Crude oil continuous distillation and dehydration method

A technology of crude oil and dehydration device, which is applied in the dehydration of hydrocarbon oil, etc., and can solve the problems of energy consumption, time consumption, and limited amount of dehydrated crude oil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

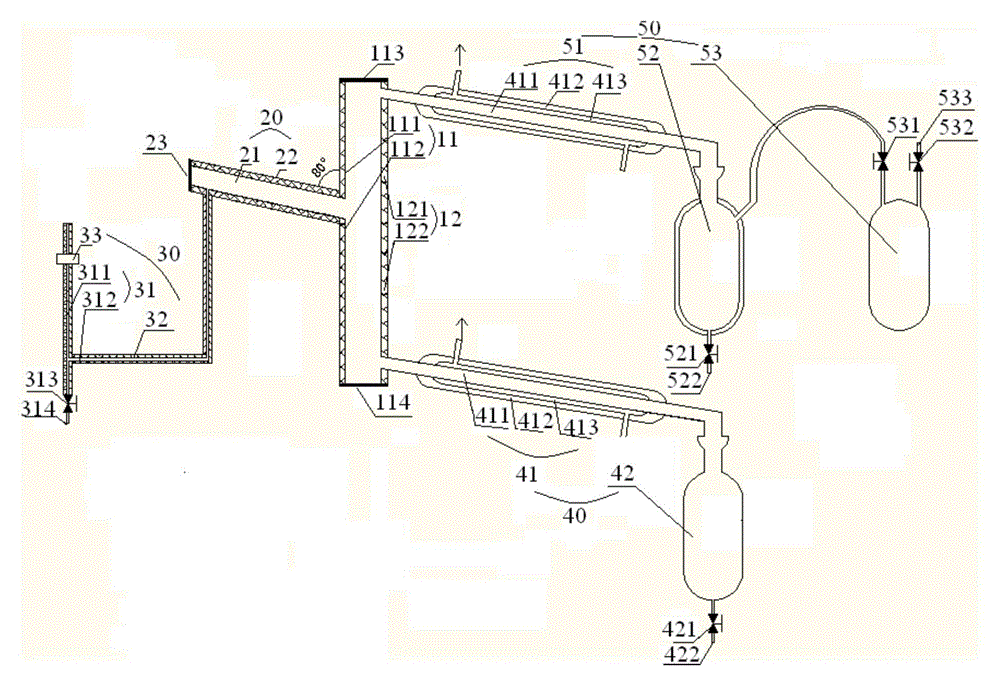

Image

Examples

Embodiment 1

[0084] Turn on the power, set the temperature of the temperature-controllable feed pump 33 and the third heater 32 to 50° C. according to the freezing point and viscosity of the crude oil, and keep it for 10 minutes. The temperature of the second heater 22 and the upper heater 121 was set to 200°C, and the temperature of the lower heater 122 was set to 250°C. Set the temperature of the second cooling component 51 and the light oil and water storage tank 52 to 1°C, and set the temperature of the first cooling component 41 to 60°C. The cooling temperature of the gaseous hydrocarbon recovery tank 53 is -90°C.

[0085] Crude oil with a water content of 53.1% by mass was dehydrated at a temperature-controllable feed pump (gear pump) flow rate of 16ml / min. The distillation time for light oil and heavy oil was 5 minutes, and the dehydration time was 230 minutes. The mass of crude oil feed was 3099 grams, the mass of extracted water was 1639 grams, the water content of dehydrated cru...

Embodiment 2

[0087] Set the temperature of the temperature-controllable feed pump 33 and the third heater 32 to 100° C. and keep it for 10 minutes. The temperature of the second heater 22 and the upper heater 121 was set to 300°C, and the temperature of the lower heater 122 was set to 300°C. Set the temperature of the second cooling assembly 51 and the light oil and water storage tank 52 to 10°C, and set the temperature of the first cooling assembly 41 to 100°C. The cooling temperature of the gaseous hydrocarbon recovery tank 53 is -100°C.

[0088] The crude oil with a water content of 1.1% by mass is dehydrated at a temperature-controllable feed pump (gear pump) feed rate of 16ml / min. The distillation time of light oil and heavy oil is 5 minutes, and the dehydration time is 230 minutes. The material quality is 3204 grams, the crude oil dehydrated water quality is 35 grams, and the water content of dehydrated crude oil is trace (<0.03 mass %). The calculated crude oil dehydration rate is ...

Embodiment 3

[0090] Set the temperature of the temperature-controllable feed pump 33 and the third heater 32 to 20° C. and keep it for 10 minutes. The temperature of the second heater 22 and the upper heater 121 was set to 200°C, and the temperature of the lower heater 122 was set to 250°C. Set the temperature of the second cooling component 51 and the light oil and water storage tank 52 to 1°C, and set the temperature of the first cooling component 41 to 60°C. The cooling temperature of the gaseous hydrocarbon recovery tank 53 is -90°C.

[0091] The crude oil with a water content of 63.6% by mass is dehydrated at a temperature-controllable feed pump (gear pump) feed rate of 16ml / min. The distillation time of light oil and heavy oil is 5 minutes, and the dehydration time is 390 minutes. The mass of the raw material is 5311 grams, the mass of dehydrated water is 3314 grams, the water content of the dehydrated crude oil is 3.2 mass %, and the dehydration rate of the crude oil is calculated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com