Efficient air cooling structure for converter slag-stopping mechanism

An air-cooled structure, converter slag blocking technology, applied in the direction of manufacturing converters, etc., can solve the problems of easy scalding of construction workers, insufficient air-conditioning pressure, small flow rate and flow rate, etc., to achieve good air-cooling effect, reliable flow and pressure. Variable, reliable cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

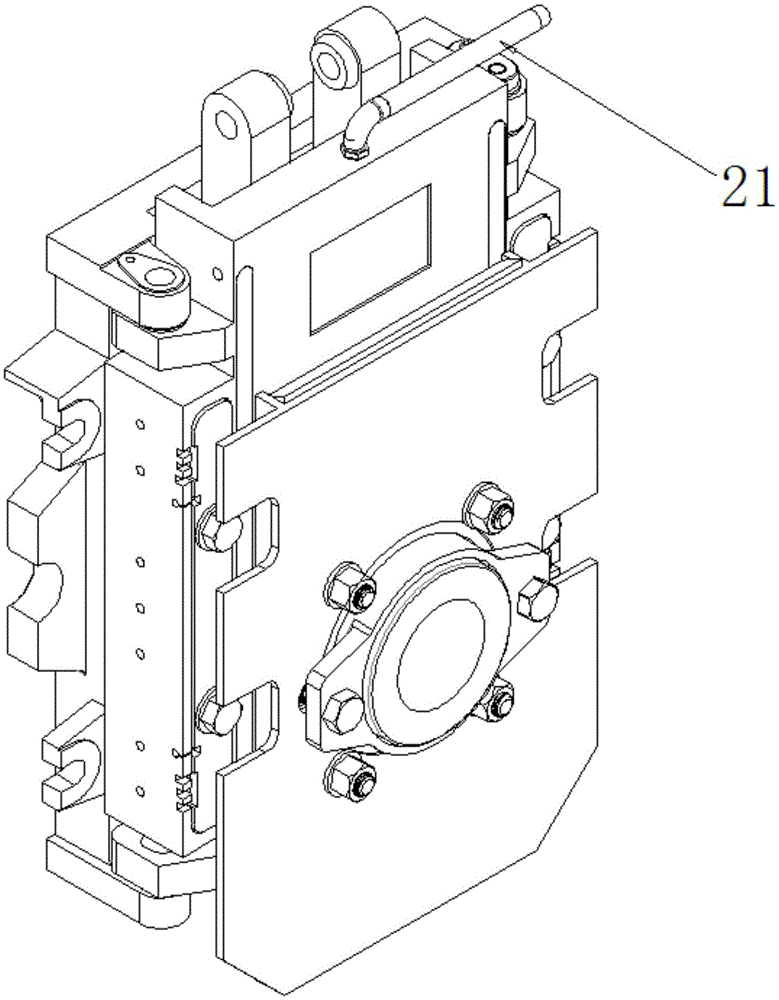

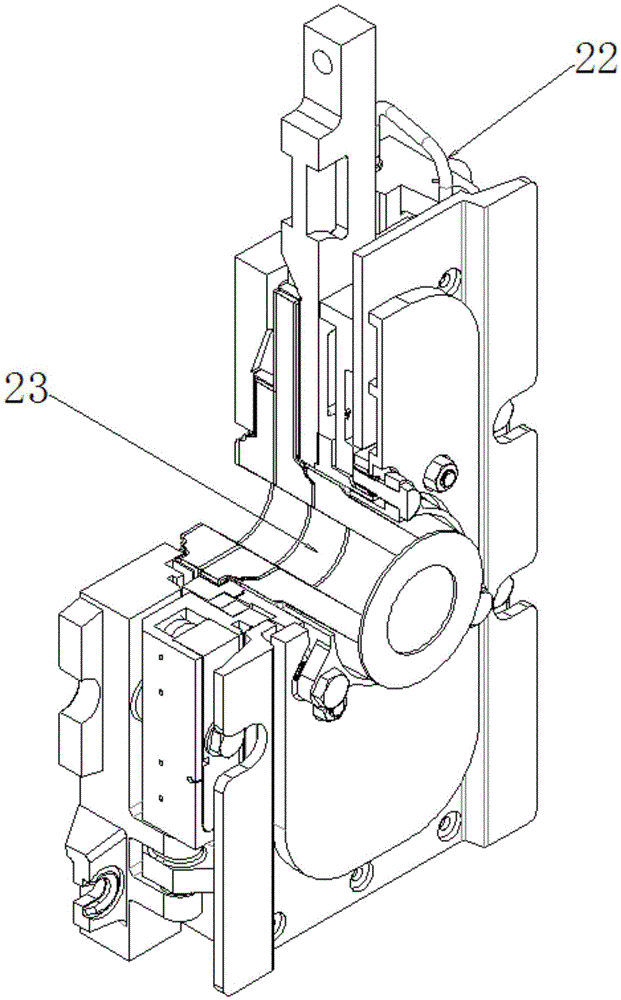

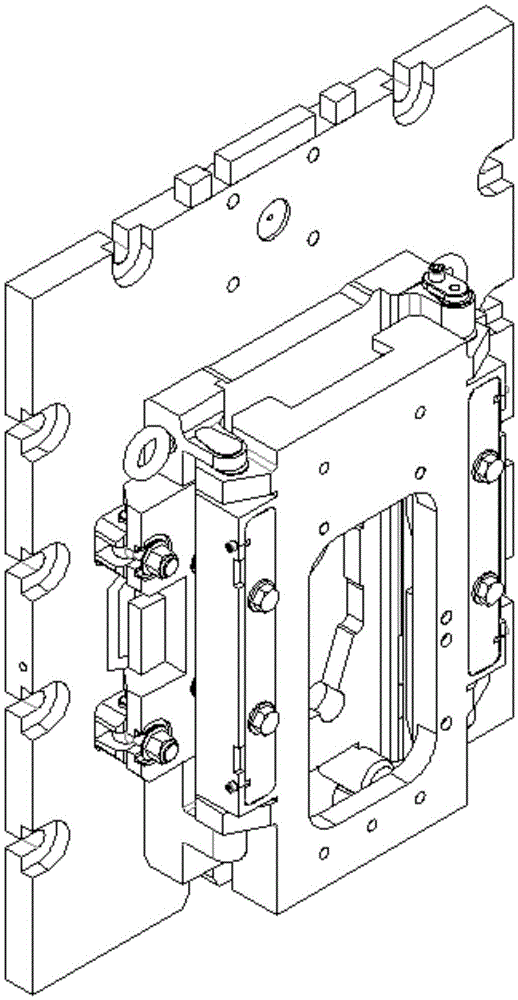

[0018] From image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 It can be seen that the high-efficiency air-cooled structure of the converter slag blocking mechanism of the present invention includes a connecting assembly body 2, an installation assembly body 5, and a tensioning assembly; the left and right ends of the connecting assembly body 2 are respectively provided with an air inlet 3 symmetrically, and the upper Two air outlets 4 are respectively arranged symmetrically on the left and right, and each air inlet 3 is connected to the upper and lower two air outlets 4 through the air-cooled passage; Four mounting holes, welding nut seats 6 in the mounting holes; the tensioning assembly includes a tensioning assembly body 12, an elastic element 7, a pressing panel 8, and a tensioning bolt 9, and blind grooves are symmetrically arranged on the tensioning assembly body 12 left and right 10. An air outlet 14 is provided at the upper and lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com