Environment-friendly and safe printing paste and printing color paste as well as application of printing paste and printing color paste

A printing color paste and printing paste technology, applied in the field of textile dyes, can solve the problems of long paste making time, unstable viscosity, and intolerable storage, and achieve the effects of short paste making time, easy washing and depasting, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) Prepare printing paste:

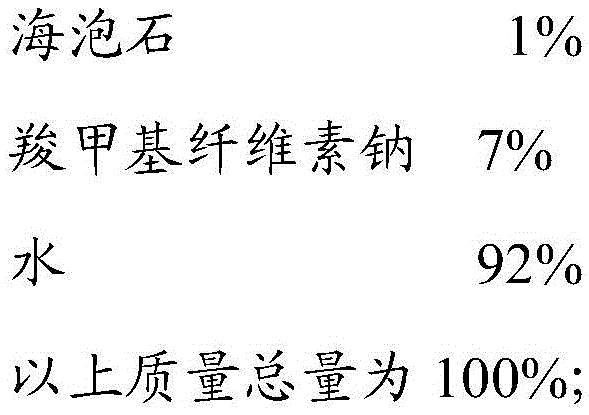

[0035] The printing paste formula is:

[0036]

[0037] According to the above printing paste formula, quantitatively weigh the sodium carboxymethyl cellulose specified in the formula and mix it directly with water, and mix it with electric stirring to make a colorless transparent paste glue, then add the specified amount of sepiolite, and continue stirring for 15 minutes , to obtain printing paste; the paste retains a sample for basic performance testing, and the results are shown in Table 1 below;

[0038] 2) Prepare printing paste

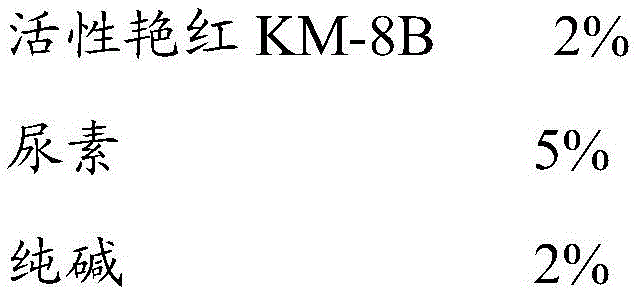

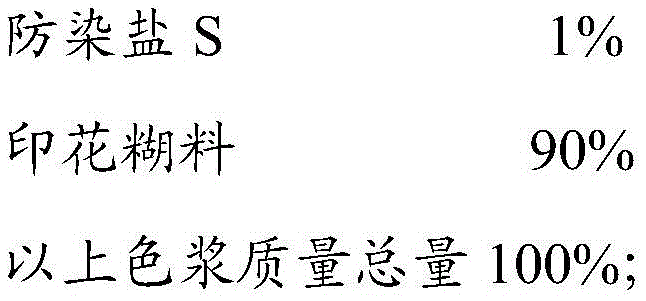

[0039] Printing paste formula:

[0040]

[0041]

[0042] According to the printing paste formula, sequentially add the reactive dyes and printing auxiliaries required by the formula into the printing paste, and stir evenly to obtain the printing paste;

[0043] 3) Lay the pure cotton fabric on the printing conveyor belt, pour the prepared color paste into the printing screen frame, start the print...

Embodiment 2

[0048] 1) Prepare printing paste:

[0049] The printing paste formula is:

[0050]

[0051] According to the above printing paste formula, quantitatively weigh the sodium carboxymethyl cellulose specified in the formula and mix it directly with water, and mix it with electric stirring to make a colorless transparent paste glue, then add the specified amount of sepiolite, and continue stirring for 15 minutes , to obtain printing paste; the paste retains a sample for basic performance testing, and the results are shown in Table 1 below;

[0052] 2) Prepare printing paste

[0053] Printing paste formula:

[0054]

[0055] According to the printing paste formula, sequentially add the reactive dyes and printing auxiliaries required by the formula into the printing paste, and stir evenly to obtain the printing paste;

[0056] 3) Lay the pure cotton fabric on the printing conveyor belt, pour the prepared color paste into the printing screen frame, start the printing machine,...

Embodiment 3

[0061] 1) Prepare printing paste:

[0062] The printing paste formula is:

[0063]

[0064] According to the above printing paste formula, quantitatively weigh the sodium carboxymethyl cellulose specified in the formula and mix it directly with water, and mix it with electric stirring to make a colorless transparent paste glue, then add the specified amount of sepiolite, and continue stirring for 15 minutes , to obtain printing paste; the paste retains a sample for basic performance testing, and the results are shown in Table 1 below;

[0065] 2) Prepare printing paste

[0066] Printing paste formula:

[0067]

[0068] According to the printing paste formula, sequentially add the reactive dyes and printing auxiliaries required by the formula into the printing paste, and stir evenly to obtain the printing paste;

[0069] 3) Lay the pure cotton fabric on the printing conveyor belt, pour the prepared color paste into the printing screen frame, start the printing machine,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com