Polyaniline/liquid crystal elastomer composite membrane material and preparation method thereof

A liquid crystal elastomer and polyaniline technology, applied in the field of photothermal functional polymers, can solve the problems of poor compatibility and low stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

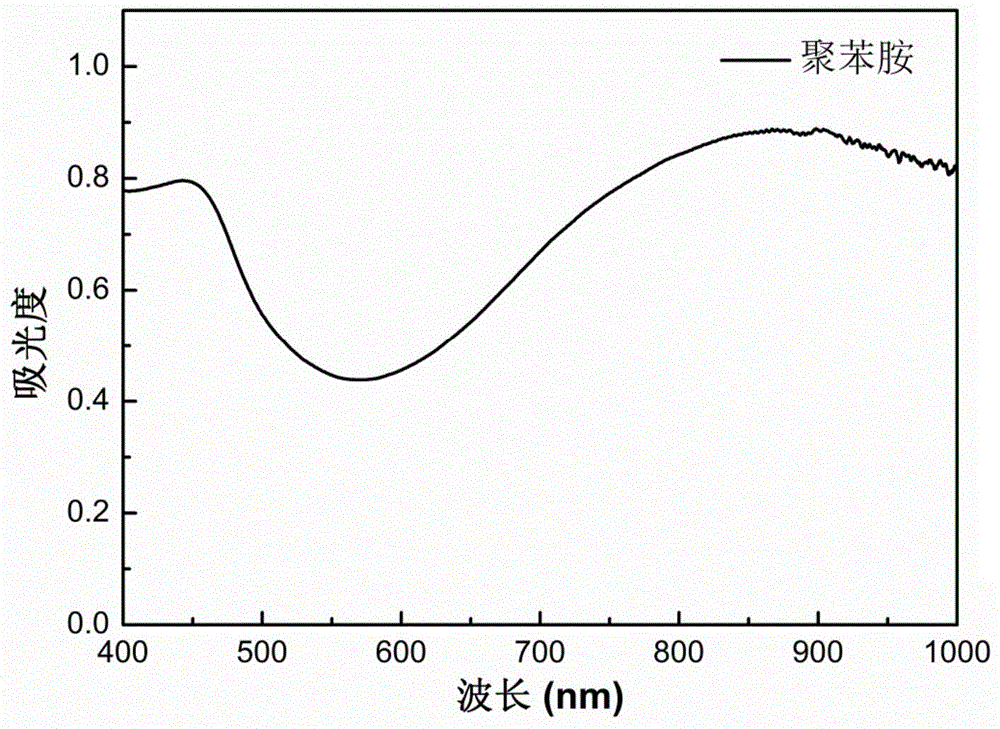

[0030] Preparation of Polyaniline / Liquid Crystal Elastomer Composite Membrane Material

[0031] Dissolve polymethylsiloxane, liquid crystal monomer, olefin crosslinking agent containing terminal double bonds, and polyaniline in a mass ratio of 36:150:21:(1~20) in toluene, and ultrasonically disperse at room temperature for 5~ After 10 minutes, transfer to a polytetrafluoroethylene tank, add 45 parts of platinum catalyst solution, and continue ultrasonication for 10 to 20 minutes to remove air bubbles. Put the polytetrafluoroethylene tank in an oven at 60 to 65°C for thermal crosslinking for 2 to 4 hours, wait until the toluene solvent is completely volatilized, add a small amount of n-hexane to the polytetrafluoroethylene tank to soak, remove the film for stretch orientation . Put it back into an oven at 60 to 65° C. to continue thermal crosslinking for 24 to 48 hours to obtain a polyaniline / liquid crystal elastomer composite film material.

[0032] The polymethylsiloxane st...

Embodiment 1

[0042]Add 18.9 g (0.2 mol) of aniline liquid into 300 mL of aqueous hydrochloric acid solution with a concentration of 1 mol / L, and stir for 30 minutes under ice-cooling. Add 11.41 g (0.05 mol) of ammonium persulfate dissolved in 200 mL of 1 mol / L HCl solution dropwise. The temperature was kept below 5°C all the time with magnetic stirring for 6 hours. After the reaction was completed, the stirring was stopped, and the reaction solution was filtered, washed, and finally vacuum-dried at 40° C. for 24 hours to obtain 6.5 g of polyaniline solid powder with a yield of 34.4%.

Embodiment 2

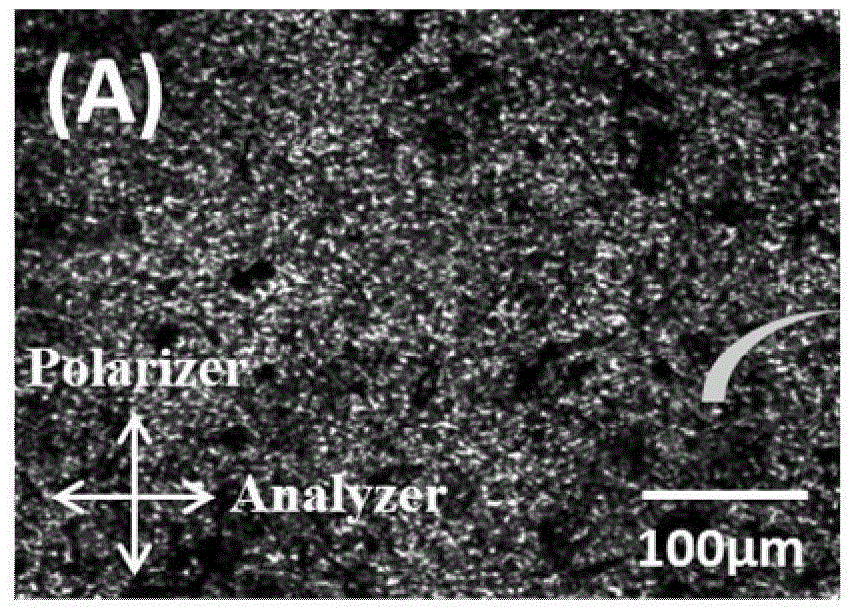

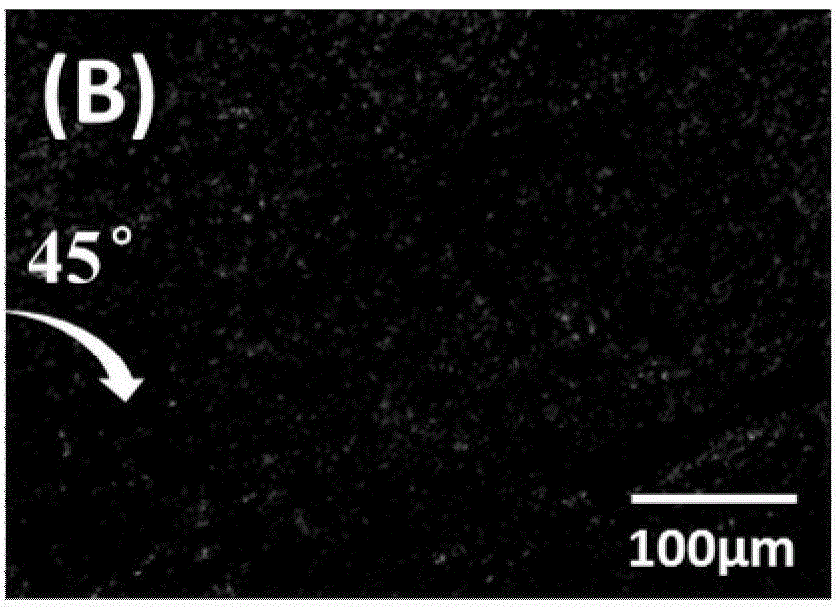

[0043] Example 2: Preparation of conjugated polymer / liquid crystal elastomer light-to-heat conversion film material and its elongation and maximum load-bearing determination:

[0044] 36mg (0.6mmol) of polymethylsiloxane 150mg (0.5mmol) monomer 21 mg (0.05 mmol) crosslinker and 1 mg polyaniline Put them together into a brown vial containing 2mL of toluene, and the mass fraction of conjugated polyaniline in the total charge is 0.48%. Ultrasound for 10 minutes to disperse evenly, transfer to a 2cm×2cm×2cm polytetrafluoroethylene tank, add 45μL of Pt(COD)Cl 2 Catalyst solution, sonicate again for 15 minutes to remove air bubbles in the toluene solution. Pre-crosslink in an oven at 60 to 65°C for 2 to 4 hours. After the toluene solvent is completely volatilized, take out the polytetrafluoroethylene tank, cool to room temperature, add a small amount of n-hexane in the tank and soak for 2 minutes, take off the film for stretching orientation, and the elongation of the film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com