the primary aminosilicone oil The molar ratio of amine to dimethylaminoethyl methacrylate is 1:1.

[0070] At room temperature, under stirring at a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com