Method for preparing coal water slurry through mixing of reverse osmosis membrane (RO) sewage and VAE emulsion waste water

A technology of coal-water slurry and emulsion, which is applied in the field of preparing coal-water slurry by mixing RO sewage and VAE emulsion wastewater, can solve the problems of insufficient salt content and waste of energy, and achieves the improvement of reused water production, huge economic benefits and energy saving. The effect of water benefits, significant economic benefits and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

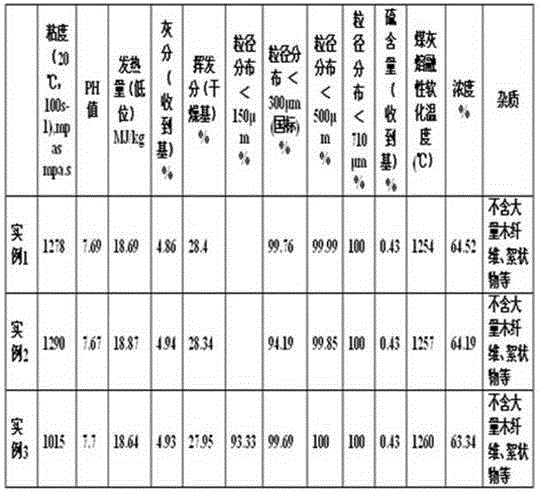

Examples

Embodiment 1

[0020] 27 parts of RO membrane high-salt wastewater were adjusted to pH 7 with hydrochloric acid and mixed with 8 parts of VAE emulsion. Then, 63.65 parts of coal and 1.2 parts of dispersant were added to the mill for grinding, and then 0.15 parts of stabilizer was added to make a slurry.

Embodiment 2

[0022] 10 parts of RO membrane high-salt wastewater was adjusted to pH 7 with hydrochloric acid and mixed with 26 parts of VAE emulsion. Then, 62.9 parts of coal and 1 part of dispersant were added to the mill for grinding, and then 0.1 part of stabilizer was added to make a slurry.

Embodiment 3

[0024] 18 parts of RO membrane high-salt wastewater were mixed with 18 parts of VAE emulsion after adjusting the pH to 7 with hydrochloric acid, then added 62.5 parts of coal and 1.3 parts of dispersant into the mill for grinding, and then added 0.2 parts of stabilizer and then ground into a slurry.

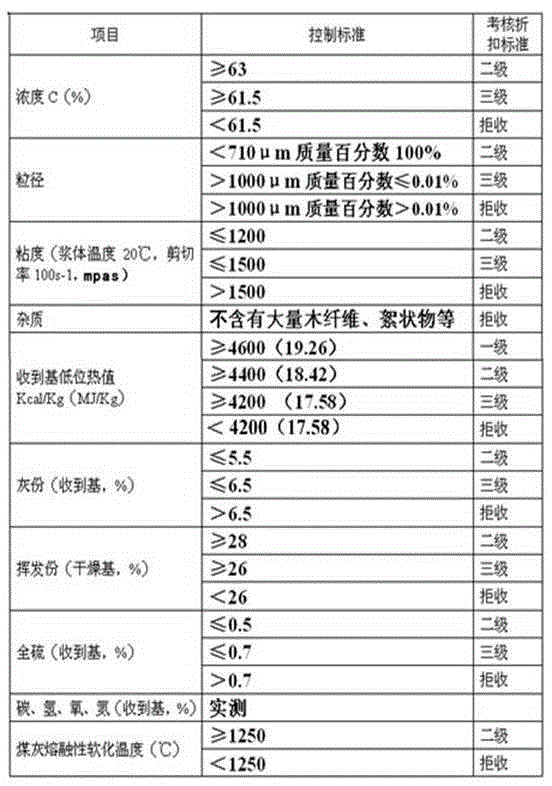

[0025] The parameter of the coal-water slurry that each embodiment obtains sees the following table:

[0026]

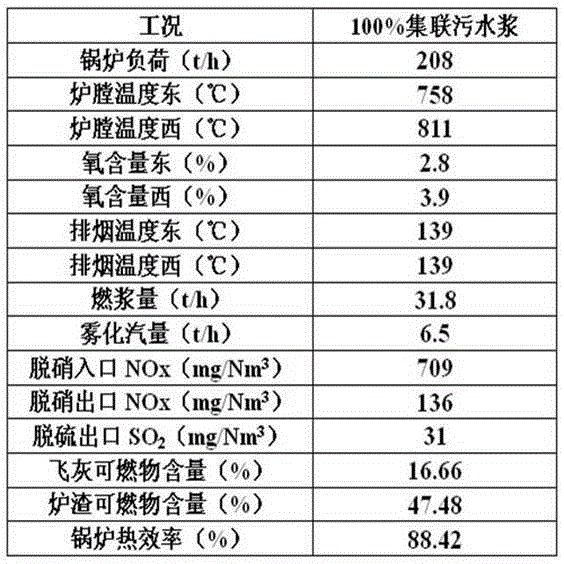

[0027] Burning effect:

[0028]

[0029] Through the above table data, it is verified that the coal water slurry produced by RO sewage and VAE emulsion wastewater meets the quality standard requirements of coal water slurry, and is used normally in the boiler and the flue gas environmental protection discharge meets the Beijing "Boiler Air Pollutant Emission Standard" 21148-2007DB standard requirement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com